Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

How do you Engineer Efficiently?

Stop Duplicating Work

I love walking. But walking up and down the warehouse 20 times to find everything I need is not my idea of fun. Why isn’t my warehouse arranged as well as IKEA so that I only have to walk around it once to get everything that I need? It’s exactly the same with engineering.

Are you duplicating your work? Do you copy and paste from different projects to create a schematic? Is every schematic and macro different? If so, it’s time to bring order to this chaos.

Standardisation is Key

Efficient engineering starts with standardising, modularising, and utilising functional structures in an engineering data platform. Standardising isn’t something that limits your creativity, but is something that you already do: reusing schematics! Which components do you use the most? How are the similar and different? And what information isn’t needed? Which options and variants are there? What are the specific customer requirements? By answering these questions, you lay the foundation for standardisation. To do this successfully, it is important for you and engineers from different disciplines to agree on the structuring and definitions.

As an electrical engineer, you take the agreed structure and modules and create macros from them and store them in a macro library. It is then best to check your parts database again to be certain there aren’t any errors. This is important because the parts database it all the centre of all your future engineering so it needs to be right. Are all of the basics filled in? Think about length, width and height. Have you made all of your macros and connected them in 3D? If a part is added, make sure that the correct information is filled in to prevent you from having to do double the work later on. I would include the following items: order number, description, length, width, height, 3D macro, schematic macro, and perhaps weight, drilling template and associated picture.

Macros make standardising easy.

Functional Design

How do you design functionally? And how does functional design help you?

- Everything is on one sheet making it easy to see all of the information you need.

- You can insert and re-position drawings in a fraction of time.

- Value sets can be used in designs to select parts; this doesn’t work if the drawing is split over numerous sheets.

- Every design is tested in advance to check that it meets the requirements and standards.

- Once it has been tested and approved, the design can be used in production and manufacturing. As the design has already been tested and approved, there are less mistakes, which saves you time in the long run.

- The design is consistent because it has been set up correctly. This prevents mistakes from creeping into the schematics, which is important because a mistake at this stage would cost tenfold in the production and would cost thousandfold in the commissioning.

Would you like to know more about functional design?

Integrating with Panel Building

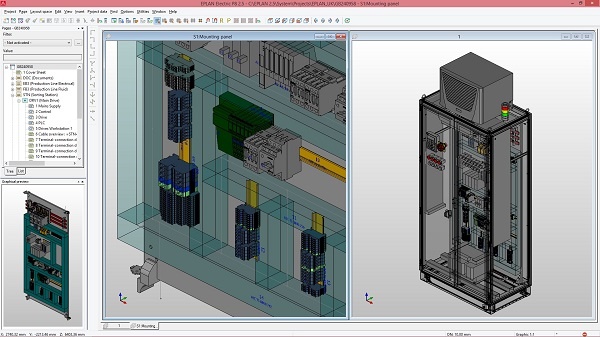

How is designing functionally beneficial for the workshop? You save time because the software has already ensured that the wiring route is correct and the components have been positioned correctly because the model is in 3D. This means that the panel builder receives the correct information to build and wire the control panel.

EPLAN Pro Panel - 3D design

The end user and the service technician from your company also benefit from functional design because they only have to consult one drawing to find what they are looking for instead of searching through lots of drawings.

Comments