Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

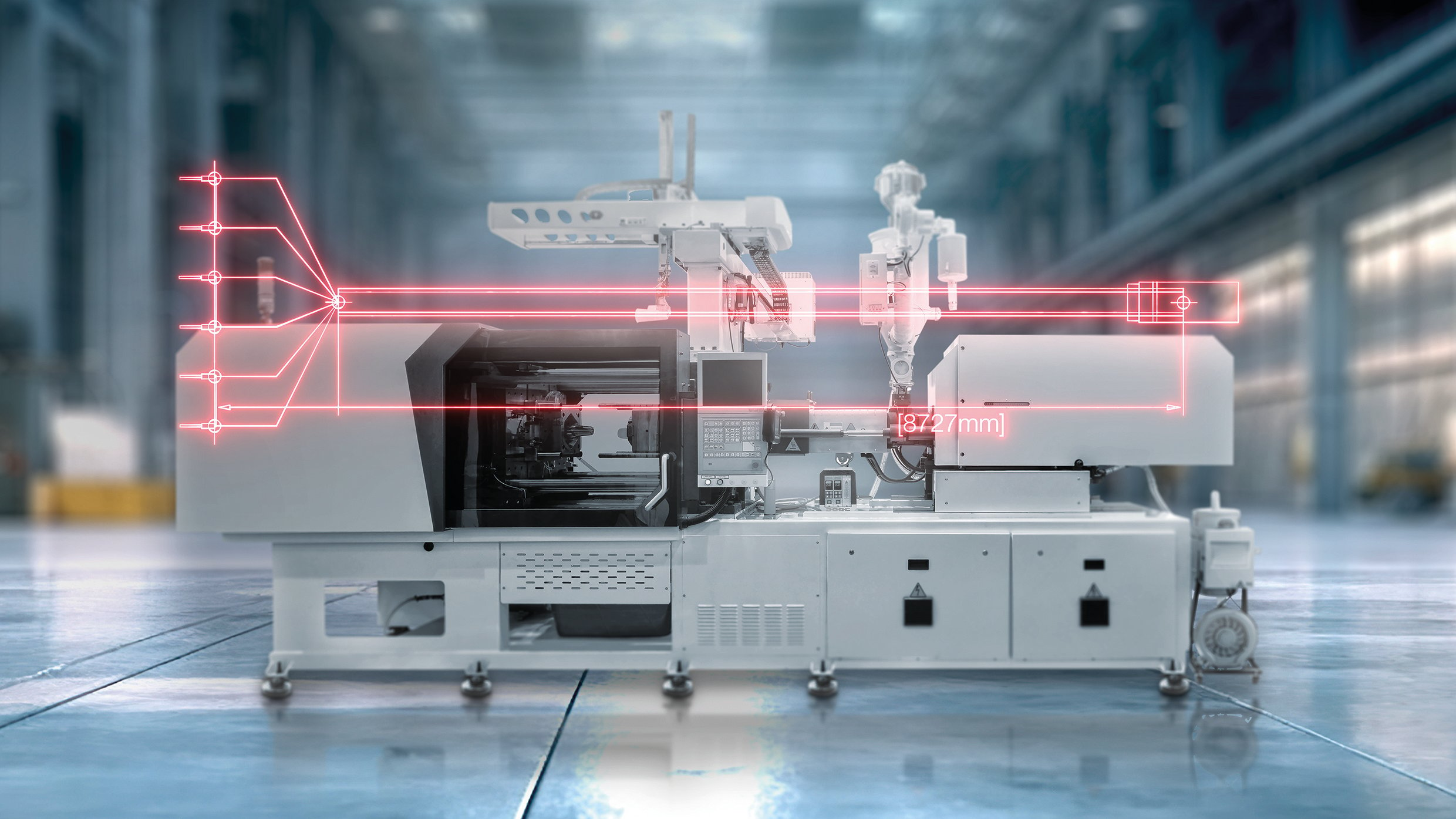

Fast and precise cabling with Eplan Cable proD

What comes to mind when you say ‘shuttle’? Is it a coach taking soccer fans from the stadium to the train station on a Saturday afternoon, or maybe a bus taking trade fair visitors from their cars to the exhibition halls? Both are correct; however, transporting people from A to B isn’t the only shuttle function. The term also covers vehicles that autonomously transport goods.

Often found in small parts warehouses, these vehicles are part of a sophisticated logistics system where boxes or containers are picked up and transported along many different horizontal routes. These vehicles often dart back and forth simultaneously to get goods to their designated locations. This is a common example of sophisticated logistics, and the shuttle technology is one building block of so-called intralogistics (internal company logistics) solutions.

Intralogistics not only refers to warehouse technology, but also includes lifting equipment, industrial trucks, cranes and much more. These systems and equipment have undergone continuous development in recent years and are increasingly offering more complex options for organising and controlling material flows. Faster computers and improved control systems primarily accompany the growing degree of automation.

Family businesses with special expertise

One company specialising in those solutions is psb intralogistics, based in Pirmasens, Rhineland-Palatinate. The family-owned company focuses on customised systems for clients from various industries. This requires a great deal of technical expertise: according to the company, the strength of psb, founded in 1887 as a locksmith’s shop by Franz Klein, lies in the comprehensive know-how of its approximately 550 employees. With its modern and technically sophisticated solutions, psb intralogistics serves industries with high standards. For example, in the pharmaceutical industry, where batch tracking and strict adherence to best-before dates play an important role. In order to guarantee this, psb intralogistics keeps production, design, and development in-house. Its credo is that only those who design, implement, and programme all elements of a system themselves can be the good and reliable partner needed throughout the system’s entire service life.

Working on a shuttle that is used in logistics solutions (photo: psb intralogistics GmbH)

Eplan Cable proD for implementing sophisticated technology

The specialised company also holds patents for various developments. One example is the “Multi Access Warehouse,” a particularly powerful high-bay warehouse in which the shuttles are used. “Over the last few years, we have sold more and more of these shuttles,” reports Dirk Fabricius, who is responsible for the electrical design of the small speedsters at psb intralogistics. He and his team use various Eplan solutions for this purpose. “In the past, this was done on the side, for example, when creating articles and adding a macro here and there. But we now use Eplan in a completely different way. Because, of course, it is our goal that everything fits together in the design – preferably right from the very beginning.”

When Dirk Fabricius says “everything,” he also means steps such as the construction of cables. Depending on their size and number of sensors and actuators, shuttles can have anywhere from 30 to 50 of these. The cables must all be positioned correctly in order to fulfil their function. In this particular case, you can't just lay meter-long loops anywhere – that would interfere with the delicate technology. “Everything has to be accurate to the precise centimetre,” says Fabricius.

That is the moment where Eplan Cable proD comes into play. psb intralogistics has been using the solution for about a year to precisely position cables. “Previously, we tended to neglect the issue of cabling,” says Fabricius, referring to their former approach. “Then the cables were often a little too long during our in-house tests, and sometimes even too short. In both cases, they had to be adjusted afterwards, resulting in extra work, delayed assembly and higher costs. After all, we're talking about a good 100 or even 200 shuttles in total.” The sheer number of cable corrections caused delays – and thus incurred costs. This is no longer the case with the Eplan Cable proD. This software solution provides the electrical designers' team, headed by Dirk Fabricius, with a 3D layout of the shuttle from the mechanical engineering department, enabling them to lay the cables virtually.

The 3D model of a shuttle vehicle is used in Eplan Cable proD for cable design (Photo: psb intralogistics GmbH)

Whereas there is no immediate return on investment (particularly in the beginning), and engineering takes a little longer than before, Dirk Fabricius explains, the effort still pays off relatively quickly. “In my opinion, you can see the first benefits from the third design onwards – after that, the additional time invested in engineering is recouped. And from project to project, the amount of extra work becomes a little less.”

Testing phase proves to be promising

Dirk Fabricius and his team started last year with a three-day-training course on Cable proD. “We do have experienced in-house ‘Eplaners’, but Cable proD is a completely self-sufficient program. That's why we took some time to get to grips with it again.” psb intralogistics is currently still testing this Eplan software – but it looks like it will be the tool of choice. “We also tried out competing systems. However, these had the disadvantage of being too complicated to use. With Eplan Cable proD, on the other hand, we can import data from other Eplan solutions and use it directly,” says Dirk Fabricius. This is an advantage that technology leader psb is likely to continue building on in the future to ensure everything will keep getting from A to B fast.

Comments