Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

PLM integration: 3D cable information directly integrated into Teamcenter

For cross-application collaboration with EPLAN, there are various integrations that enable data exchange with common ERP, PLM and PDM systems - including standard interfaces to Siemens Teamcenter and PTC Windchill. The products in the PLM environments can almost without exception be enhanced with ECAD data such as circuit diagrams.

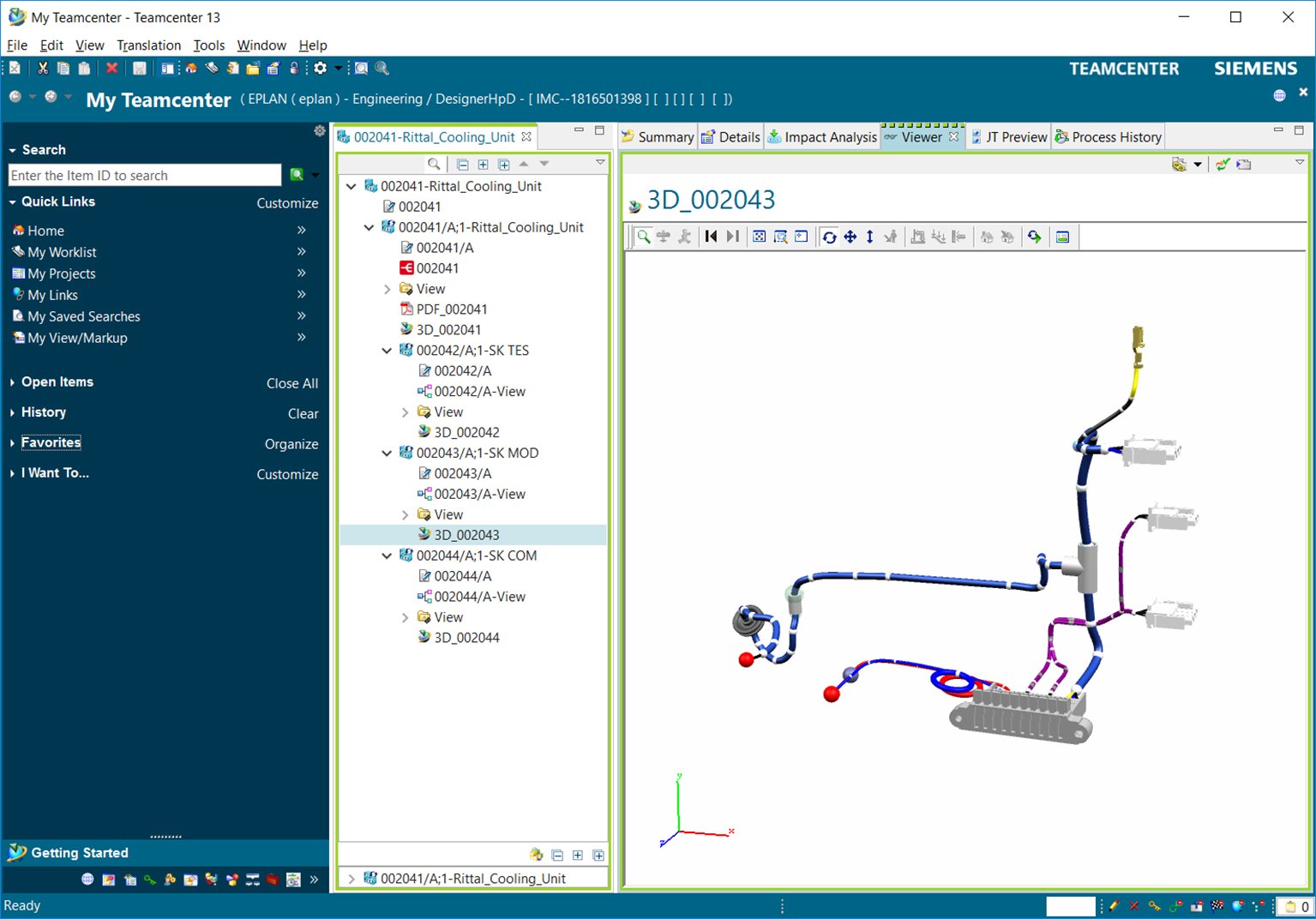

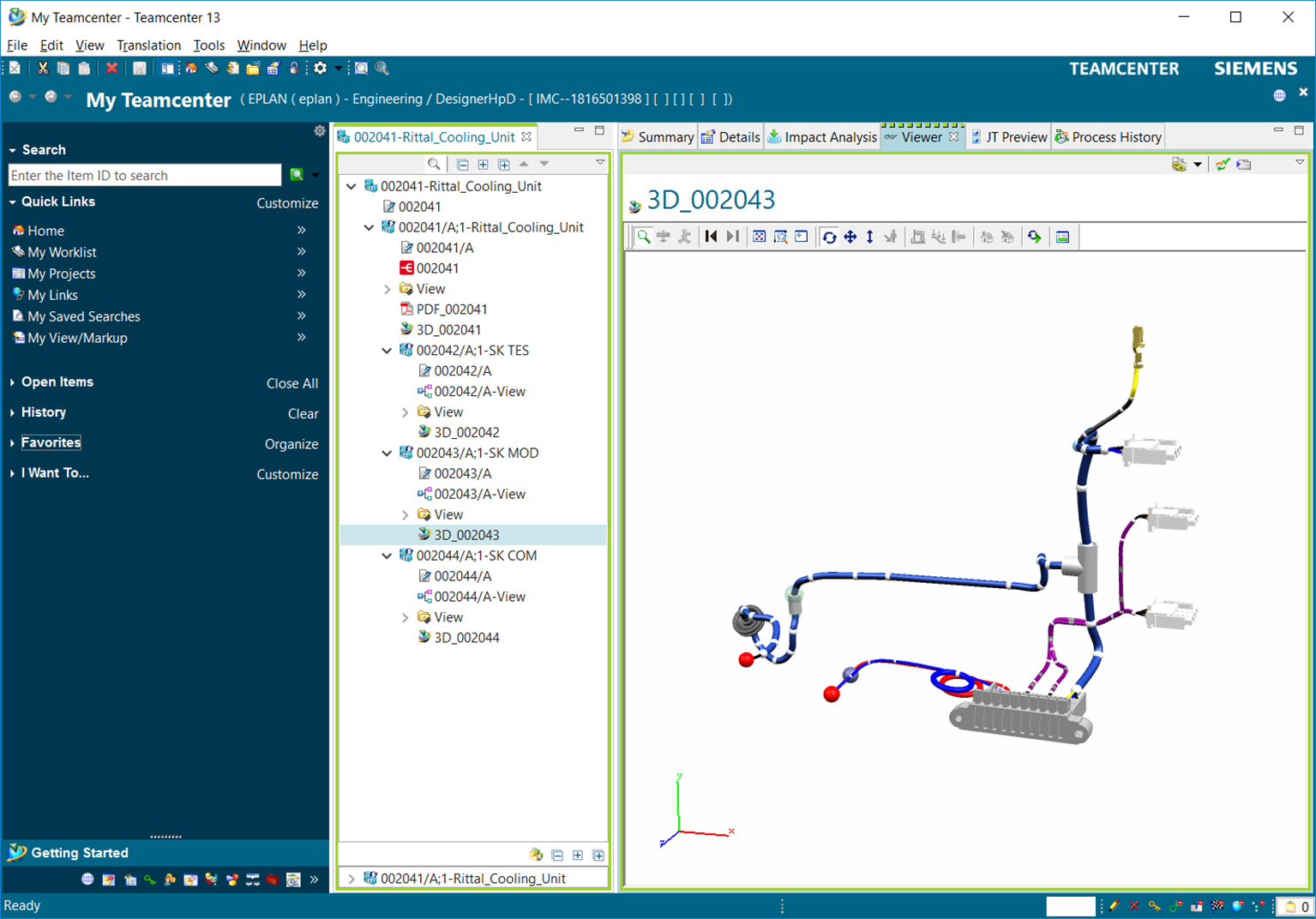

With the latest version of the Teamcenter Connector and the newly added compatibility of EPLAN Harness proD, EPLAN has closed a gap: for the first time, data from the cable and wire harness design can also be directly integrated. An extension that gives users new room for maneuver: 3D cable harnesses, cable harnesses and production drawings can be automatically and error-free transferred to Teamcenter or PTC Windchill. This means EPLAN users will save valuable time.

With the new version 2.4 of the Teamcenter Connector, 3D cable harnesses, cable sets and production drawings can now be transferred directly to PLM systems such as Teamcenter.

Integrated 3D cable information

The added value goes beyond engineering: Processes such as purchasing, production and maintenance are supplied with important 3D cable information through the enhanced performance of the EPLAN connectors. Arnd Paulfeuerborn, Head of the PLM Competence Center at EPLAN (pictured), explains: “Today it is essential that engineering data is also fed into downstream areas. With the new integration of Harness proD in Teamcenter and PTC Windchill, manual processes of field cabling are now being replaced by fully digitised processes. "

The benefit is also increased "by the increasing amount of cabling in the construction, also outside the control cabinet - especially in machine and plant construction", continues Paulfeuerborn.

Product data management requirements are covered

Standard integration means the integration of third-party applications using connectors directly into the EPLAN interface. This can also be seen as one of the most sustainable advantages of the automated system coupling, as compared to 'manual data exchange', users can conveniently access the respective PLM system from their familiar working environment. This promotes cooperation between the disciplines and ensures a consistent data workflow from engineering to maintenance.

The users receive specific support in the implementation of common activities in the field of product data management. This includes:

- design data management for EPLAN data

- opening, saving and revisioning

- support for the entire approval and change process

- creating and updating EPLAN evaluations

- synchronisation of project attributes

- adoption of naming and numbering rules

- generation, storage and revision of EPLAN parts lists in Teamcenter or PTC Windchill

- authentication of EPLAN users and assignment of rights in the PLM environment

You can find more information about EPLAN's standard integrations here.

Comments