Author

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

3D control cabinets & switchgear - Panel building for the future!

A valuable competitive advantage

"Control panel design is our forte", explains Min. "Our extensive experience of panel

types used across many industry sectors has given us the expertise to achieve results

that are optimally suited to customers' requirements. EPLAN Electric P8 and EPLAN Pro

Panel are the main tools we use and we decided from the onset to make EPLAN a key

business partner. The EPLAN licenses are, without a doubt, a major investment for us,

but we nevertheless see them as excellent value for money, not least because we know

that working with EPLAN software will give us a valuable competitive advantage."

"We collaborate closely with clients from the very beginning of the development phase,

through the whole project life-cycle, to the creation of complete automation concepts that

are cost and time effective" continued Min, "and EPLAN is at the core of this."

Automating time-consuming tasks

Since its introduction, EPLAN Electric P8 has become the market standard and its use is

frequently cited as a requirement by control panel specifiers. By using EPLAN Electric P8,

panel builders benefit from higher quality professional electrical documentation, which

thanks to the software's automated functions will further reduce time-consuming work.

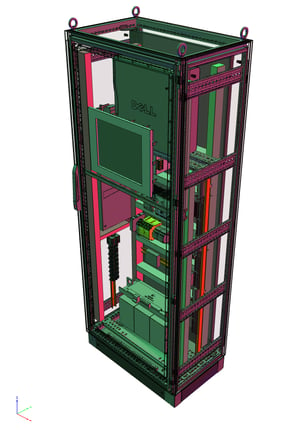

Complementing EPLAN Electric P8, EPLAN Pro Panel - an engineering solution for virtual

control cabinet engineering in 3D - which is also used by 81346 ELAB, enables

businesses to achieve savings of up to 75% on wiring time, as well as 50% in layout and

mounting time, leading to large increases in overall productivity.

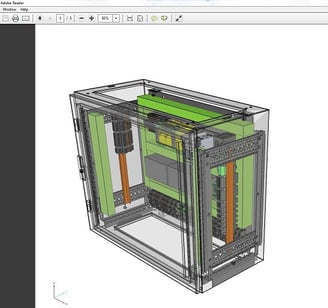

With EPLAN Pro Panel, engineers can design and construct three-dimensional control

cabinets and switchgear systems that are easy to review with the EPLAN software, or

they can be exported and viewed with Adobe Acrobat. This eliminates the errors that lead

to expensive rework. The software features include 3D mounting layout, virtual wiring capabilities, modification and adjustment of copper busbars.

Designed with flexibility in mind, EPLAN Pro Panel allows the user to choose their

preferred approach whether it is based on equipment lists or circuit diagrams. All

necessary components can be easily entered and positioned on the 3D layout, thanks to

the innovative eTouch technology.

Min finds that the virtual 3D model of the control cabinet switchgear system helps him

make best use of the valuable control panel space, and that integrated planning aids

such as collision testing, adherence to manufacturer installation guidelines, minimum

clearances and bending radii, allow quick and optimum positioning of components.

Making engineering practices more efficient

“Early involvement in the development stage of a project has positive impact on overall effectiveness", says Min. "At 81346 ELAB we believe that standards and directives, correctly applied, eliminate the necessity for time consuming and dare I say, soul crushing, minute-by-minute project management. It is important to get things right before you start your project, and EPLAN is ideal at helping with compliance and standardisation requirements".

EPLAN supports all customers in order for the company to become more efficient in their engineering. By making engineering practices more efficient, companies will gain a clear competitive advantage and one way of doing so is incorporating codes and standards into specific designs. EPLAN users can develop their own company-specific standards, based on optimal templates and the use of high quality design and master data.

The basis for reusability & standardisation

A key benefit for 81346 ELAB of using EPLAN is that it helps to create a consistent basis for reusability and standardisation. It offers correct settings and templates for the creation of cross-disciplinary schematics and lays down the fundamentals for future macro projects. Another major benefit is that high quality design for basic projects is guaranteed. The predefined master data and settings, the pre-set report templates make compliance easier and far less time consuming.

Complying with global standards

In addition, by incorporating codes and standards into their designs, 81346 ELAB complies with global standards for documentation and production, such as the new IEC

81346, IEC 61082 and IEC 61355, which help to satisfy the requirements applicable to documentation set out in IEC 60204 - a harmonised standard to the Machinery Directive.

The Machinery Directive (2006/42/EC) covers the supply of new machinery and other equipment including safety components. The law states that it is an offence to supply

machinery unless it complies with the Directive, so panel builders like 81346 ELAB must take this into account from the very beginning. The designer must be able to show evidence that proves conformity to the Directive and the best way to do it is to comply with the harmonised standards.

What the customer needed: EPLAN

81346 ELAB also routinely accesses the EPLAN Data Portal, which is a vast database of electrical, mechanical, fluidic and pneumatic components that is built into the EPLAN platform and provides online access to accurate and up-to-date device data for more than 1.2 million configuration variants of more than 600,000 devices from over 140 global manufacturers.

Graphical data can be downloaded from the portal as a package or as stand-alone information. This data can be dragged and dropped into EPLAN documentation and by adding the components to the project; this reduces the configuration work and increases the quality of the machine and system documentation.

"Using the EPLAN Data Portal in conjunction with EPLAN Electric P8 and EPLAN Pro Panel allows us to locate the components we need and pull the required information into our projects in an instant. This is much faster and more convenient than trying to create it from scratch, and also virtually eliminates the risk of errors. This means we can give the

best possible service to our customers, which is, of course, the key objective for our new business.

"EPLAN products are reliable and easy to use and we are very happy to have EPLAN as a partner right from the very start of our new venture. And, as an added benefit, EPLAN Software and Services are constantly evolving, which gives us the certainty that as our needs evolve, that EPLAN products will always evolve to meet them".

No matter what size your company or how many years you've been operating, request a free demo of the EPLAN solutions and disover your winning electrical engineering solution to boost efficiencies not only in the engineering department, but through the whole business.

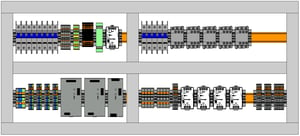

Do you also work in the panel building industry? Check out the new animation and  discover for yourself which EPLAN solutions can improve your processes; from sourcing and engineering, through to panel modification and wiring.

discover for yourself which EPLAN solutions can improve your processes; from sourcing and engineering, through to panel modification and wiring.

Click the image to view

Comments