Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

7 Benefits Of Using A Digital Twin

The prototype features all the physical and performance characteristics of physical object, including energy output and design flaws. This feature gives engineers crucial insight into component performance and real-world applications. Importantly, you can find this information without the costs and risks associated with prototyping.

Here are seven key benefits of using a digital twin in your design engineering process.

1) Better Research And Development

Virtual replicas enable thorough testing of an object under various scenarios to understand likely performance outcomes. The testing reveals any areas for improvement in greater detail than a standard 2D view could offer. Using digital replica as a 3D virtual prototype can therefore shorten the research and development cycle. This then facilitates better design decisions and continued improvements before an object enters physical production.

2) Enhanced Collaboration

Digital twins foster collaboration among team members by providing a shared platform for analysing. Engineers, designers, and stakeholders can access the same virtual model, allowing for real-time discussions and feedback.

This collective approach helps to align everyone’s understanding of the project, leading to more cohesive decision-making. As a result, teams can identify potential issues early on and address them before they escalate. This foresight will ultimately save time and resources.

3) Improved Customer Experience

Finally, digital twins can enhance the customer experience by providing insights into how products perform in real-world conditions. Companies can use this data to tailor their offerings to better meet customer needs and preferences.

For instance, by analysing how users interact with a product, businesses can make informed adjustments to design or functionality. Higher customer satisfaction encourages loyalty. Clients will feel that you value their feedback by guiding future iterations of the product.

4) Greater Efficiency

Digital twin engineering software can show physical objects and help with production processes and services. This software improves efficiency, allowing businesses to streamline their production and run at their best. Engineering managers can also collect data to show performance during real-world production. This helps identify areas where you can make cost savings and further optimise your manufacturing process.

The insights gained from digital twin technology can help businesses identify potential bottlenecks or flaws in their workflow. By allowing engineers to streamline operations and optimise resource allocation, you can keep budgets low yet effective. This proactive approach improves the quality of the final product and keeps projects on budget and on time.

5) Increased Reliability And Availability

Digital twins enables reliability and availability because of the 3D representation. Engineers can then pinpoint any potential issues without the expense of producing a physical prototype. Engineering teams can quickly make changes to the digital twin at a low cost,allowing them to improve products. This helps improve communication between departments on the project.

This helps improve efficiency during production and testing, and also helps to reduce faults later on. Some digital twin software can identify important airflow gaps in an electrical enclosure, helping to extend its lifecycle. This feature then reduces cost for any maintenance and servicing for manufacturers or suppliers.

6) Increased Customisability

Digital twin software enables companies to create highly detailed and accurate virtual representations of physical assets, processes, or systems. This capability allows businesses to simulate various scenarios and outcomes, providing them with the flexibility to adapt their offerings to meet specific customer requirements.

Customers can remotely configure their customised products using virtual models, saving your engineers time and shortening the approval cycle.

One of the key benefits of using digital twin technology is the enhanced level of personalisation it affords. Leveraging real-time data and analytics is a great way to gain insights into customer behaviour. You can then tailor your products and services accordingly!

This level of customisation helps you to meet the unique demands of each client. By doing so, a deeper connection between the business and its customers will form.

7) Predictive Maintenance

Another significant advantage of digital twins is their ability to predict maintenance needs. By consistently monitoring the performance of a physical object through its digital counterpart, engineers can identify patterns and anomalies that may indicate future failures.

This proactive approach allows for timely interventions, reducing downtime and maintenance costs. Instead of relying on scheduled maintenance, companies can adopt a more efficient strategy. By focusing on actual performance data, this guarantees that equipment operates at peak efficiency.

Summary

Integrating digital twin applications into the design engineering process offers numerous benefits. From better research and development to improved teamwork, predictive maintenance, and a better customer experience, these virtual models enable greater efficiency, accuracy, and innovation.

Digital twins simulate real-world conditions. They help businesses find design flaws early which reduces waste and improves production workflows. This not only saves time and resources but also enhances the outcome through product reliability and performance. As industries continue to adopt smart manufacturing and automation, leveraging digital twins will become essential.

Next Steps

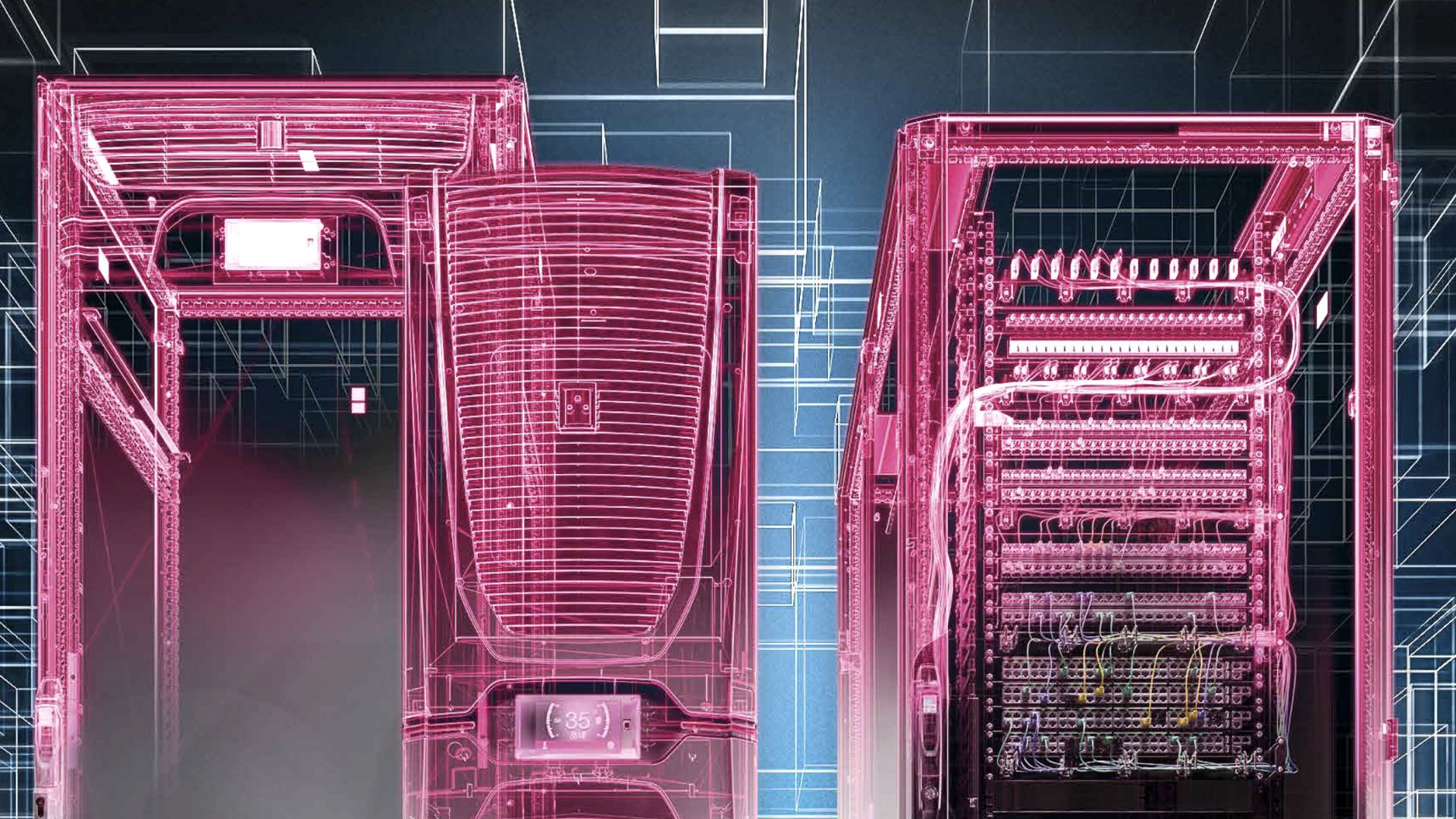

Eplan develops leading-edge digital twin software for both control cabinet design and wire harnesses. Our solutions bridge the gap between virtual planning and physical production, enabling seamless integration between design, engineering, and manufacturing. By adopting automation-driven processes, businesses can improve project timelines, minimise errors, and maintain compliance with industry standards.

These solutions offer automated wire routing and drilling information, ensuring greater precision and consistency across production cycles. With goals of improving engineering workflows or boosting product performance, digital twin technology offers a smart solution.

Comments