Author

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

Automation Concern Three – 'The benefits of automation in panel building are uncertain and limited'

So what’s going wrong? Why aren’t companies adopting automation? A key reason is that they are unaware of the many benefits that automation can bring to their sector.

Let’s start by saying that an investment into automation can reduce panel design and manufacturing by around 50%, a significant and tangible benefit, that is by no means unachievable. Just think of the extra projects your team could take on, leading to increased revenue and profits!

Digital engineering review process

And there’s more. Most benefits of automation in panel building stem from good CAE systems which feeds data into the whole value chain. The CAE system can be used to deliver documentation to the shop floor and commissioning engineers in digital format via a tablet or a laptop. This means everyone involved in the project will always have access to the latest and most accurate information whenever they need it. Shop floor and commissioning also have a return channel to send information to the design team about changes made in the factory and on site, ensuring the drawings and other documentation are kept up to date. This is referred to as having a single source of truth.

Benefit: One version of data is used throughout the whole value chain, minimising errors and a lengthy to and fro situation between departments.

The cloud-based solution, EPLAN eVIEW, allows for structured collaboration with co-workers, customers and service providers by letting you digitally implement engineering review processes. The software easily and intuitively leads you through the redlining process enabling you to view and comment on changes to a project. Discover more about how EPLAN eView makes collaboration and communication simple in the video below.

Use digital twins to automate design

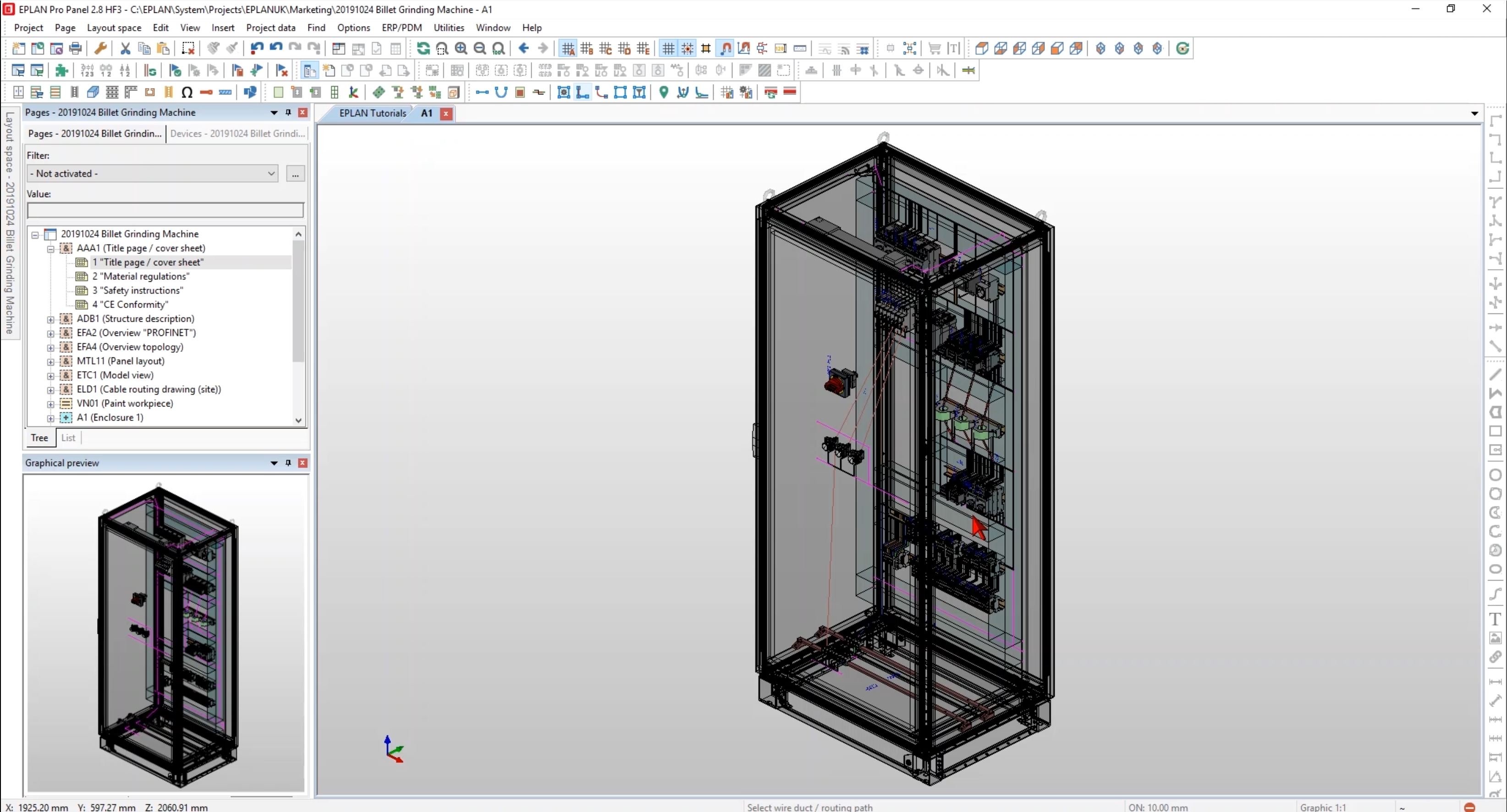

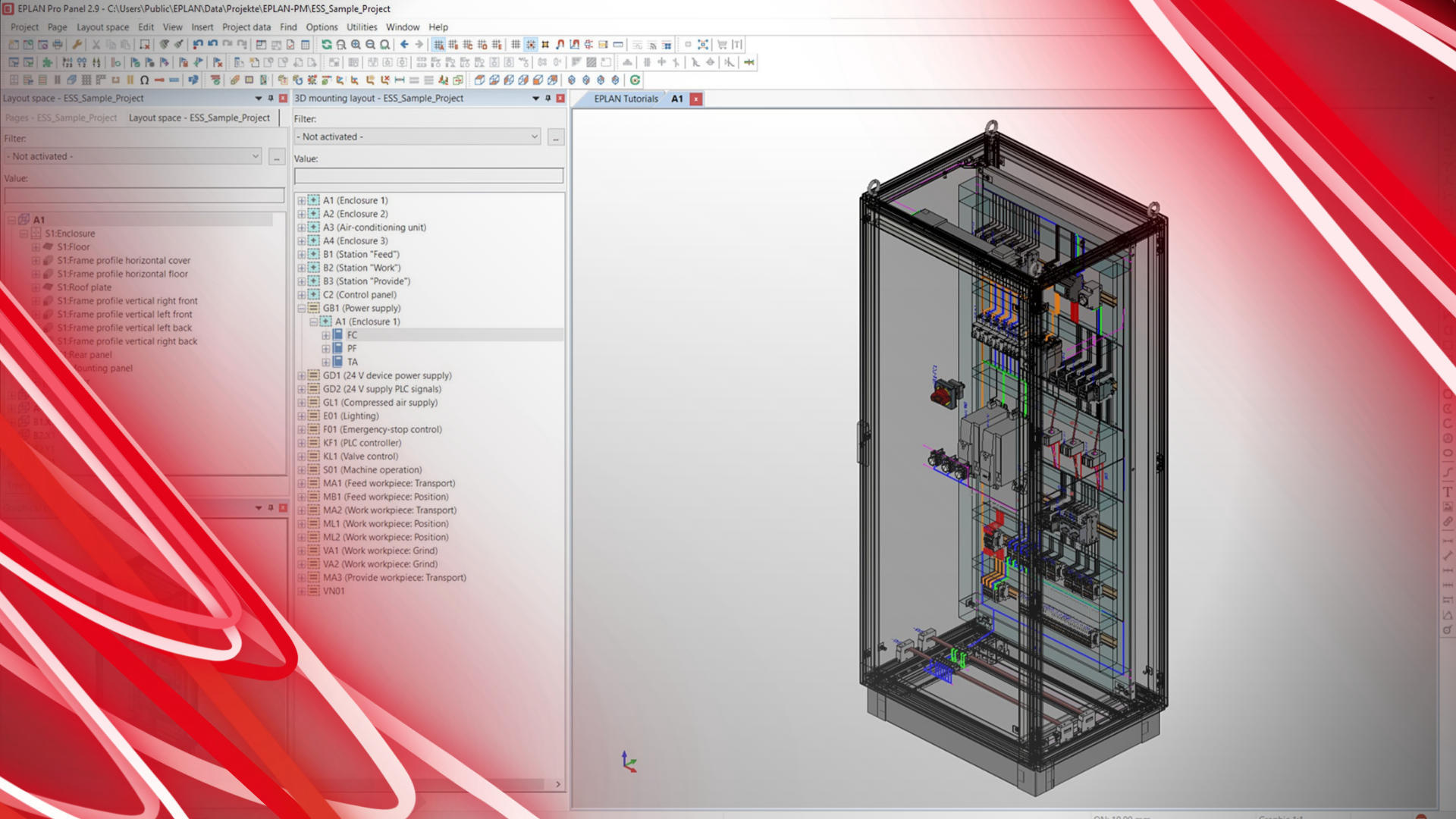

In fact, you could go a little further and use the advanced facilities provided by the latest CAE systems to generate “digital twins” for your control panels. These are, in effect, virtual prototypes of the panel which can be examined before work starts on building the real thing. The digital twin can be submitted to the customer for approval in the design stage and changes can easily be fixed (usually with a few mouse clicks) without the high costs, extensive reworking and possible waste of materials. A change of position of a component can be written back to the schematic and a new wiring list is generated.

The digital twins also allow the CAE system to automatically determine the routing of the wiring and present a wiring list for the technician. This removes the need for complicated diagrams by where the wire person must interpret where the components are placed to fit in the control cabinet. EPLAN Smart Wiring is your virtual assistant for manual wiring in panel building. From the connection point to the exact wire routing, the software provides the wiring technician all the necessary information in digital form – also in 3D when required.

The digital twins also allow the CAE system to automatically determine the routing of the wiring and present a wiring list for the technician. This removes the need for complicated diagrams by where the wire person must interpret where the components are placed to fit in the control cabinet. EPLAN Smart Wiring is your virtual assistant for manual wiring in panel building. From the connection point to the exact wire routing, the software provides the wiring technician all the necessary information in digital form – also in 3D when required.

Benefit: Using a 3D digital twin makes it easier to identify necessary changes in the design stage to reduce high costs, extensive reworking and the waste of materials.

Make 2021 your year for Automation! The key is to make a change, however small, or risk falling further behind competitors. Download the free whitepaper ‘The Year of Automation?’ and discover more reasons why you should be automating your panel building, especially in uncertain times.

Comments