BIM in Building Automation - The Right Connection Is Everything

Today, successful engineering requires collaboration. From solution provider EPLAN’s point of view, building information modelling (BIM) offers an effective way to meet the modern challenges in construction. At the centre of this integrated, model-based process is a cross-trade 3D building model that serves as the single source of information, one that is constantly being enriched with data over the course of a project. Standardised data structures and element descriptions form the foundation for creating the closest possible integration into existing IT infrastructures and processes. Only in this way can all project stakeholders and participants jointly benefit from using the BIM method. EPLAN offers the know-how and the corresponding solutions – after all, numerous customers in the field of building technology are already taking full advantage of the integrated EPLAN Platform, which is also used in industrial automation.

“The BIM method does not make planning more expensive. It makes them more efficient and therefore more cost-effective if they are introduced well and used correctly, ”explains Rolf Schulte, Vertical Market Manager Building Technologies at EPLAN.

BIM in Building Automation

Where does EPLAN see the greatest added value in using the BIM method in the area of building automation? Collision detection between architecture-specific, load-bearing and technical building services elements helps prevent unpleasant surprises at the construction site. To achieve this, information about building automation components as well as from other disciplines is added to the model depending on the stage of the project. This allows an exact status quo to be determined at any point in the project life cycle. One might ask what information the BIM model contains with respect to the electrotechnology. The answer is simple: for one, it includes the traditional installation technology – switches, sockets, lights, cable ducts, etc. In this context, the routing paths and cut-outs can be modelled. Furthermore, information for building automation is also included. Everything can then be evaluated, analysed and made available for other software programs in an integrated manner.

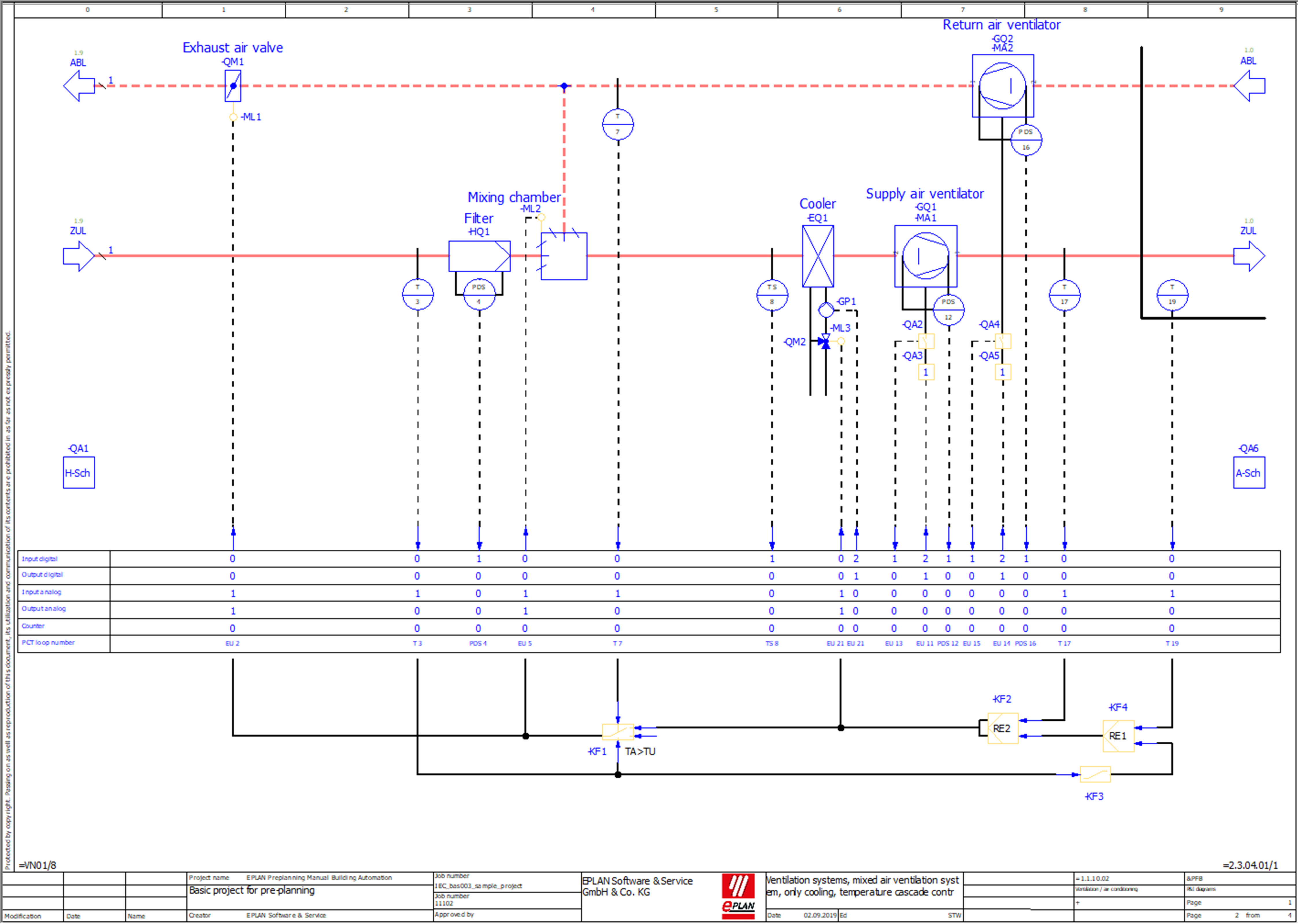

Control scheme: ventilation systems, mixed air ventilation system, cooling only, temperature cascade control

Adding/Managing Parameters

There is often scepticism that too many parameters must be entered at a far-too-early stage of the project using the BIM method. While this scepticism isn’t entirely unfounded, EPLAN finds that it depends on the process – on how the designer handles the supplying of information to the BIM model. If we take a look at the process of building services designers, numerous functions and components, regardless of manufacturer, are available as a standard within the various BIM authoring solutions for the trades of heating, ventilation, climate controls, plumbing and electrical. These components are used in early planning phases. As the project progresses, additional information is added to the components individually or via collective revisions depending on the project phase. Some BIM authoring solutions offer tools or apps to intuitively and more easily manage the parameters in the project by means of a database. In this way the information about the parameters can be added to the BIM model in a way that conforms with the HOAI – a German law regulating fees for architects and engineers, to name just one example. Data is thus input or enriched exactly when and how it needs to be provided and in the detail required during each phase of the project.

Communication Is Everything

As EPLAN sees it, BIM functions as a facilitator, combining different solutions for individual requirements in the best possible way. After all, building automation includes floor plans, heating capacity calculations, energy-saving requirements, diagrams and also schematics for the electrical installations. Where does BIM start and where does it end? BIM is primarily used in the context of a 3D model in structural engineering, in building automation or for structural analysis. The 3D model is thereby a single source of truth. However, this doesn’t mean that all the information must be generated from within the model. For instance, the BIM model delivers information for calculating the heating load through the building’s structure and spaces. Yet the designer doesn’t perform the calculation in the model, but in a program designed for that purpose. Afterwards the calculated values can be input back into the model. The same thing applies for the heating pipe calculations, volume flow and others. Each software has its own special field of application. The better each of these softwares communicates with the 3D model, the better the workflow efficiency.

BIM: Data Synchronisation Between Systems

EPLAN Platform has all the corresponding connections at the ready. A practical example: the BIM model contains valuable information about the structure of the property, including the building and, for example, down to the entire interconnected heating systems – from the boiler to the radiator. EPLAN uses this information to map the structure and to provide components. The parameters are then correlated with the BIM model. If something is changed in the structure of the model, or if components are added to the system, these become visible via data reconciliation. The designer can then decide how these changes should take effect within EPLAN Platform. Furthermore, data that has been enriched in EPLAN Platform can naturally also be written back into the BIM model.

Conclusion

Cooperation and collaboration in the field of BIM are indispensable. EPLAN contributes its expert knowledge for generating schematics for building automation and control cabinet engineering. Together, the providers combine their expertise and thereby offer designers in the field of building automation the greatest possible benefits for highly efficient processes.

Comments