Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Can you do Functional Design?

A good drawing has the correct information for all of the professionals concerned. The panel builder prefers to work with a cable and termination lists. The service technician prefers to see everything in one schematic so that he can quickly locate the malfunction. It isn't just about the correct information, but how it is presented.

Functional Basics Video

An Overview Report

Every professional needs their own 'view' of the project. As an electrical engineer, you have the challenge of providing everyone with the correct information and layout, whilst also drawing your own schematics quickly. How do you please everyone and go home on time?

To generate all of the different views, you need an overall report. One way of creating an overall report is a functional-orientated drawing.

The Difference to Production-Orientated Drawing

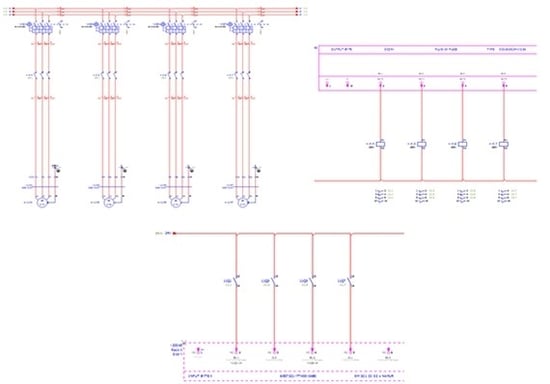

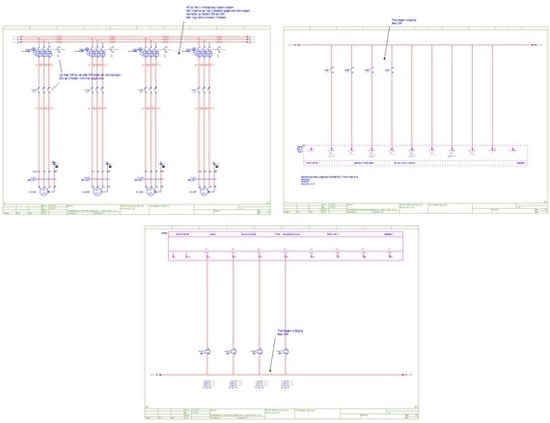

Traditionally, we draw in production-orientated methods: a sheet for the arrangement, management and report. So at least three sheets.

Traditional drawing: every component on its own sheet

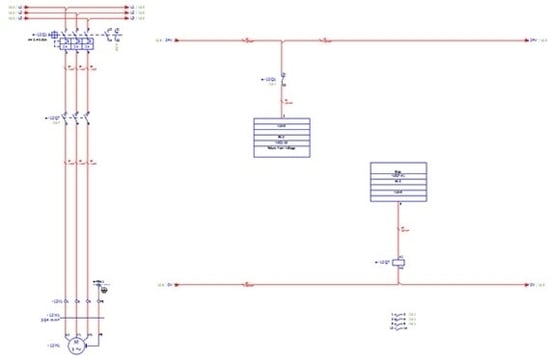

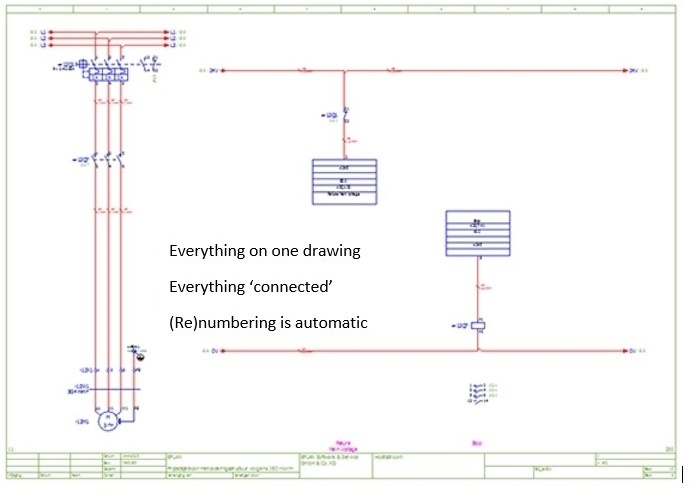

If we draw in a functional-orientated method, we can look at what belongs together functionally, and draw this on the same page; schematic arrangement, documentation and reports together. We draw one sheet instead of three, which saves time per unit. Therefore, functional-orientated drawing helps you to produce schematics faster.

Functional drawing: all components on one page

Functional drawing: all components on one page

Functional Drawing: all components on one page

In the functional drawing how-to video, the conveyor belt's design is used as an example to show what a difference it makes in comparison to traditional drawing methods.

75% Faster Creation and Modifications

Every design undergoes at least several modifications. You benefit from the functional drawing methods during modifications. Take the conveyor belt as an example. Say that we insert an extra conveyor belt. In the previous working method, you had to insert and move at least three sheets, namely, the drive circuit, the PLC input for your monitoring circuits and the PLC outputs for the contractors.

Inserting in the traditional method.

Inserting in the traditional method.

With functional drawing, you add the extra function to one sheet.

Inserting in the functional method

Inserting in the functional method

The Difference Video

Simple Control, Flexible Design

Functional-orientated drawings have many more advantages:

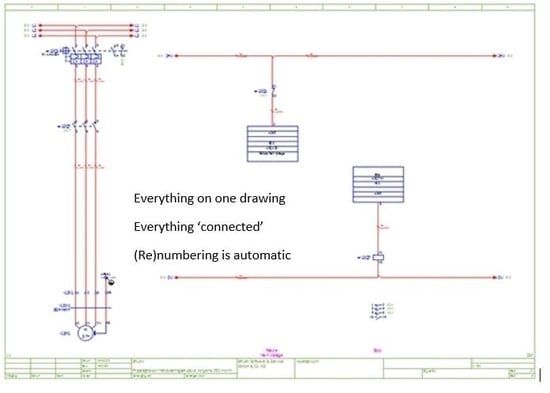

- The drawings are easier to control because everything is on one sheet

- The design can be tested in advance to ensure that all teething problems are removed. This is important because rectifying an error later in the drawing part of the engineering process costs ten times more in time. It costs even more time to make these adjustments in the workshop or on site with the customer.

- In addition, we can issue approved parts of the installation to other disciplines such as software programming. Functional-orientated drawings therefore make the design process more flexible.

- The engineering program allows you to automatically route the wiring both according to its positioning on the assembly plate an in the shortest way.

Everyone's Own Overview

Different drawing method, different mind-set. At first glance, you may be confused by this drawing method. What information do you need to construct panels? Is the schematic really necessary?

Each to their Own Video

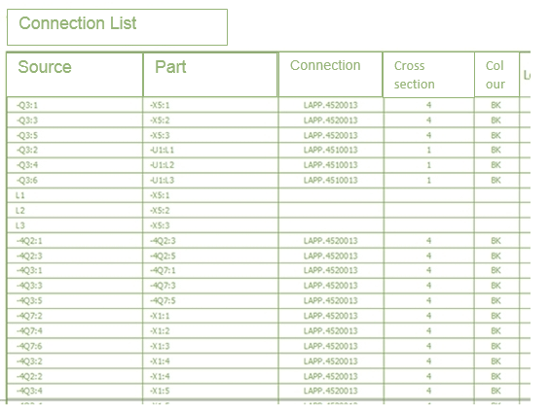

The workshop only needs three views: a panel arrangement drawing, a wiring list and a parts list.

Instead of sending the schematics to the workshop, the design software - EPLAN - generates them and the cable and termination reports for the panel builder. This happens at the push of a button and is based on the functional drawing. The same happens for the assembly documentation and the service personnel.

Lists are automatically generated by the engineering software

Lists are automatically generated by the engineering software

Comments