Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

How to Correctly Import Components into Parts Management

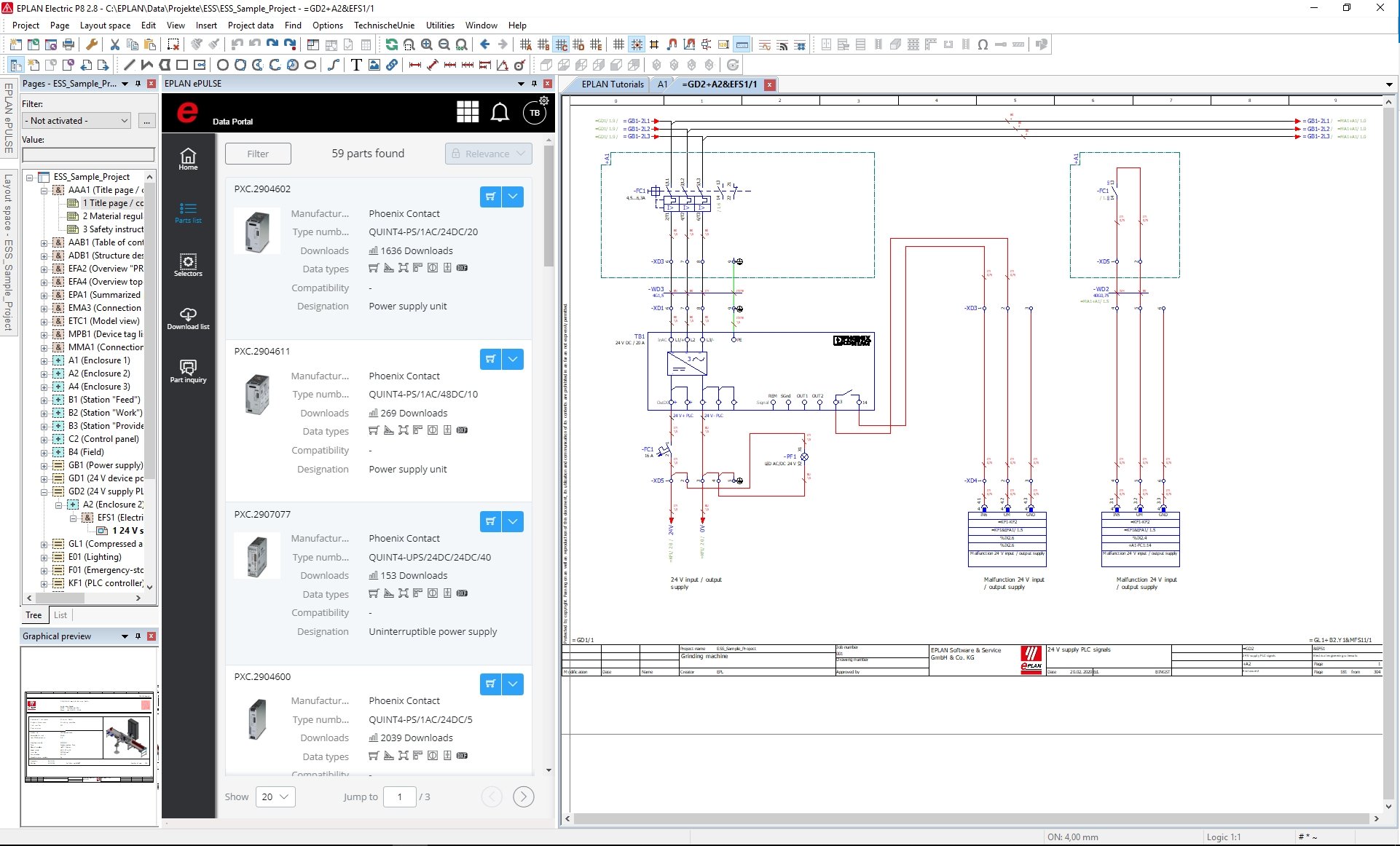

If you want to work smarter with EPLAN, the EPLAN Data Portal is a must. This portal contains the most up-to-date component data from hundreds of suppliers. Just think of function templates, macros, mounting data, technical characteristics, and even 3D models. In order to select parts from the EPLAN Data Portal, it is helpful to first load them into the parts management in your own EPLAN environment. We will explain below what you should pay attention to.

Control your Tree Structure

When you import a component from the EPLAN Data Portal into the parts management, make sure that you do not lose your advantage with the download default path. Imagine that you have worked out a whole tree structure in your macro folder with sections such as protection, relays or switches. When you import a component from the EPLAN Data Portal into the parts management, EPLAN always places this data in a fixed location within EPLAN. This can cause the carefully constructed structure of your macro folder to become cluttered.

Work with a Test Directory

To avoid this, use a test directory when importing components (set a scheme in the settings for the EPLAN paths). By doing this, you can easily adapt the description of the component and avoid the EPLAN Data Portal default paths entering your tree structure. As soon as you download a component via the EPLAN Data Portal, the component is not imported into the live existing tree structure but instead into the test environment. This way, you retain control over the import and your existing tree structure is safely stored.

Avoid Low Quality Component Lists

Suppose you are sent a component list that the customer requests you to use in the project. It often happens that this component list contains poor component data: macros or other technical data may be missing, for example. To boost your efficiency, aim to enrich these components with additional information. There are services available where the EPLAN experts can upload lists to speed up the implementation process.

Protect Existing Fields

If you have already created a macro or entered customised descriptions for a particular component, ensure that you do not overwrite the macro or description you have created. It is a good idea to secure the "macro" or “designation” field during the part import so that you only import the missing data from the EPLAN Data Portal and your custom macro remains unchanged.

External Editing of Components

If you need to adjust an ERP number or a description for multiple components, you can streamline the process by exporting the desired data via parts management and modifying it in Microsoft Excel. The most efficient approach is to use a comma separated values file (CSV) in Excel format for this task.

To minimise unnecessary data, only export the relevant fields, such as the ERP number, by modifying the configuration file. Once exported, you can then enrich the data in Excel. After making your changes, save the file as a CSV in Excel format and upload the components back to your parts management system. EPLAN will then incorporate the updated data automatically. Handy, right?

Are you more of a visual learner? Check out how to import parts from the EPLAN Data Portal in this short video.

Find more expert tips and tricks for efficient designing within the EPLAN software here.

Comments