Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Crossroads: digitalisation, environmental responsibility and profit

Two years ago, only 35% of executives listed ‘positive impact on society’ as one of their main corporate goals, but now, according to the study, the number has almost doubled. This change in opinion, which some have dubbed ‘the Greta Thunberg effect’, reflects the seismic shift being felt at every level of society.

However, businesses say that generating revenue is the top reason for focusing on societal issues (42%), followed by pressure from external stakeholders (39%) and pressure from employees (22%). So how can today’s businesses uphold their environmental and sustainability credentials whilst at the same time generating the profits and results that shareholders demand?

Responsibility and profitability

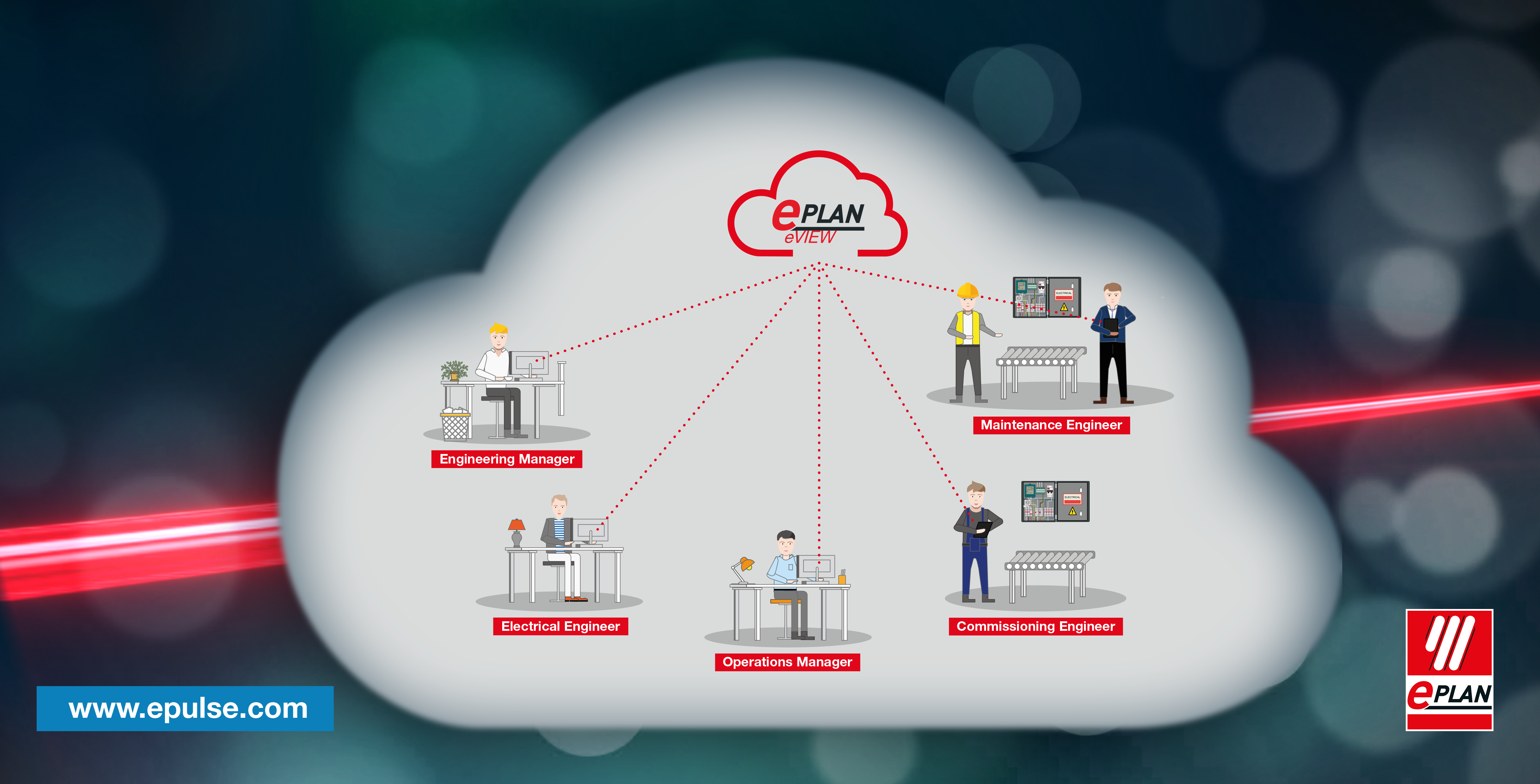

At EPLAN we firmly believe that corporate social responsibility and profitability are not mutually exclusive. With tools such as EPLAN eVIEW - a free cloud-based solution that enables users to easily and efficiently implement engineering review processes of schematics and remote project collaboration between electrical engineers, maintenance engineers, operations managers, commissioning engineers and even business partners - users can support sustainability practices.

The digital revolution makes possible greater efficiencies and faster communications between departments, while at the same time greatly decreasing the carbon footprint of businesses. With it, everyone who needs access to up-to-date project information can access it without the need to travel or to print documents.

In terms of economic benefits, the new digital platforms facilitate knowledge-sharing and enhance learning opportunities. For example, cloud-based engineering, as typified by EPLAN eVIEW and EPLAN eBUILD, bridges a key knowledge gap for many panel builders and helps them to move their 2D models into 3D space so that they can enjoy the many benefits, economies and profit opportunities that results from working with digital twins.

Going paperless

Another aspect is the paperless business. This concept has been around for decades, but it is at last turning into reality – for the manufacturing sector, at least – with the advent of end-to-end digital design and engineering solutions. Keeping crucial data on pieces of paper may seem easier to begin with, but although the data might be (almost!) correct to start with, it certainly will not be updated in real time and hence by the time the product or project is delivered ‘the paperwork’ is almost certain to contain numerous inaccuracies and maybe an uncontrolled version.

EPLAN systems promote the use of interactive paperless work instructions in the form of smart Adobe Acrobat (.pdf) documents that support feedback via comments. What’s more, for those who are on the go, the paperless documents can be accessed on handheld devices like tablets, so they can go about their job untethered to a PC and unencumbered by a bagful of drawings and paper documents. Alternatively, redlining and greenlining can be completed with eVIEW, and via the cloud, the schematic project is kept up to date to ensure a single source of truth for all defined project users.

Further benefits are that quality and regulatory audits can be done digitally via a single system, with revision control and document management information visible to all those concerned. Such audits can even be done remotely, and in appropriate circumstances this significantly reduces the associated costs not only for the manufacturer but also for the customer.

Reducing energy consumption – a case study

When it comes to protecting the environment, using less energy and consuming fewer resources are reliable ways of reducing environmental impact. Software tools such as Rittal Ri-therm which integrates with EPLAN, are enormously helpful in achieving these objectives. They take care of the complex calculation of climate control requirements and guide users toward the most suitable climate control solution.

In an industrial environment, cooling enclosures and spindles typically accounts for more than 15 per cent of the total energy consumption of machine tools. A recent test installation on a CNC lathe at Bosch Rexroth demonstrated how the new Rittal Blue e+ chillers significantly reduce this energy consumption.

Following retrofitting of the lathe, the cooling medium is provided via a Rittal Blue e+ Chiller, which incorporates an energy-efficient inverter-controlled compressor. This arrangement has reduced the amount of energy used by the cooling system to less than half of that previously required. The cooling units for the lathe control panel have also been upgraded and, in this case, energy savings of no less than 80% have been achieved.

The trial also highlighted how easy the Blue e+ is to operate. The Blue e+ App communicates with the cooling units via NFC (Near Field Communication, an international transmission standard based on RFID technology for contactless data exchange), allowing important information to be transmitted wirelessly; a functionality which is especially important when a number of chillers have been configured. It allows operators easy operational oversight and facilitates a swift response, if required.

What does the future hold for eco-driven companies?

By adopting practical strategies for environmentally friendly manufacturing, engineering companies can help promote a sustainable future. Making effective use of digital technology is the key, and employing the practical money, energy and time-saving tools provided by EPLAN and Rittal is a sure way of helping you to meet your environmental responsibility objectives without impacting your bottom line.

To get free access to eVIEW register for your free account at epulse.com

Comments