Author

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Develop a Common Engineering Platform

A more efficient engineering process starts with choosing standardised, functional components. You can read about this in our previous blog ‘how can you engineer quicker?'. The next step is to save these standardised components in one common engineering platform.

Functional Platform

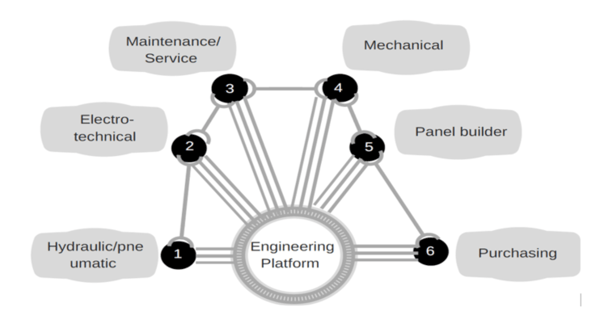

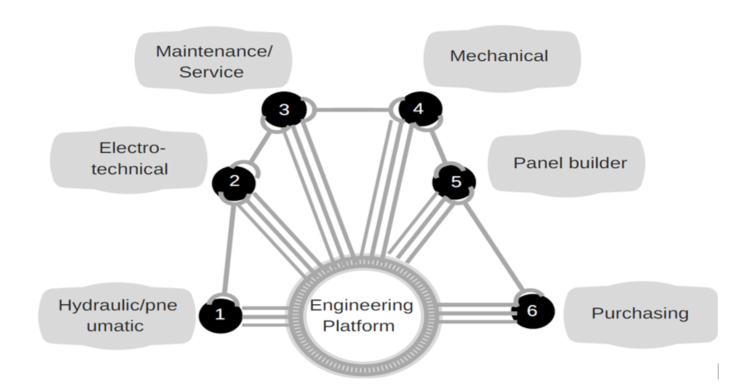

Every discipline has its own user interface. The user interface focuses on the specific tasks per discipline but stores everything in one platform. All of the components’ data is stored centrally in the engineering platform and can be accessed by any engineer. If an engineer adds or changes something in the components’ design, these changes are automatically updated in all of the other disciplines.

What does a central, functional engineering platform look like?

What does a central, functional engineering platform look like?

A common engineering platform allows complete transparency between the different business stages. The electrical, pneumatic and hydraulic schematics can be further developed from an overview drawing or P&ID (process and instrumentation drawing). Common information is displayed automatically in the relevant schematics.

Both standardisation itself and capturing it in a common engineering platform has an important advantage: all of the information is saved once in one place. Additionally, this method can help to prevent mistakes by, for example, making the changes or automatically reporting the conflicting or missing parts.

Everything Digital

For this platform to function, all information (everything from the component database to schematics and item lists) needs to be digitalised, saved, shared and connected centrally. This needs to not only be within engineering and production, but also within other organisational units, like purchasing and product documentation.

Having a good component database is an indispensable link in a central engineering platform. Luckily, the leading component manufacturers deliver extensive product and component information. This product information should include both logistic information and the relevant engineering information, like the schematic display of the product or component, functional & physical specifications and graphic macros & datasheets. This information must firstly be available via an internet connection and secondly be in the engineering platform. Thirdly, it also needs to be able to be imported into its own standardisation.

Live Connection with PLM and PDM

After digitalisation, there is an integration with PLM (the Product Lifecycle Management system) – this consists of the ERP (Enterprise Resource Management) and the PDM (Product Data Management system) – an absolute must for a successful engineering platform. This includes, among other things, both a transparent throughput of the material requirements from the project to purchasing, and capturing the different project versions by managing these versions appropriately.

A common engineering platform makes a transparent collaboration between the different engineering disciplines, purchasing and sales possible. How can we establish a seamless collaboration with production? Stay tuned to find out!

Comments