Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

EPLAN Smart Mounting: Easy control cabinet assembly solution

Time pressure, a lack of skilled workers and poor communication are common challenges every day in control cabinet manufacturing. The new EPLAN Smart Mounting software mitigates these factors and supports manual control cabinet assembly with maximum efficiency. Step-by-step, the new solution guides the technician through the assembly of rails, cable ducts and electrical components, showing which component is to be placed where. Through 3D visualisation, even less experienced specialists can see where and how each component has to be placed. When combined with EPLAN Smart Wiring, cabling can also be precisely displayed in the same format.

Improved communication between engineering and production

The digital twin in EPLAN Pro Panel provides the relevant engineering information for control cabinet manufacturing - for example dimensions, positioning, drill holes and the type of fastening of the components can be displayed. Technicians can store comments on components directly in EPLAN Smart Mounting and send them back to the engineering department. This means that documentation is always up-to-date, improving communication across departments.

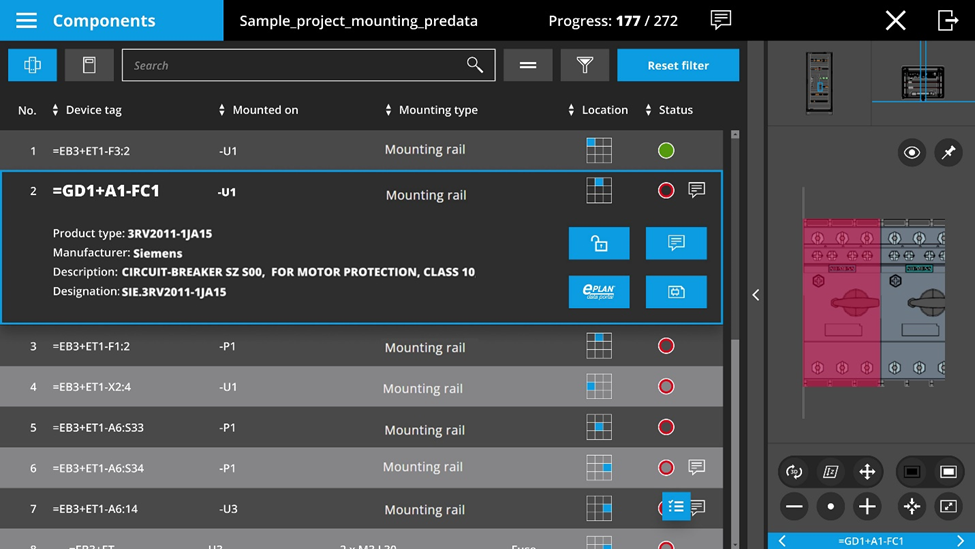

EPLAN Smart Mounting accelerates the population of components in control cabinet construction. The software shows the technician where each component has to be placed.

EPLAN Smart Mounting accelerates the population of components in control cabinet construction. The software shows the technician where each component has to be placed.

Project changes during assembly? No problem.

Another practical advantage is that changes to the project can now be quickly implemented. For instance, if there have been changes to the customer specification and an additional motor circuit breaker or contactor is to be added, this can easily be updated and added to to the new project. The software shows precisely where components must be removed or which need to be added. This means tedious manual document comparisons no longer need to be done, saving time, and ensuring correct results. And if questions should still arise, EPLAN Smart Mounting provides direct access to the interactive schematics.

Better overview and more flexibility for production managers

It isn’t only workers on the shop floor who gain full support. Production managers also get a better overview and more flexibility – they can see the status of open production orders at a glance. A control system displays the assembly progress for each component: green means completed, while red means not yet processed. If there are resource bottlenecks or downtimes, an order that has already been started can easily be handed off to another employee. In addition, personnel resources can be utilised more flexibly for different production steps.

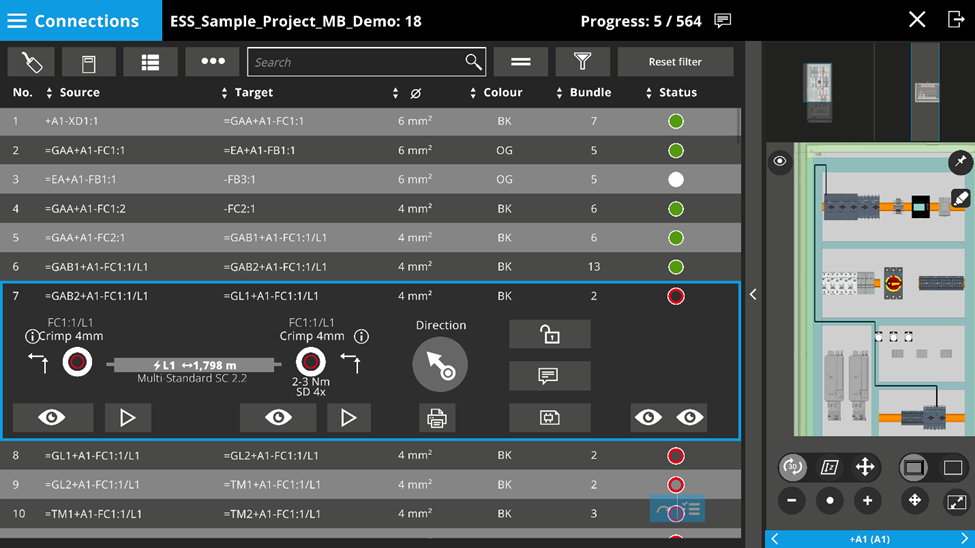

Great interaction between assembly and cabling

This isn’t yet the end of the process. The data foundation from EPLAN Pro Panel can also be used for cabling. Using EPLAN Smart Wiring means the complete downstream wiring process for the control cabinet can also be system-based. A uniform interface for EPLAN Smart Mounting and EPLAN Smart Wiring, as well as the digital twin from EPLAN Pro Panel as the single source of truth, ensure maximum end-to-end data consistency. The software is naturally compatible with fully automatic wire assembly machine such as the Rittal Wire Terminal WT, and prefabricated wires can also be used. The aim is to achieve the highest degree of automation possible from the initial engineering phase to manufacturing while at the same time ensuring maximum quality.

With EPLAN Smart Wiring, the wiring process can also be supported system-guided in the same way.

With EPLAN Smart Wiring, the wiring process can also be supported system-guided in the same way.

A question for Tobias Kratz, Business Owner:

Last-minute project changes are common in control cabinet manufacturing. How does EPLAN Smart Mounting relieve these issues in engineering and production?

"If customer requirements change or components are not available, the production order can be updated with the new project status on the central server. This means everyone involved in the project receives the updated version. The real added value, however, comes from the support of the technician. He no longer needs a version 1 and version 2. The technician assembling the panel receives an updated checklist in which he can see which components have to be additionally mounted, which have to be disassembled and which have to be changed. The Smart Mounting software not only takes into account the difference between the two versions, but also includes the current assembly status, so the technician is guided through the change - again step-by-step with visual support."

You can find this and more information about EPLAN Smart Mounting on our website.

Comments