Author

Barry Chatham

Barry is a Business Consultant for EPLAN UK, working closely with the commercial team and a facilitator to the technical team in ensuring that EPLAN are delivering the right value at the right time to our customers.

Having graduated as an Industrial Designer and being deeply immersed in a wide range of disciplines, the learning curve in each of Barry's roles has been vast. This brings with it a wealth of experience, something demonstrable from recent years in CAD software such as Siemens PLM and more recently SolidWorks, where starting in technical and moving into commercial roles, Barry has successfully assisted hundreds of companies through transitional change and added value not only to his customers but heavily focusing on their customers and delivering results in dozens of different industries.

Having been asked the question years ago at an interview, it changed his outlook and discussions on the manufacturing industry, the question was "I make scissors in Sheffield as a consultant, I want you to make me more money"...

This question, and the "so what" methodology enabled Barry to see from a different perspective, something which is proving to be very well received with some of our customers already.

Chatham.b@eplan.co.uk

Barry Chatham auf LinkedIn

Barry Chatham

Barry is a Business Consultant for EPLAN UK, working closely with the commercial team and a facilitator to the technical team in ensuring that EPLAN are delivering the right value at the right time to our customers.

Having graduated as an Industrial Designer and being deeply immersed in a wide range of disciplines, the learning curve in each of Barry's roles has been vast. This brings with it a wealth of experience, something demonstrable from recent years in CAD software such as Siemens PLM and more recently SolidWorks, where starting in technical and moving into commercial roles, Barry has successfully assisted hundreds of companies through transitional change and added value not only to his customers but heavily focusing on their customers and delivering results in dozens of different industries.

Having been asked the question years ago at an interview, it changed his outlook and discussions on the manufacturing industry, the question was "I make scissors in Sheffield as a consultant, I want you to make me more money"...

This question, and the "so what" methodology enabled Barry to see from a different perspective, something which is proving to be very well received with some of our customers already.

Chatham.b@eplan.co.uk

Barry Chatham auf LinkedIn

EEC Forum becomes EF|A 2021 - EPLAN Forum for Automated Engineering

What awaits participants at the global online event? The successful EEC Forum becomes the online conference EF|A 2021. The range of presentations and speakers has been expanded to include topics of modularisation and product structuring, as well as standardisation.

For standardised engineering, it is crucial that modularisation is well thought out in advance right through to the end. For example, how is the functional structuring of a machine-implemented with corresponding options, variants, features and dependencies? These questions should already be answered when planning a machine/plant. With EF|A 2021, Eplan would like to support companies in getting down to business and illustrate the low-threshold approach to implementing a product configuration and further steps.

In addition to Eplan Engineering Configuration(EEC), Eplan Cogineer and Eplan eBUILD have now established themselves as professional tools for solutions in automated engineering. Experience shows that companies with an existing product structuring system are involved in professional machine cabling. For this reason, the Eplan solution Harness proD for machine cabling and cable harness engineering will also be presented and discussed in detail.

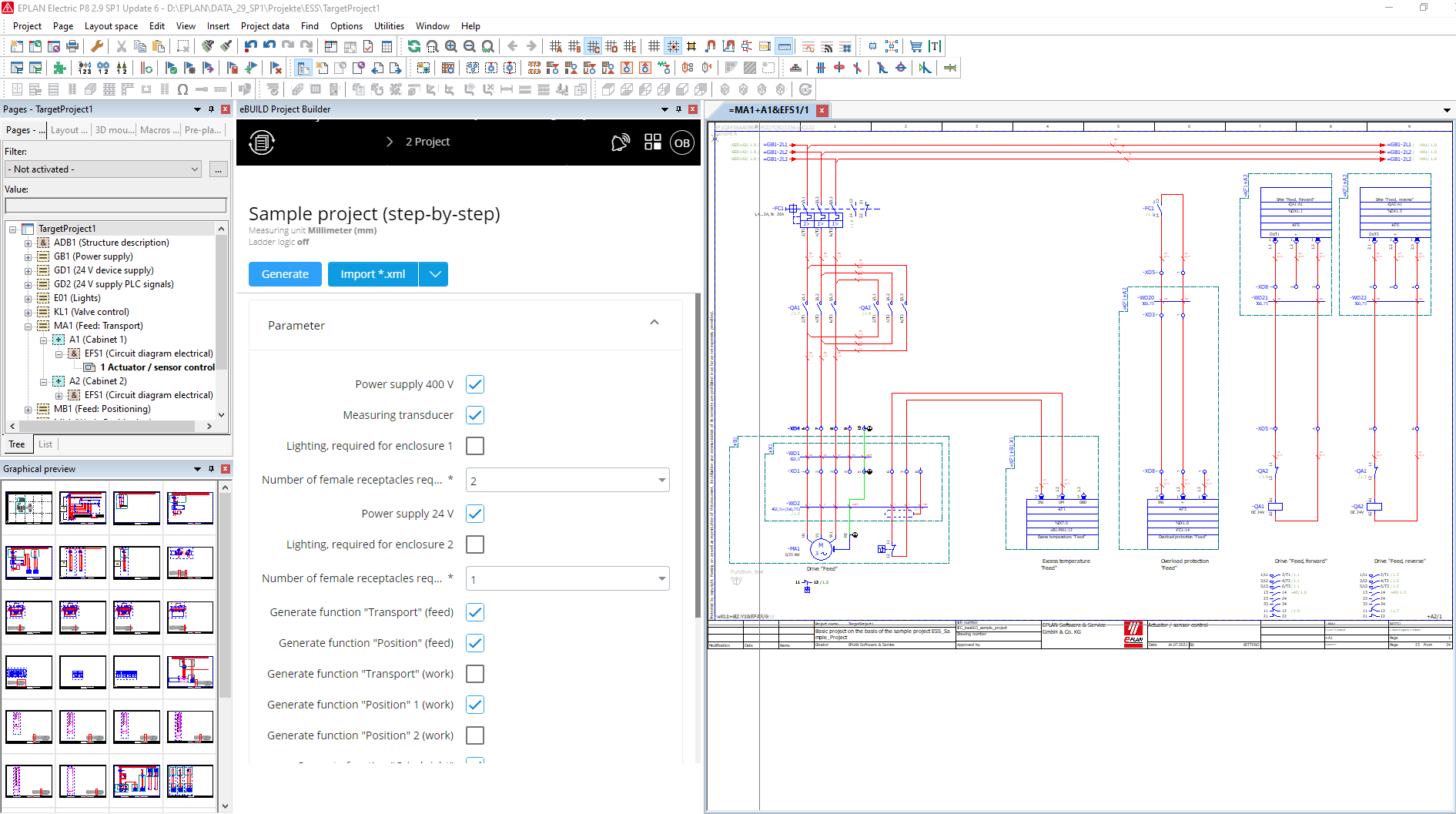

Eplan eBUILD in EPLAN Electric p8 version 2.9

Eplan eBUILD in EPLAN Electric p8 version 2.9

Immersion in various workflows around products and machines with series character

The virtual journey through EF|A 2021 begins with live talks, lectures and customer presentations by the speakers. International Eplan customers such as Aggreko, BST, Danfoss, KHS, Oskar Frech, Scheuch and Spiromatic will take interested visitors on a tour of their tried-and-tested solutions and show the background to their strategies and implementations. From these presentations, visitors will gain first hand insights and best practices. The strategies and innovative solutions presented will highlight that the effort to implement automated engineering is worthwhile and that it is more realistic than initially assumed. It’s an effort that pays off, as a machine that has been modularised from the ground up ensures significantly more efficient processes from design to production.

How to - The presentations in the Dive-in Area will address the following topics:

1. Structuring machine/product from a functional perspective

The basis for many optimisation steps in design and manufacturing is the modularisation of the product. Here, visitors will gain first insights into how to implement functional structuring and define options, variants, features and dependencies.

2. Creating macros and template projects in Eplan

The basis for automated engineering with Eplan is precisely fitting templates. Learn how to easily create templates, macros and macro projects in Eplan.

3. Automation of mechanical and electrical design processes based on the configuration in SAP.

For the first time, Eplan demonstrates how the design documents for mechanical and electrical are automatically generated from the configuration in SAP.

4. Automation in mechanical engineering

Automated processing is more relevant than ever for engineering in mechanical engineering. Experts will show the potential scope of engineering.

5. Configuration of circuit diagrams in the cloud

The world of data is moving to the cloud. Eplan eBUILD is a cloud-based methodology that develops engineering sustainably and effectively.

6. Linking an existing configurator to automated engineering

Configurators are increasingly being used in sales and order processing. Users will discover how they can use configuration data for their engineering automatically.

7. Make Eplan data sets available to customers even for highly configurable products

More and more companies are offering their customers access to a wealth of parts data for project planning. Participants will see here how quickly and efficiently data can also be generated for highly configurable products and made available to end customers.

8. Make cabling in complex environments more efficient.

Routing cables is time-consuming and often causes a lot of waste. In this how-to session, participants will learn how to route cables in complex environments more efficiently by using a 3D model and deriving the manufacturing documents for cables and routing from this.

Hands-on sessions: try out the system yourself

The hands-on sessions offer the opportunity to work on the systems themselves. Participants can develop, configure and create a circuit diagram in eBUILD or EEC under guidance. This gives a first impression of what it feels like to work automatically with Eplan. Machine cabling on a 3D model with EPLAN Harness proD can also be conveniently tested here. The cabling can be planned individually, and production documentation can be derived from the planning phase. With the detailed guidance of a moderator, users can achieve their results in a targeted manner. Participation is free of charge. Due to the limited number of places, registration is required in advance.

Time for exchange and networking at the virtual Marketplace

Configuration and automated engineering often go hand in hand. Eplan partners Configit, CONTACT, encoway and SAE will be presenting at the Marketplace. In the periods between the presentations, the opportunity can be taken to talk to speakers, partners and other participants in the networking area. Various stands in the "Marketplace" will provide comprehensive information on the topic of configuration. The spectrum ranges from product configuration and CPQ to methodological topics such as variant management and product structuring. Videos, brochures and short live lectures including a chat option promise exciting insights.

Curious about tips and strategies for the next step on your path to automation in engineering?

Comments