Author

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Electrical Project Documentation: Enabling Precision and Efficiency

Inaccurate documentation is a recipe for disaster, leading to errors in design, delays in production, and costly purchasing errors. An innocent oversight or a minor miscommunication can cause significant setbacks that not only drain resources but also undermine a project's credibility. To avoid these pitfalls, ensuring precise documentation is essential.

In this article, we’ll explain how electrical design software can help to maintain meticulous documentation and increase the likelihood of successful projects.

Why Accurate Documentation Is Critical In Electrical Design

Impeccably maintained and accurate documentation offers many benefits in electrical design and production:

- It acts as an early warning system so that mistakes can be detected before production commences.

- Consistent and precise documentation fosters clear communication between team members, reducing confusion and ensuring everyone is on the same page.

- Accurate documentation helps to ensure that electrical systems are safe, reliable, and efficient.

- It provides a clear and concise record of the design, which can be used for troubleshooting, maintenance, and upgrades.

- Precise documentation can also help to prevent errors and omissions which can lead to costly repairs or even safety hazards.

- Documentation is crucial to prove compliance with regulations and reduce the likelihood of complications post-production.

Improving Efficiency With Electrical Maintenance Software

Maintaining reams of physical paperwork is time-consuming and liable to cause errors, so the problem facing many electrical designers and manufacturers is how to ensure best practice in the most streamlined and efficient way possible.

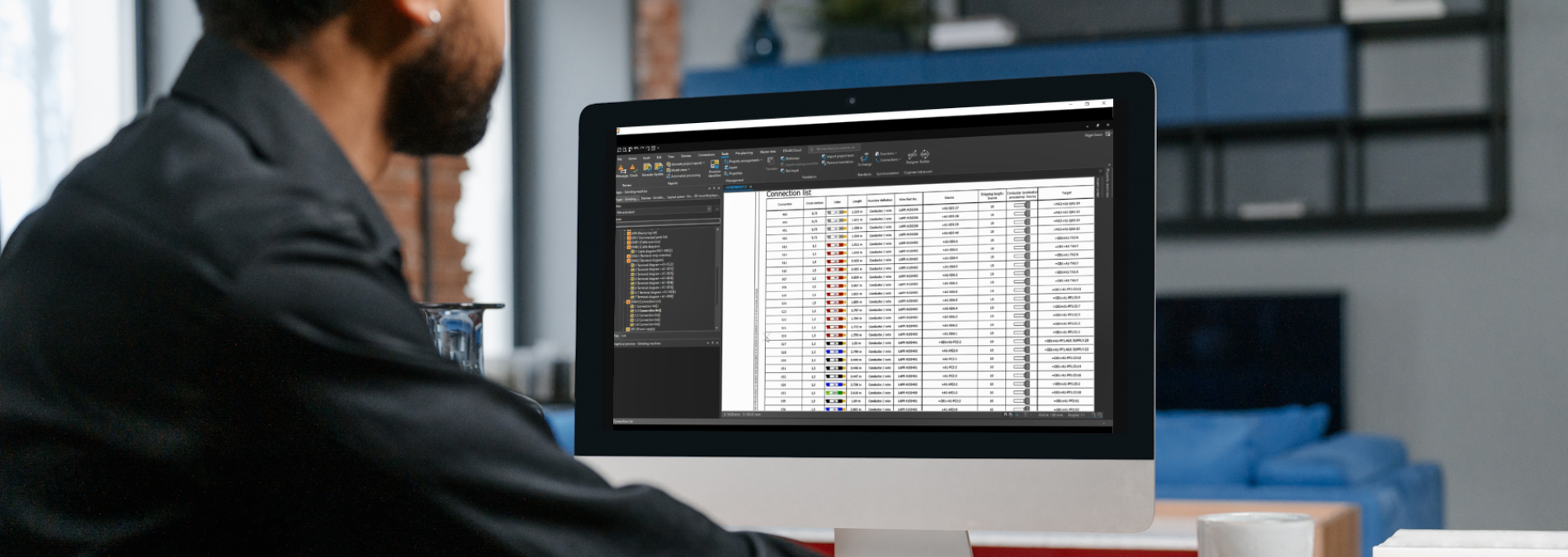

Electrical maintenance software is a powerful tool that not only facilitates best practice but also sheds light on the intricate interactions between different parts. It helps designers and engineers to understand the dependent relationships between each component, paving the way for more informed and trustworthy decision-making.

Thorough record-keeping is vital, too, for efficient knowledge transfer as it avoids the repetition of mistakes, as past problems and their solutions are readily accessible. By minimising reworkings and accelerating the learning curve, electrical maintenance software helps to make every project smoother and more efficient than the last.

Embracing Best Practices

Effective documentation is essential to adhere to best practice. Alignment among team members, clear communication channels, adherence to industry standards, judicious use of automation, regular reviews, and utilising specialist Electronic Computer-Aided Design (ECAD) platforms, such as EPLAN, are vital steps to ensure precise documentation and seamless project execution.

Download Our Free Guide

To find out more about EPLAN and how it can support your record-keeping and documentation, please download our free electrical guide, ‘How to Avoid Electrical Mistakes Getting Through to Production’ or call us on (0)1709 704100.

Comments