Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

Five Reasons for Creating Schematics with Macros

No matter how different schematics may look, there will always be some elements of the project which you have used in the past. Why waste your time starting from scratch? There is so much to be gained from using these read-to-use and already tested schematic parts, macros, in current projects. Here's five good reasons for using macros to create your schematics in EPLAN Electric P8:

1. 50% of Schematics are not Customised

Even if you design the most unique controls or control cabinets, the schematics will always contain fixed or frequently used elements such as motor starters, power lines or circuit breakers. In practice, around half of a schematic can be assembled and copied for unique projects. You simply create the schematic as a macro and store all the possible technical data in its value set. Once this has been saved as a macro project, you no longer have to search through old schematics, thereby saving precious time.

2. Reduced Chance of Costly Errors

At first glance, copying and pasting from earlier projects may seem to be a simple and convenient solution. In practice, however, it often proves to be tricky and time-consuming. In the stress of your everyday work, can you always be certain that you haven’t copied any mistakes into the new schematic? Did you choose the right variant? Are all the necessary components available? If a mistake does slip in and the wrong parts get ordered, that costs both time and money. Using macros helps minimise these sources of error.

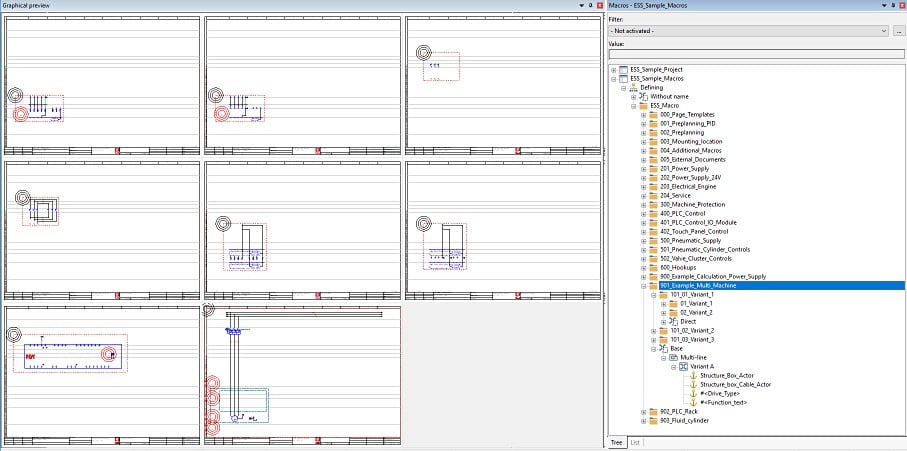

A macro library filled with read-to-use and already tested schematic parts.

3. Simply Select, Drag, and Choose Variant

Using macros means you don’t have to reinvent the wheel for every schematic. You define just once which subcircuits you’d like to reuse and can additionally save different variants of these circuits. For example, you can save a motor control with different power ratings and include the appropriate circuit breaker and fuse for each one. Once set up, all you have to do is add the macro to a project and select the appropriate variant. The corresponding technical values are then displayed and the part numbers stored in EPLAN.

4. Improve Teamwork

Using "copy and paste" for project elements works well when you know exactly what you need and where to find it. However, this method has drawbacks. Your colleagues may struggle to locate specific elements in your absence, especially when team members usually store their own machine-specific device data. This could lead to inconsistencies in schematic representations and lead to temporary downtime.

This is easily preventable by taking advantage of macros. Allowing multiple users to access and use them simultaneously reduces the chance of error or work overlap. The use of macros also ensures uniform device representation across schematics.

By adopting macros, you can enhance teamwork efficiency and maintain consistency throughout your projects.

Is video more your thing? Watch the pre-recorded coffee break session and discover how macros can speed up design, lower costs and allow you to produce higher quality work with fewer errors.

5. Lower Costs and Higher Quality

Time savings aren’t the only advantage macros provide. The standardised way of creating them means your schematics are of even higher quality. All identical devices and components all look the same in all schematics. This also ends up paying off downstream in assembly, procurement and maintenance.

EPLAN's Electrical Schematics Software Solutions

EPLAN Electric P8 has extensive functions and features that make creating macros very easy, allowing you to save any sections or snippets of pages or projects and reuse them in future projects.

New to EPLAN and want to discover the benefits of the solution? Click the link below.

Already got a license for EPLAN Electric P8? Check out the Macro and devices training course to further deepen your knowledge in the field of macro technology and how to apply it efficiently.

Comments