Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Four Good Reasons for Switching to the New Eplan Data Portal

We present you with four good reasons why switching will be worthwhile for you!

1. Take Advantage of the Network Effect

The network effect is a phenomenon that can be seen on social media or community apps (as just two examples): the larger the number of users accessing an offering, the greater the added value for each individual user. Eplan Data Portal is also taking advantage of this effect: manufacturers make their product data available in Data Portal to make Eplan users aware of their offerings. Users, in turn, benefit from a large selection of components from numerous manufacturers brought together in just one application. And companies whose engineering staff consistently work with Data Portal benefit from a solid data basis for the entire value chain.

Right now, around 270,000 users can access up to one million component data that have been provided by more than three hundred manufacturers. The connection to the ePulse cloud environment, which includes even more outstanding engineering applications, creates the best conditions to magnify the network effect to an even greater extent and to increase the added value for users. Free registration is all that is needed to access all ePulse applications.

2. High Data Quality: Standardised Product Data Fit for Everyday Use

Classification standards prevent media disruptions: when the classification standards are used for product descriptions, device data, planning tools and online shops, they support data consistency and data continuity along the entire value chain. This allows everyone to work from the same basis of data, from engineering and production to procurement and even sales. The structural data of eCl@ss Advanced, for instance, makes detailed product description possible. Yet this must be combined with specific practical relevance. This is something that Eplan has worked out in cooperation with both large and small component manufacturers and switchgear system manufacturers. It’s been incorporated into the Eplan Data Standard as a recommendation. Initial results can already be seen in the new Eplan Data Portal.

3. Quickly and Easily Including Data

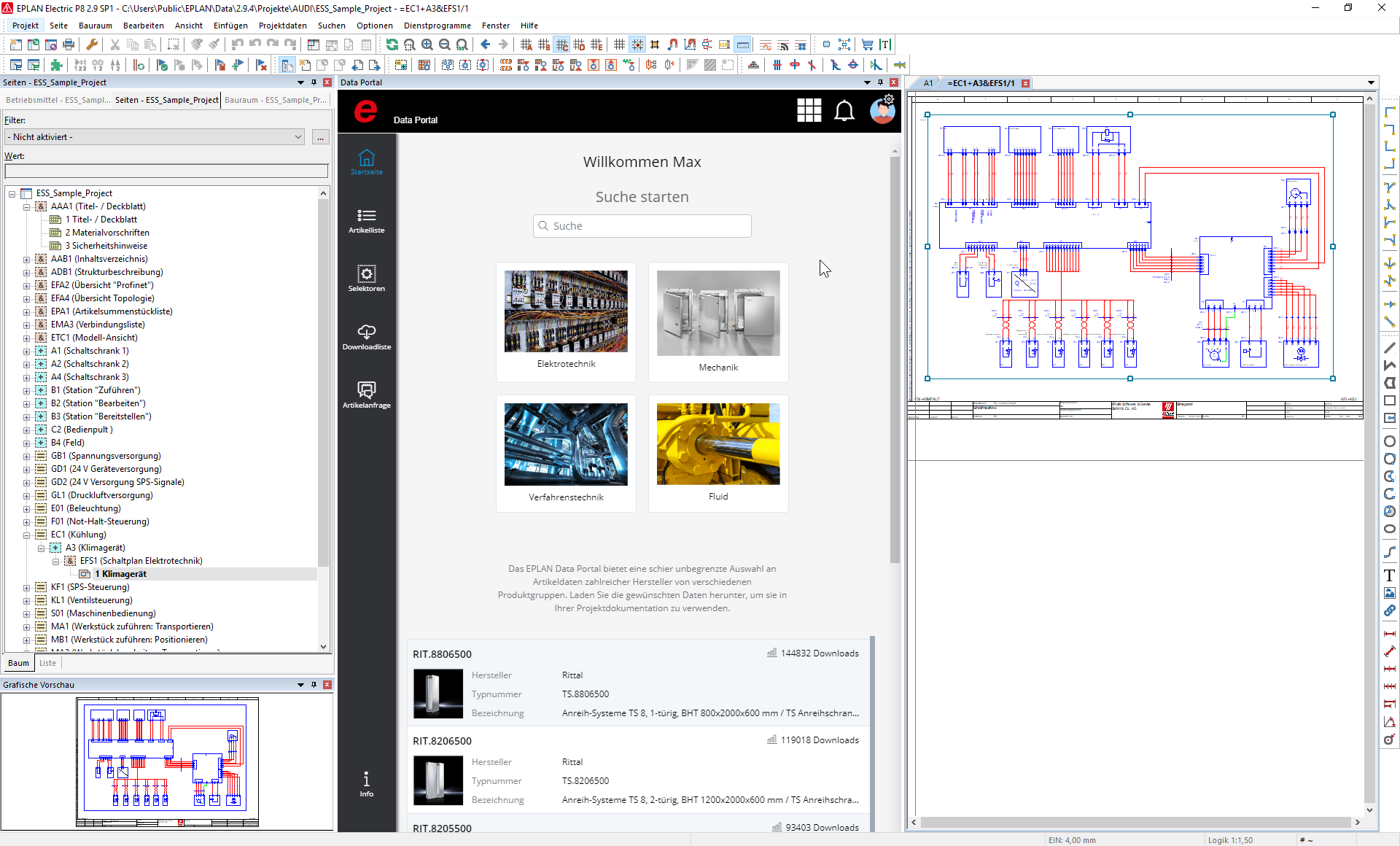

Users can transfer the device and component data in Data Portal directly into their Eplan Projects. Its representation is always based on a uniform source, even in different system plans. This helps make day-to-day work even faster – and it starts from the beginning of project preplanning through to commissioning. The Data Portal’s new user interface is particularly easy to use and, beyond this, the intelligent search function makes suggestions that match previous search behaviour. This way users can find what they are looking for in an even more targeted manner and discover useful additions or alternatives at the same time. Furthermore, several prestigious manufacturers including Rittal, Bosch Rexroth and Schneider Electric offer practical selection aids and product configurators through the “Selectors” function. In the new Data Portal, the Selectors are now placed directly in the main navigator for quick and easy use. For companies, this means more efficiency for their entire engineering process.

Tidy, clear, user-friendly: the new Eplan Data Portal

4. Use This Springboard to the Current Eplan Platform

Admittedly, a new version of Eplan Platform can also mean that users must become familiarised with the new functions during their daily work. But there’s now yet another incentive to do this: with the update to the current Version 2.9, including the “Service Pack 1”, Eplan customers with a Software Service Agreement have access to the new Data Portal in ePulse. And future software updates will be even easier with Eplan Software Service: they are free and included for contract customers. Eplan users additionally receive extensive technical support for questions about the applications, thus making it easier for companies to switch to state-of-the-art technology.

Comments