Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Integrate or Disappear!

It’s a fantastic time for the manufacturing industry. Business is booming but the challenges are increasing. The market demands a shorter time-to-market, lower costs, and better quality. The job market is still tense because the baby-boomers are retiring and there is a stagnated influx of workers with technical training. How can you be successful in the coming year? By integrating!

Every manufacturer can still be successful by having a shorter time-to-market, reducing costs, and improving quality. These objectives can be met with fewer people by using internal resources.

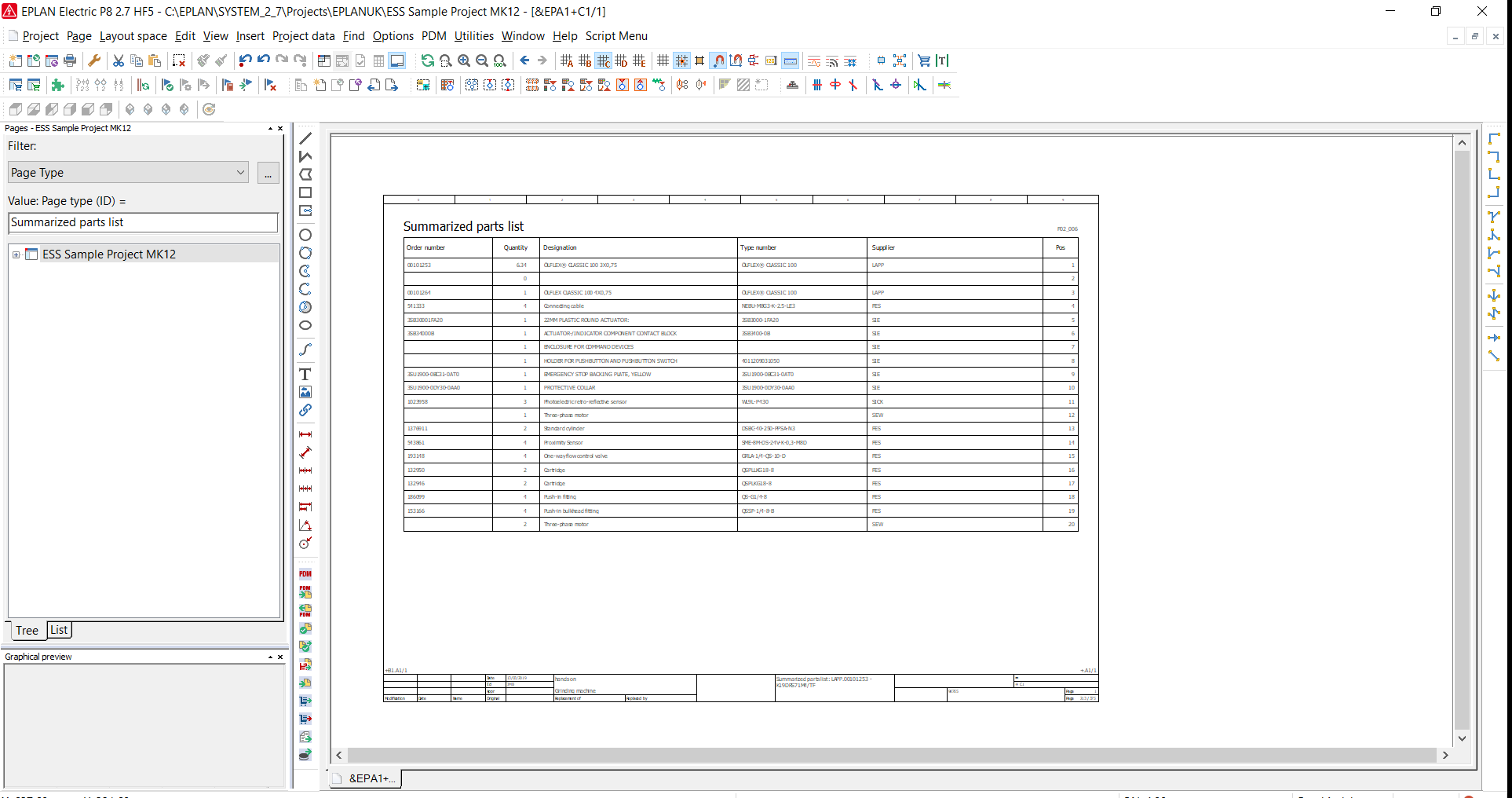

The Bill of Materials (BOM) Explosion

In manufacturing, the different professional disciplines (mechanical, controls and electrical) often work autonomously- everyone has their own system, interpretation, and jargon. Information is exchanged via telephone calls, emails and Excel lists, i.e. by people. Despite their good intentions, the information is often distorted or incomplete. This means that you can't control the different bill of materials (BOMs) from MCAD (mechanical) and ECAD (controls). Miscommunication usually leads to mistakes like double the amount of parts or not enough parts being placed on the BOM, which then results in delays and high costs.

Automatically generated BOMs avoid errors like double or not enough parts being ordered.

3D-EIntegration is Key

Luckily, it doesn’t have to be like this. An extensive information integration is crucial to confront the challenges of tomorrow. That’s why large companies supplement their Enterprise Resource Planning (ERP) system with a Product Data Management (PDM) system or Product Lifecycle Management (PLM) system. More and more small and medium companies recognise the need to have a system like this. Why?

MCAD and ECAD

Thanks to the PDM/PLM system, all of the affected disciplines (electrical, mechanical and software, purchasing and sales) work with the same, standardised product database. Communication is now automatic rather than via email or Excel lists because all of the underlying systems are joined to each other. Unfortunately, we often only see that the mechanical information (MCAD) is included. In the meantime, control systems demand a greater role in manufacturing. To integrate your work processes, the ECAD systems must integrate so that departments can share information transparently.

This results in a unified integration. The right part numbers on the right BOM- without doubling the amount and nothing has been forgotten. Changes during the project are detected and dealt with automatically meaning that success doesn’t depend on accidental human communication.

Optimise Engineering

Information integration is the key to success in the current market. But it can only succeed when all disciplines are connected to one another, including your ECAD system. Only then can you completely improve and optimise the engineering process, which leads to a reduced chance of mistakes, the prevention of additional costs, and a shorter the throughput-time.

Comments