Author

Tony Ward

Tony has been working successfully as a Regional Sales Manager in the UK for the past 16 years. This has involved dealing with companies of all sizes, understanding their situation and business issues in order to offer the right solution to them. Successes of note have been Nissan in the UK and James Fisher Nuclear. Tony has also worked on international accounts such as Coca Cola, being responsible for the sale and roll out of EPLAN across the UK.

ward.t@eplan.co.uk

Tony Ward auf LinkedIn

Tony Ward

Tony has been working successfully as a Regional Sales Manager in the UK for the past 16 years. This has involved dealing with companies of all sizes, understanding their situation and business issues in order to offer the right solution to them. Successes of note have been Nissan in the UK and James Fisher Nuclear. Tony has also worked on international accounts such as Coca Cola, being responsible for the sale and roll out of EPLAN across the UK.

ward.t@eplan.co.uk

Tony Ward auf LinkedIn

Is EPLAN worth the investment?

EPLAN is suitable for large and small organisations alike, as it‘s a cost-effective option for many reasons. EPLAN‘s basic features provide a large amount of advanced options, making it more affordable than other software packages which often require additional modules to achieve similar functionality.

As of August 2021, EPLAN exclusively offers licenses on subscription, and as a result, the entry price for switching to EPLAN has dropped significantly. By investing in subscription rather than perpetual licenses, you’ll benefit from the subscription fee being inclusive of everything you need to run the software, as well as technical support. Ultimately, it’s much cheaper to invest in subscription software.

While the lower upfront investment of EPLAN ensures that the software package is more accessible than ever, that’s not the end of the financial savings. Using dedicated ECAD software can mean significant time savings; from planning and designing, through to documentation, edits or changes in production, and future adjustments down the line.

Automating your design is not, nor should it be, a trivial investment. But think about this: if your investment reduced your design times by up to 80%, what would that mean for your company? What about if that initial investment also means you deliver better products with fewer mistakes, minimising the need for modifications or changes? Wouldn’t the cost be recovered quickly because of the time savings and extra profit you’ll be making?

Let’s look at a real-life example. A business we spoke to recently told us:

“2 days per project is spent updating the schematics because of missing data. I manage 36 projects per year and there are 4 engineers in the team responsible for updating the project.”

Engineers day rate = £200

x2 days

x36 projects

£14,400

£14,400 x 4 engineers = £57,600

They also told us that they “can easily spend 2-3 days at the end of every project making changes” due to errors.

Manual workflows introduce mistakes that are often found in production. With EPLAN’s automated processes these mistakes can be minimised. The use of macros and the ability to reuse circuits that have already been checked and approved speeds up the design process and eliminates design errors.

Automated features such as device and wire numbering remove mistakes caused during manual workflows. Not forgetting the auto-generation of reports such as BOMs, connection lists and wire markers ensuring that the data passed to production is accurate and reliable. These automated workflows promote faster engineering processes with data you can trust.

Considering the above example has saved £57,600, it’s easy to see that when you compare the cost of purchasing EPLAN to this saving alone, the benefits gained using EPLAN far outweigh the investment made.

It’s worth noting that there are many other areas in which time savings (and ultimately, money) can be made. Here are just two examples:

Wire Numbering

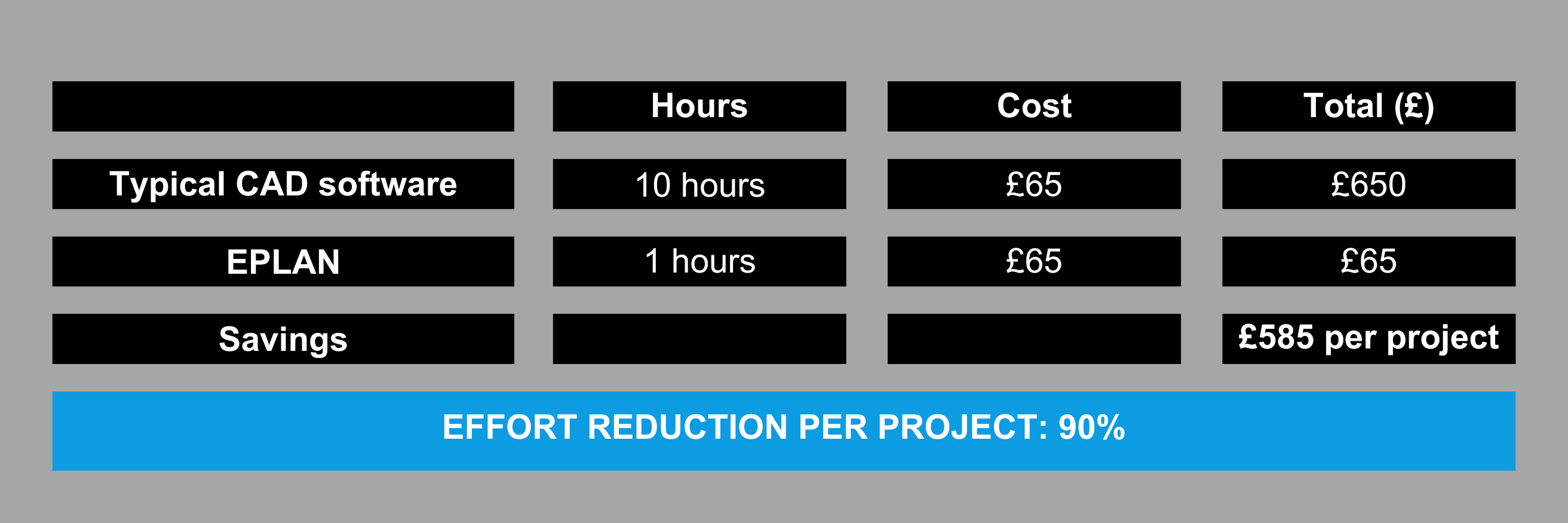

To renumber a 100-page project, let’s compare the time and cost taken using traditional CAD packages to EPLAN:

Estimated cost of £65/hr for numbering wires

In a traditional CAD system, wire numbers are entered manually, and in some cases often in a separate document (in Excel© for example) where they’re not linked to the original drawing. This process is time-consuming and prone to errors. With EPLAN, pages, devices, cables and wires are automatically numbered and can be achieved with just a few mouse clicks. The export of wire/cable and device markers are also generated automatically.

See how easy wire numbering is to do within EPLAN!

Manufacturing Reports & Drawing packs

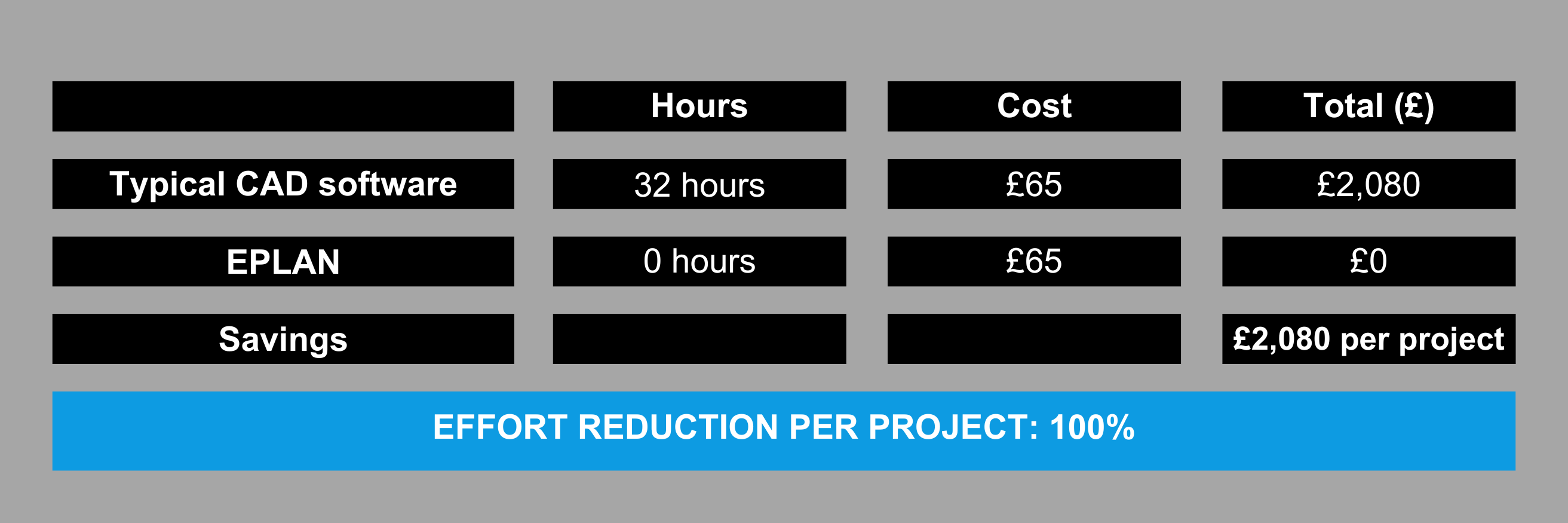

To produce and extract all relevant reports and documentation for a typical project, let’s compare the time and cost taken using traditional CAD packages to EPLAN:

Estimated cost of £65/hr for generating reports & documentation

Cable schedules and BOMs are completed manually in traditional CAD software packages and can take days to generate. This process is time consuming which often results in errors, and usually consists of a combination of DWGs and other file formats.

With EPLAN, 35 different reports can be automatically generated simultaneously, including BOMs, wire lists; cable diagrams; cable termination sheets; terminal diagrams; parts lists; device connection diagrams etc. These reports can be generated within the project or to an external file format such as Excel. This eliminates errors creeping in, and substantially reduces the amount of time required to produce all required documentation. With EPLAN, you’ll have a complete project ready to send to customer and/or third party where all information is stored in one file/project.

Watch video tutorial: EPLAN ELECTRIC P8 Tutorial to Generate Reports

In addition to substantial time savings for the engineering department, EPLAN also improves the entire engineering process upstream and downstream:

- Sales / Quotations: typically, a concept is drawn on paper and then passed to the engineering department, but many problems can arise during the design phase. This can delay delivery times and run the risk of unhappy customers. With EPLAN, engineering concepts can be drawn up as part of the sales process, ensuring that the concept is feasible. That initial design concept can also be used in the engineering phase to speed up the design process!

- Manufacturing & shop floor: EPLAN automatically provides a myriad of data and information for the manufacturing process, including labelling, enclosure cut-outs and drilling, panel layouts, wiring and more. By doing so, all data sent from the design office to the shop floor is reliable and trustworthy, therefore eliminating the need for rework due to menial mistakes. The benefits of EPLAN are also found in production; while finding skilled shop floor personnel is becoming increasingly difficult, EPLAN offers a variety of virtual assistant tools, including solutions which make panel wiring easier!

Find out more about Smart Wiring with EPLAN

By embracing EPLAN, you‘re embarking on a path towards streamlined efficiency, precision, and innovation. Our comprehensive suite of tools is designed to empower you, providing intuitive solutions to your most intricate design challenges. Your journey to intelligent, smart designs begins here with EPLAN.

Comments