Author

Tony Ward

Tony has been working successfully as a Regional Sales Manager in the UK for the past 16 years. This has involved dealing with companies of all sizes, understanding their situation and business issues in order to offer the right solution to them. Successes of note have been Nissan in the UK and James Fisher Nuclear. Tony has also worked on international accounts such as Coca Cola, being responsible for the sale and roll out of EPLAN across the UK.

ward.t@eplan.co.uk

Tony Ward auf LinkedIn

Tony Ward

Tony has been working successfully as a Regional Sales Manager in the UK for the past 16 years. This has involved dealing with companies of all sizes, understanding their situation and business issues in order to offer the right solution to them. Successes of note have been Nissan in the UK and James Fisher Nuclear. Tony has also worked on international accounts such as Coca Cola, being responsible for the sale and roll out of EPLAN across the UK.

ward.t@eplan.co.uk

Tony Ward auf LinkedIn

Legacy CAD Data: ECAD Migration Challenges Debunked

Many traditional CAD packages are very good if you need to produce 2D drawings or 3D models of mechanical components, and they will save you a lot of time compared with producing similar drawings by traditional manual methods. You can draw almost anything with a good CAD system, including basic electrical schematics. So, if you’ve never used a dedicated ECAD system, you may well be convinced that your current CAD software is all that you need. And that’s true if you don’t mind missing out on a whole range of benefits that can hugely improve productivity and profitability.

Switching out your existing CAD software to another can feel like a daunting task, especially when it comes to preserving historical data and transferring said data into a new system.

Issues with Legacy CAD Data

Electrical design data is an asset which requires constant access in order to ensure that the current product lifecycle is supported. However, in reality legacy data in most companies is often problematic for various reasons:

- Legacy drawings may well have become unusable due to obsolescence in hardware, CAD systems, operating systems, and expertise

- Quality issues or inconsistencies due to multiple revisions, and changes not being communicated

- Engineers not working to the same standards, and possibly implementing their own workarounds

- Legacy data doesn’t necessarily provide the full range of required information as it doesn’t take into account any new engineering requirements

- The possibility that legacy data may not have followed data governance and/or codes & standards at the time of creation

- Customers often request a copy of the project in the latest ECAD format

- Legacy data may contain errors which have not been previously identified

Studies show that there is only a small amount of useful CAD data that engineers actually utilise. There may be a slightly larger amount of data that is sometimes used, and the rest never referred to. The solution is then to first filter out the critical data and then work on its conversion following a standard design process rather than converting each and every legacy file.

Preserving Legacy CAD Data

For some who make the switch, a major obstacle to successful implementation is getting legacy CAD data (including database information, files, revision histories, custom properties, file relationships, etc.) into the new system quickly, in an organised manner, and most importantly, with no loss of information.

There is a perception that it’s not easy to migrate data into a new system, however, moving your design data can be made easier provided proper planning, a good strategy, strong methodology, testing and that the right people are included as part of the process.

Although you may be aware that the future benefits are huge for your team, the transition phase may feel lengthy and confusing. Afterall, how are you to find the time to get it up and running? At EPLAN, we aim to make your journey from CAD data to intelligent, smart designs as simple and quick as possible through various expert services and resources.

EPLAN CAD Migration Solutions

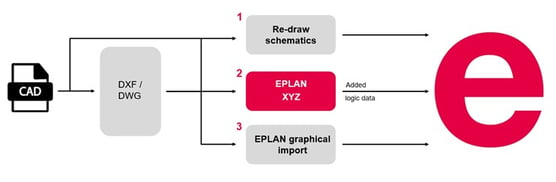

More often than not, design data generated in traditional CAD tools has little data attached to the drawing, so when it is imported into a dedicated ECAD solution, there is no intelligence there to transfer. However, if you are looking to switch to EPLAN and would like to migrate your existing project data, there are three options available in order to make the transition less painful:

Option 1 – EPLAN Re-Draw Service. EPLAN have a local team of experienced engineers available to redraw existing projects into an EPLAN project. All you need to do is provide us with the original project in DXF or DWG format and any additional information such as part and connection data.

Option 2 – EPLAN Import Service. EPLAN can provide a service whereby not only can DXFs or DWGs be imported into an EPLAN Project, but also additional data can be imported into the project such as Page Structure, Devices, Terminals, Connections, Reports and Standard Symbols.

Option 3 – Graphical Import. This simply allows projects to be imported from DXF or DWG into EPLAN. The imported pages are graphical drawings only but can be modified with various editing tools. The drawing remains graphical and there is no intelligence attached, but this gives the ability to store the pages as an EPLAN project.

Customer’s Transition to EPLAN

A Yorkshire based company Magma Group eased their transition to EPLAN by contracting EPLAN’s engineers to set up their working standards within their system and transfer vast amounts of data from legacy projects. In total, EPLAN’s engineers transferred data for 4,500 parts - which had been used to create legacy projects - and turned it into EPLAN data. This saved the Magma team 450 hours! In addition, the working standards provided them with guidelines that both their engineers and sub-contractors could work with to ensure consistent, high-quality service at every stage of the process.

The data migration has never been this easy to solve, helping to make the switch to EPLAN a stress-free process.

Comments