Author

Simon Jackson

Simon joined EPLAN in the summer of 2016 as the Area Sales Manager for the North West region and hasn’t looked back. Originally a Production Engineer, Simon moved into sales in order to make a difference and become closer to the manufacturing industry in the UK. Previously responsible for selling PCB CAD software in both the UK and northern Europe, he now gets a real buzz from the reaction he gets when talking to prospects and customers about the efficiencies and improvements that EPLAN software and services can bring to such a wide variety of businesses. He believes the whole philosophy of “efficient engineering” and the EPLAN Experience is a message that so many should hear.

Jackson.S@eplan.co.uk

Simon Jackson auf LinkedIn

Simon Jackson

Simon joined EPLAN in the summer of 2016 as the Area Sales Manager for the North West region and hasn’t looked back. Originally a Production Engineer, Simon moved into sales in order to make a difference and become closer to the manufacturing industry in the UK. Previously responsible for selling PCB CAD software in both the UK and northern Europe, he now gets a real buzz from the reaction he gets when talking to prospects and customers about the efficiencies and improvements that EPLAN software and services can bring to such a wide variety of businesses. He believes the whole philosophy of “efficient engineering” and the EPLAN Experience is a message that so many should hear.

Jackson.S@eplan.co.uk

Simon Jackson auf LinkedIn

Machine Cabling Made Easy

Still Guessing Cable Lengths?

Planning the cables between machines and control cabinets can be a daunting task. Questions such as what cables to use, how to plan them, and how long they should be can make the process tedious. Unfortunately, it is not uncommon for the planning to be carried out without precise specifications, leading to varying results and material waste.

Additionally, surprises such as cut outs or drilled holes that are too small can slow down the assembly process if they were not considered during the planning phase. Without accurate 3D prototypes, achieving a uniform appearance for the cabling is nearly impossible.

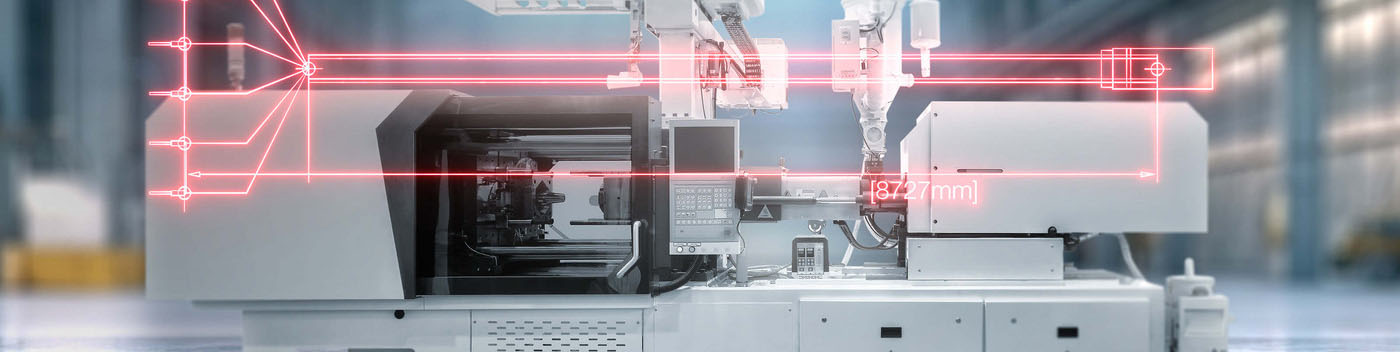

3D Model of the Machine, Control Cabinet and Complete Cabling

All this is much easier with the right software! Electrotechnical 3D CAD systems such as Eplan Cable proD make it possible to depict 3D components of machines, the cabling and the associated control cabinets. And it can be accomplished without any training on complex MCAD software. Once the electrical designs are complete, the 3D representation of the cabling can be transferred to a 3D MCAD system.

This allows, for instance, collision checks to be run and the electrical design team can quickly clear up any issues as needed. The 3D model can also be used as a virtual prototype during ongoing assembly processes.

Digital Twin of the Machine Cabling: Advantages for Planning

- Plan and visualise cable routing, drill holes and cut outs

- Determine cable lengths during the planning process

- Order prefabricated cables from the manufacturer long before they will be installed

- Define clear specifications for assembly and clearly depict them

Digital Twin of the Machine Cabling: Advantages for Assembly

- 3D model available as a digital prototype for standardised cabling

- Prefabricated cables can easily be connected

- Trouble-free assembly and customer approval

- Reduced material consumption reduces production costs

Increased Productivity Via Prefabricated Cables

Designing components and cabling on a 3D model with clear specifications and preassembled cables makes installation simple, even for those with less experience. The digital depiction of your cabling allows for precise material requirements to be determined early on, making it easy to place orders for everything you need.

Additionally, Eplan offers an HTML export feature that allows assembly technicians to see exactly how engineers planned for the cables to be installed, ensuring a trouble-free installation process with early problem recognition and avoidance. This results in increased efficiency and higher quality throughout the entire process. According to Eplan Product Manager Germany Lukas Menzel, "Eplan Cable proD fundamentally changes the process of machine cabling and enables the efficient use and installation of prefabricated cables."

End The Guesswork

One cost driver in machine engineering is field cabling, where cabling often ends up being either too short or too long. Why is that? Because working by trial and error is still too often used these days. Eplan Harness proD software, which was previously used for designing wire harnesses, has now been expanded to also include machine field cabling. The digital twin can be used as a 3D module in the mechanical construction or be transferred into the electrotechnical project with the added cabling information.

Finding the right cables, planning, designing and plotting their routing for assembly? Until now, this has been a very laborious process for electrical design engineers in machine building. Solutions provider EPLAN has now expanded its 3D software Eplan Harness proD to cover the practical requirements for machine field cabling. What’s long been standard in the mechanical environment is now moving into electrical engineering – the digital twin of the cabling. Depicted in EPLAN Harness proD, this unique product data source is usable in manufacturing, assembly and even service and maintenance – by combining electrical and mechanical engineering. The common device database for the EPLAN systems ensures an unambiguous source for all the data. One clear advantage in practice is that every designer can work in their own way, each with their own view of the machine in question: mechanical engineering continues working with assemblies and electrical engineering with functions.

Final Thoughts

Machine cabling no longer needs to rely on trial and error. With Eplan Harness proD, manufacturers and design engineers gain an intuitive tool that bridges the gap between mechanical and electrical engineering.

By integrating digital twin technology early in the planning process, teams can reduce material waste, avoid costly errors, and significantly accelerate installation and commissioning. From precise cable length calculations to prefabricated assemblies and seamless communication between departments, our software transforms cabling from a bottleneck into a streamlined, strategic advantage. It’s time to move away from guesswork and towards a smarter, more efficient future.

Comments