Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Find the right component faster | The new Eplan Data Portal

Data is the new "oil in engineering". It is used around the clock in electrical engineering and is crucial when it comes to component data. Just imagine if this data is consistently available digitally and if users can find it quickly. The Eplan Data Portal provides the central database to make this a reality.

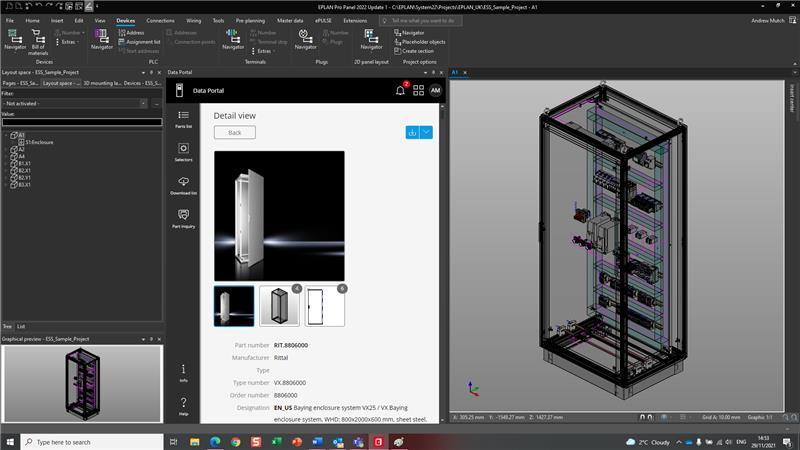

In the database there are around one million components from 344 manufacturers currently available. With the release of Eplan Platform 2022, the portal has also received an update in terms of usability. The new user interface is more fun to use, while at the same time, making searching for and finding device data easier and faster thanks to the increased performance of the system.

Over a third of all data in the Eplan Data Portal - for example from Rittal - already represent the new, high-quality data standard.

Over a third of all data in the Eplan Data Portal - for example from Rittal - already represent the new, high-quality data standard.

Easier to select products using the configurator

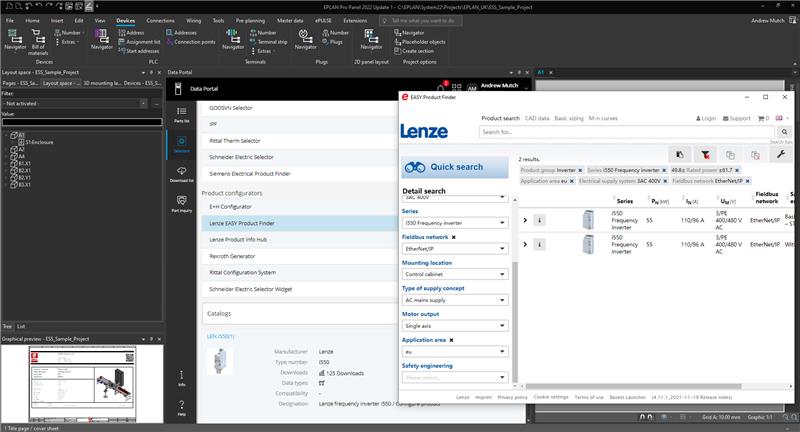

Individual solutions based on configurators can also be generated intuitively - as the Lenze product configurator shows. Bernd Spiegel, Head of Team Processes and Data at Lenze, explains: “The direct connection of our product configurator to the new Eplan platform allows the customer to find the product they want very quickly. There is no need to search for items in extensive lists and the customer receives an item that meets his requirements."

Using configurators such as the Lenze Easy Product Finder, portal users can find a suitable device from the i550 series in just a few steps.

Using configurators such as the Lenze Easy Product Finder, portal users can find a suitable device from the i550 series in just a few steps.

The solutions from manufacturers such as Bosch Rexroth, Endress + Hauser and Rittal also work in this way. This makes the portfolio of these manufacturers intuitively accessible. As with the configuration of a new car, users are guided through various product families of the manufacturer quickly and easily. In addition, there are selectors from Aventics, IPF and Schneider Electric, which, with a targeted filter using search parameters, ensure fast, reliably correct product selection. This portfolio will soon be expanded to include two more well-known global players - users can already be excited.

Ambitious: Driving the Data Standard further

Over a third of all data in the portal already reflects the new, high-quality data standard, and the goal is ambitious: by the end of 2022, half of all article data should meet the data standard. This calls for further commitment on the part of the component manufacturers, who are increasingly recognising the advantages of 100% digital data. The pioneers on the international stage were big players such as Chint (China), IFM, SMC and Pilz (Europe), Numatics (USA) and Omron (Japan).

From practice: Macros standardised by Pilz

Arndt Christ, Pilz Vice President Customer Support International, says: “We are delighted that we can offer our customers high-quality engineering data today. In 2020 we decided to create our Pilz product macros in accordance with the Eplan Data Standard. Our customers around the world benefit from the standardisation of the data that is now possible, which makes handling the macros easier. In the past, macros had to be inserted into the plan using sets of values, however, today this can done simply using the function template. The advantages: better networking of the data - for example between 2D and 3D -, fewer errors, since the connections for the wiring are precisely defined, and, above all, time savings because the macros are standardised."

The digital twin | For 100% digital data

“These high quality standards of the manufacturers correspond to the demands of our users. After all, only comprehensive, consistent data is the basis for a digital twin that supplies the processes and machines with information in all stations from engineering to production. It is our goal that component data are 100% digitally available and thus offer an ideal basis for highly efficient engineering."

Timm Hauschke, Director Cloud Business Master Data at Eplan.

More information about the Eplan Data Portal can be found here.

Comments