Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

No time for automated engineering? No more excuses!

The digital transformation, automation, standardisation – these are topics that have been on the agenda for established industrial companies for years but haven’t yet made it into the everyday working world. The cloud-based solution Eplan eBuild is now offering a new methodology that makes it easier to get started with automated engineering. The concept is to automatically generate schematics, to easily re-use templates, and to take advantage of cloud-based libraries to standardise engineering processes.

> Find out more about EPLAN eBUILD

So there’s nothing more standing in the way of automated engineering, right? Below you'll find the five excuses for not taking on the topic of automation – and deliver good arguments about why you should do it anyway!

1. "I'm in the middle of a crisis! Now isn't the time to be investing in digitalisation"

Yes, it is. Particularly in times of crisis, it’s important to keep an eye on the future. This is how a majority of company decision-makers see it, as a recent survey by Pegasystems shows. Viewed globally, 62 per cent of those surveyed said that they want to give higher priority to the digital transformation moving forward, while another 56 per cent intend to specifically increase their investments in this area.

Even disregarding the crisis for a moment, it is and remains crucial for companies to continuously be open to further development so as not to be left behind by the competition. As the DACH Director of Professional Services Uwe Harder explains: “Many companies are faced with the problem of national and international competitive pressure and have the task of somehow becoming more efficient in their processes. We’re all talking about digitalisation, about the ‘digital twin’, about paperless manufacturing. The root of all these undertakings is, of course, to increase the quality of engineering.”

Even disregarding the crisis for a moment, it is and remains crucial for companies to continuously be open to further development so as not to be left behind by the competition. As the DACH Director of Professional Services Uwe Harder explains: “Many companies are faced with the problem of national and international competitive pressure and have the task of somehow becoming more efficient in their processes. We’re all talking about digitalisation, about the ‘digital twin’, about paperless manufacturing. The root of all these undertakings is, of course, to increase the quality of engineering.”

2. "We don't have enough personnel for it. We can barely keep up with our current daily business."

Whether you’re in an upswing or a crisis: the shortage of skilled workers is an ongoing issue in machine building and control cabinet engineering. Companies often have just enough employees to handle their daily tasks. So why tie up capacities for realising automation projects? Quite simply because it’s almost always worth the effort! One of the things automating engineering processes can do for companies is to ensure that copy-and-paste errors no longer happen when creating schematics and furthermore enormously reduces the amount of time spent designing engineering projects by hand.

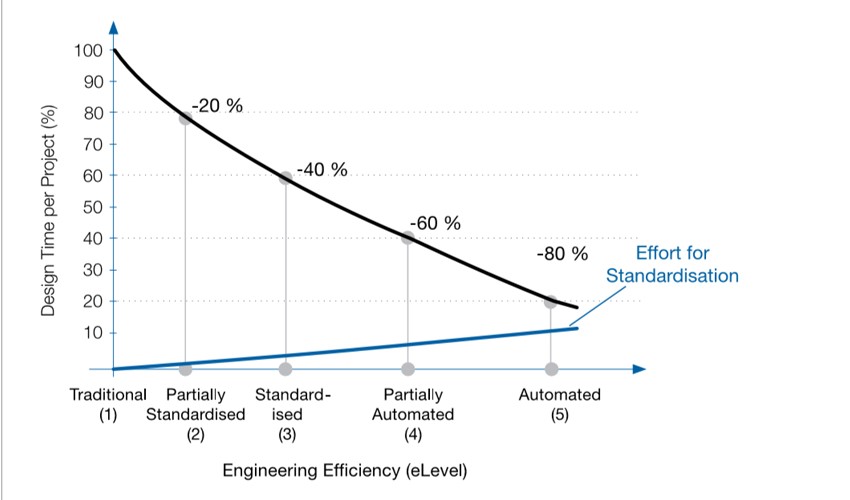

The Engineering 4.0 study by Eplan and the European 4.0 Transformation Center at RWTH Aachen University divides the path from manual to fully automated engineering into five steps, what they call eLevels. It makes recognisable the enormous potential each increase in eLevel can unleash for companies. Compared to more conventional schematic creation, using a circuit library for product functions (eLevel 3) can save up to 40 per cent of the time needed, while partial automation (eLevel 4) can even save up to 60 per cent of the necessary time. Of course, “levelling up” also means firstly having to invest in the standardisation process. But, as the study shows, this ends up being worthwhile for most companies – even up to the highest levels of efficiency (see the graph).

The higher the targeted eLevel, the greater the efforts for standardisation will be. In relation to this, the design time for engineering projects also decreases considerably up in the higher eLevels. (Source: Engineering 4.0 study)

3. "Standardisation, automation... it all sounds good in theory, but we're on our own for implementation!"

Every company has a type of individual “sweet spot” that represents the perfect balance between manual efforts and standardisation efforts. But how do you specifically find out where you and your company stand and what optimisation potential lies dormant in your process and IT infrastructures?

EPLAN's services can support you in determining your company’s current eLevel and effectively increasing it. “We offer companies comprehensive workshops, certification opportunities and consulting services with knowledgeable experts using proven methodologies,” says EPLAN Senior Vice President for Global Professional Services Bernd Schewior. “We use these to then derive specific recommendations customers can use to get started with their projects. By the way, all of our consulting services can also be taken advantage of online using remote access.”

EPLAN's services can support you in determining your company’s current eLevel and effectively increasing it. “We offer companies comprehensive workshops, certification opportunities and consulting services with knowledgeable experts using proven methodologies,” says EPLAN Senior Vice President for Global Professional Services Bernd Schewior. “We use these to then derive specific recommendations customers can use to get started with their projects. By the way, all of our consulting services can also be taken advantage of online using remote access.”

4. "We're just a small company. The efforts required for introducing automation aren't worth it for the one or two employees in engineering."

The Engineering 4.0 study also shows that automated work methods can be worthwhile irrespective of a company’s size. The positive effects of the time savings are all the more evident when there are only a few employees. Every minute a user of engineering software doesn’t have to spend manually creating schematics or correcting correct copy-and-paste errors is time that person can use for more complex tasks. In short: standardisation and automation create time for new ideas and innovations – and also the time to make smaller companies grow.

5. "It will take far too much time to clean up our EPLAN database."

Admittedly, as soon as it comes to bringing engineering processes to a new eLevel across an entire company, you need experienced users. They must be familiar with the associated software and ready to create standards instead of falling into old work habits and eyeballing it. The only way the entry into automated engineering can succeed is with a “clean” foundation.

That’s the principle the full version of EPLAN eBUILD is based on – users who have in-depth knowledge of the EPLAN macro technology set up standardised template libraries with frequently used sub-circuits. These can then be made available for use within the entire company in the cloud. This foundation makes it possible for employees with very little knowledge of EPLAN to create schematics automatically with just a few clicks. Not to mention, companies and users aren’t left to their own devices when it comes to creating the foundations for this engineering: “One of the things EPLAN offers is substantial support for systematically setting up macro libraries in EPLAN Electric P8, as well as individual consulting and product training for users,” Schewior says. “Even if we need to get a particular employee up to speed, we can help by providing him or her with an EPLAN Personal Coach.”

Still not convinced that the path to automated engineering is worth it? Then simply try it out for yourself with EPLAN eBUILD Free!

Automatically generate schematics using tested templates provided by EPLAN experts and prestigious manufacturers. This is made possible, free of charge, by the EPLAN eBUILD Free version of the software which is available at www.eplan.com.

Comments