Author

.png?length=68&upsize=true&upscale=true&name=Untitled%20design%20(16).png) Kelly Moore

Kelly Moore is a Marketing Executive for Rittal and Eplan UK. She has worked for both companies for a year and loves the 'people' side of the business.

kmoore@rittal.co.uk

Kelly Moore auf LinkedIn

Kelly Moore

Kelly Moore is a Marketing Executive for Rittal and Eplan UK. She has worked for both companies for a year and loves the 'people' side of the business.

kmoore@rittal.co.uk

Kelly Moore auf LinkedIn

Production Up to 30% Faster with Eplan: A Q+A with SPIE BTAT

Q: What does digitalisation mean for SPIE BTAT, and what made you address the issue?

A: For us, digitalisation primarily means increasing the efficiency of our processes while at the same time addressing the skilled workers shortage in the field of switchgear construction. In digitalising our processes, we are creating uniform and simplified workflows. It was an important goal to ensure consistent data integration by means of digitalisation. This is helping us minimise errors and save time as well as effort. Particularly in the area of switchgear design, we were aiming for using modern digital tools in order to achieve greater flexibility and speed but without affecting the quality.

Marcel Luttmann, Electrical Engineer and Project Planner at SPIE BTAT (photo: SPIE BTAT)

Q: So, you use Eplan software in combination with the Weidmüller Configurator. How has this changed your way of operating?

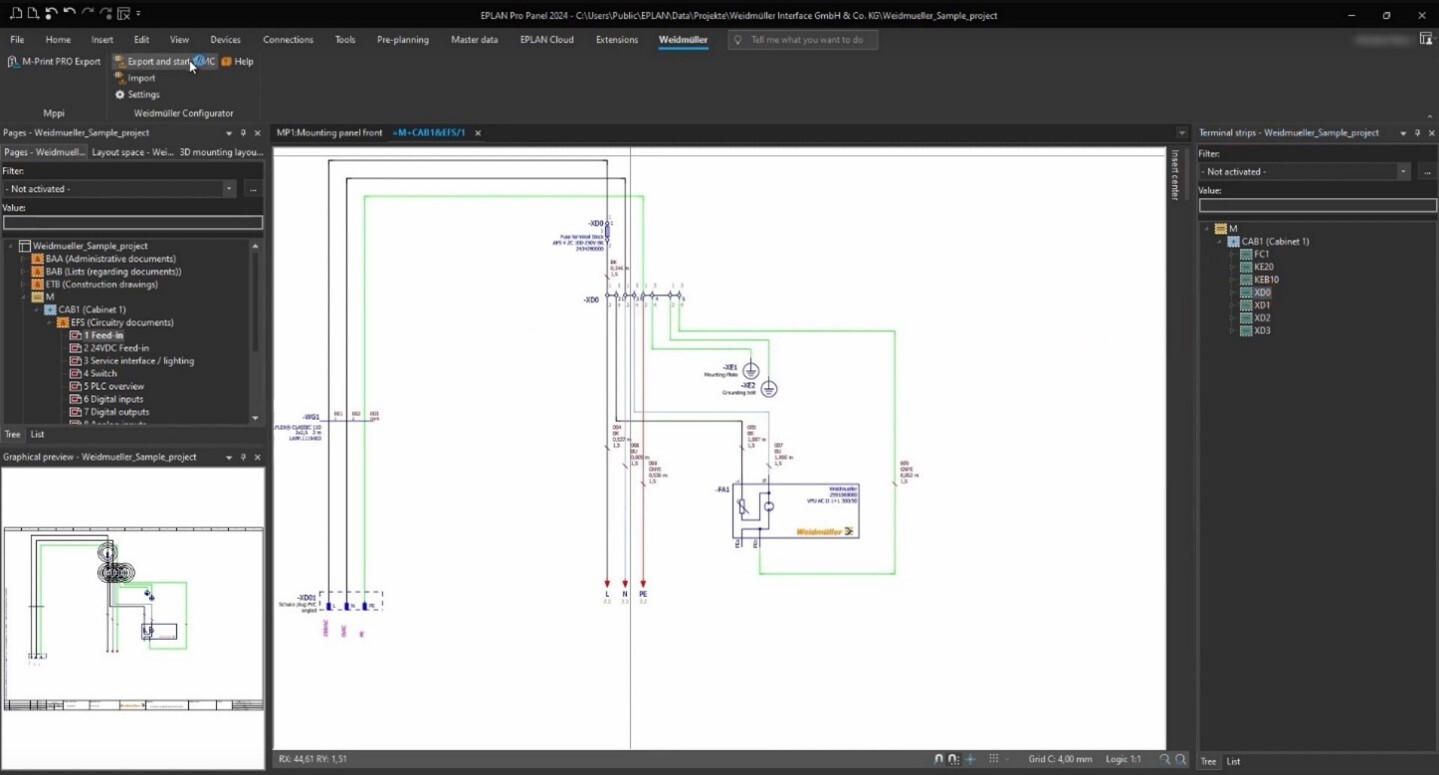

A: The implementation of 3D design with Eplan Pro Panel has been in place for more than two years now and we have been using the Weidmüller Configurator even longer. Having the Eplan Electric P8 as the basis in addition to the 3D component through Pro Panel, we profit from extensive digital manufacturer data, which allows us to model the switchgear constructions in a much more detailed and precise way already during the design phase. The switch to Eplan Pro Panel needed some time, but the long-term gains as far as efficiency is concerned are unmistakable.

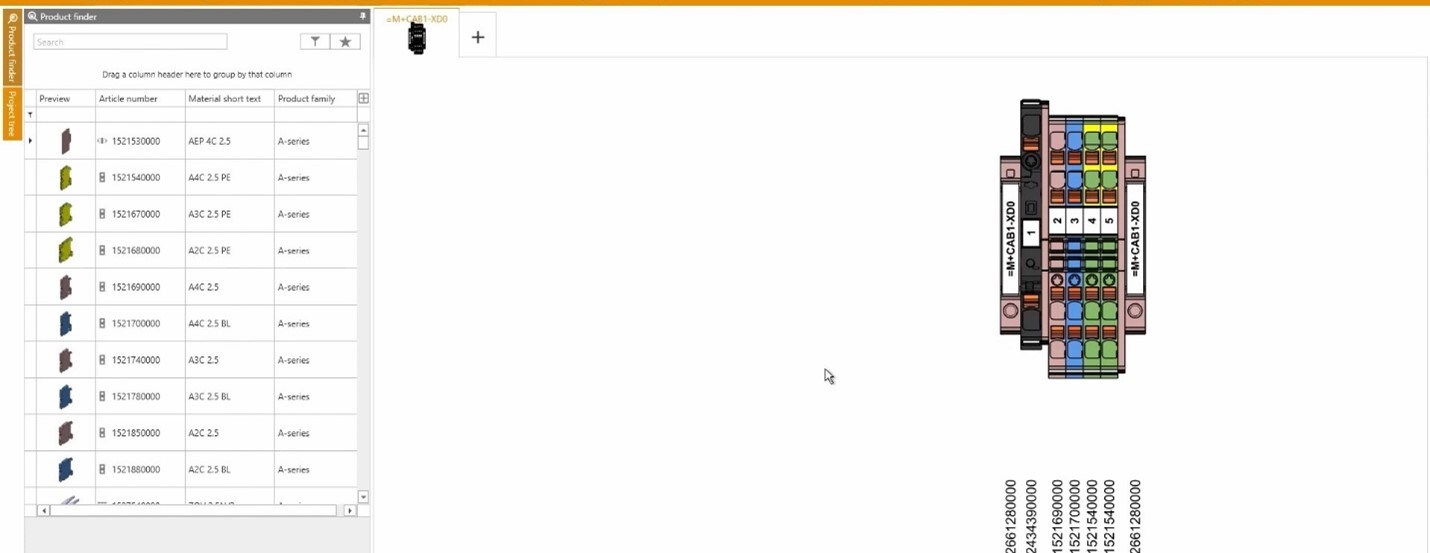

The existing integration of the WMC – i.e. the Weidmüller Configurator – enables us hereby, for example, to create terminal strips directly based on the design data from Eplan and transfer them to the production with all the necessary accessories. We assemble the terminal strips ourselves in our production facility, and thanks to the precise data from the WMC, we can carry this step out efficiently and without any errors. However, during peak loads in production, we can quickly help out with Weidmüller's Fast Delivery Service. This means that we can order the terminal strips directly from the WMC at Weidmüller and have them delivered within a few days, already fully assembled. This way, we ensure ourselves a high degree of flexibility and we are able to react quickly and avoid bottlenecks even when production is running at full capacity.

Q: How has the combined power of Eplan and Weidmüller solutions helped you achieve your goal of designing systems faster?

A: By using digital twins and standardised data from the Eplan Data Portal, we significantly reduced the design time. The additional effort involved in creating a digital twin is minimal compared to the traditional approach, mainly thanks to the extensive information we obtain from the Eplan Data Portal. In addition to the commercial data and electrical schematics macros, we also receive valuable technical information such as drilling patterns for mechanical processing and connection diagrams for the wire assembly, which can be integrated directly into the manufacturing process. This has accelerated our production speed by up to 30 percent and has significantly reduced the error rate, as many potential sources of error are already being eliminated in advance through the digitisation.

Another significant advantage comes from our close cooperation with Weidmüller: All digital data for terminal blocks, markers, and labels from Weidmüller is integrated into the Eplan Data Portal, which makes our work much easier. This data flows directly into our design and enables us to work with maximum precision.

A sample project in Eplan Pro Panel

Q: How and where has the collaboration helped in planning the low-voltage main distribution at the Weidmüller plant in Detmold?

A: Projects such as the low-voltage main distribution board in the new Weidmüller plant require a tailor-made approach, as they are no standardised series solutions. Digitalisation has helped us to a great extend in managing the complexity and still achieving a high level of efficiency. Precise planning and the use of digital data from the Eplan Data Portal enable us to deliver customised projects like this one on time and with high quality – even in an environment that constantly presents us with new challenges.

Q: What is it about Eplan data in combination with the Weidmüller Configurator that can offer the ideal basis for electrical planning?

A: Terminals and terminal strips play a central role, especially in the 3D design. Eplan allows us to plan these in detail and with precision. The Weidmüller Configurator complements the whole process by automatically making corrections and ensuring that the labels and markers are correct. In addition, with just a few clicks, we can automatically add other accessories such as end caps or bridges, resulting in an error-free terminal strip. The combination of the two tools optimises our planning and ensures a high reduction in errors during production.

After exporting data from Eplan, the Weidmüller Configurator supports the detailed planning of terminal strips by adding the necessary accessories.

Q: If you had to describe the partnership between Eplan and Weidmüller in just a few words, what would they be?

A: “Partners on equal footing.” For us, these, well they describe a close collaboration in which we support each other. With the helpful solutions and support from Eplan and Weidmüller, we can optimise our processes and provide valuable feedback from inside the field, which also helps both companies to further improve their products.

Comments