Author

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

Profitable Machine Building

Manufacturing companies are increasingly turning to automation to help them retain their competitive edge, which means there is strong demand for machines of all types. But the machines are almost always needed quickly and often have to be designed specifically. How can machine builders respond while maintaining their profitability?

The Current State

In the 21st century, businesses investing in automation have high expectations; they want machines that precisely fit their own specific requirements and they want them now – if not yesterday! This poses a headache for machine builders, because designing custom machines from scratch and even devising the modifications to customise existing machines are time-consuming processes, and there’s always a risk that errors will creep in at the design stage, adding to costs and delaying the delivery of the machine.

And it’s not as if machine design is getting any easier! Today’s component suppliers seem to be upgrading their products and introducing new versions faster than ever, while standards and regulations get more complex and more demanding almost by the hour. In truth, design engineers have a hard time trying to keep up with these developments, let alone handling the pressure for design work to be completed in the shortest time possible.

It’s little wonder that, under these conditions, there’s a significant risk that machine builders will see their profitability fall as they have to foot the bill for overtime payments in the design departments, deal with errors made by designers working under pressure and possibly even compensate their customers for late delivery of their machines.

Looking to the Future

This is a pretty bleak picture – surely there’s something that can be done? There is! The machine builder can take advantage of modern computer aided engineering (CAE) software. But machine builders who go down this route need to be cautious about relying on ideas they may already have about the capabilities and limitations of CAE. The best modern systems have a lot more to offer than is generally realised.

Yes, of course, they allow things like electrical schematics and layout drawings to be produced quickly and efficiently, but where does the information on the components used in those schematics and drawings come from? Not long ago the answer might have been that it came from a rather limited database that was updated once in a while, or even that it had to be entered manually. But now there’s a better way – the Data Portal.

A data portal is an online database of component data, and it’s maintained by the component suppliers themselves who regularly update it to reflect their latest developments. This means that engineers using data from the portal can always be sure that it’s accurate and up to date. Further, in the case of EPLAN, the EPLAN Data Portal database is enormous – it has information on more than 635,000 components from more than 155 manufacturers at present and is growing daily. Needless to say, the data can be directly imported into the CAE software with no need for conversion or manipulation.

Just some of the manufacturers on the EPLAN Data Portal.

Just some of the manufacturers on the EPLAN Data Portal.

The Design Process

The data portal is a big step forward, but what about the design process itself? Well, a good CAE package will allow users to choose the standards relevant to the equipment they’re working on, and will then enforce these standards. They can be national and international standards, but they can just as easily be site standards adopted by the machine builder or imposed by the end customer. Preferred methods of working can also be programmed into the CAE software so that all designs use the same approach, irrespective of which engineer produced them.

But perhaps the biggest time and money saver of all a really good CAE system will deliver is modularisation. This works by breaking jobs down into design modules that can be reused time and time again. For example, a simple module might be a reversing motor starter. When this has been defined as a CAE macro, that work never has to be repeated. All the design engineer needs to do is to call up the macro, and everything else is taken care of automatically.

That’s a very simple example, of course, and most macros will be much more complex. The benefits are enormous. Using these macros for modules saves a lot of time and also ensures uniformity of design, which aids manufacture and maintenance of the machine. Furthermore, once the modules have been tested and proved, they can be reused as often as they’re needed with total confidence that they are error free.

When this modularity is mentioned, machine builders often respond by saying something like, “Ah yes, but our machines are all different, so this doesn’t really apply to us.” Almost invariably they’re wrong! The actual machines may be very different, but if the designs are carefully analysed, it is surprising how many design elements will be found to be common to all of them. EPLAN’s experts have had much experience in identifying these common elements and this experience is at the disposal of existing and prospective customers for the company’s products.

Accurate Documentation

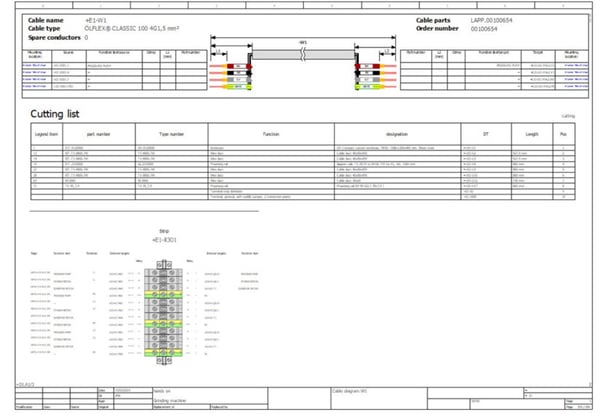

Now let’s look at another area that’s often seen as the bane of designers’ lives: documentation. With conventional engineering approaches, the production of documentation is a tedious and time-consuming job that’s prone to all sorts of mistakes and errors. With a good CAE system, however, the documentation is produced almost at the touch of a button and it’s guaranteed to be accurate. Further, it’s very easy to keep the documentation up to date when design changes are made, and anyone who has ever had to maintain machines on site will know just how big a benefit that is!

Documentation can be created in just a few clicks.

Documentation can be created in just a few clicks.

Choosing the Right CAE Package

So far so good. The CAE package will take in component data from the data portal and, by using macros, it will dramatically reduce the design time needed. It will also make sure relevant standards are observed and it will generate accurate documentation. Can it do more? If it’s a good package, like those that make up the EPLAN platform, the answer is definitely yes.

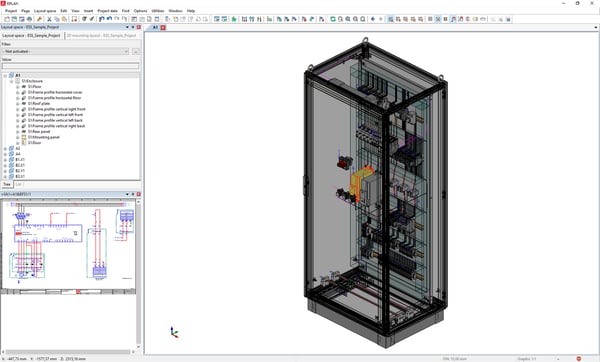

Such a package will provide 3D visualisation for control panel layout and for the placement of components on the machine. It will also show wiring runs and allow them to be optimised. It will produce data in a format that suits the user’s production processes, so that the manufacture of the machine proceeds smoothly and with a minimum of queries. And it will provide similar facilities for fluid power – hydraulics and pneumatics – as well as for the electrical and electromechanical elements of the design.

EPLAN Pro Panel allows design in 3D, which reduces errors as you can see more clearly where components should be placed.

EPLAN Pro Panel allows design in 3D, which reduces errors as you can see more clearly where components should be placed.

In fact, there’s even more that the latest CAE packages can do for machine builders. How about a configurator that allows end customers to fully specify the machines they want in such a way that a quotation can be generated almost instantly and the customer requirements can be imported directly into the design section of the CAE package?

How about easy exchange of data between the CAE package and any other CAD, MRP or similar software that either the end user or the machine builder may use? How about automatic generation of production data that can go straight to CNC machines?

All of these things and many more beside are possible for machine builders that invest in the right CAE software from a dynamic and supportive supplier. There’s no room to explore all of these exciting possibilities here, but the EPLAN team will be very happy to provide further information on request! Hopefully, however, enough has already been said to show that the right CAE package is the key that unlocks the ability of machine builders to respond effectively to present-day market requirements and to do so profitably.

Comments