Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

How To Reduce Errors In Your Manufacturing Process With ECAD Software

Automate Or Eliminate Elements Of Your Design That Are Prone To Error

Pre-empting and reducing the number of ways an error can occur is one of the easiest ways to improve design efficiency. A great electrical design package will help you optimise your designs by reducing the number of manual tasks needed, such as importing parts data, creating a bill of materials and wire routing. Automating these tasks will enable electrical engineers to accurately create complex designs quickly and provide error-free documentation to manufacturing.

To take this a step further, some ECAD software allows you to save and reuse circuits in multiple projects. In the EPLAN world, these are called macros. By using macros, design engineers can be sure that they are not mistakenly copying and pasting the wrong variant or an obsolete component into a project, which may only be uncovered during manufacturing.

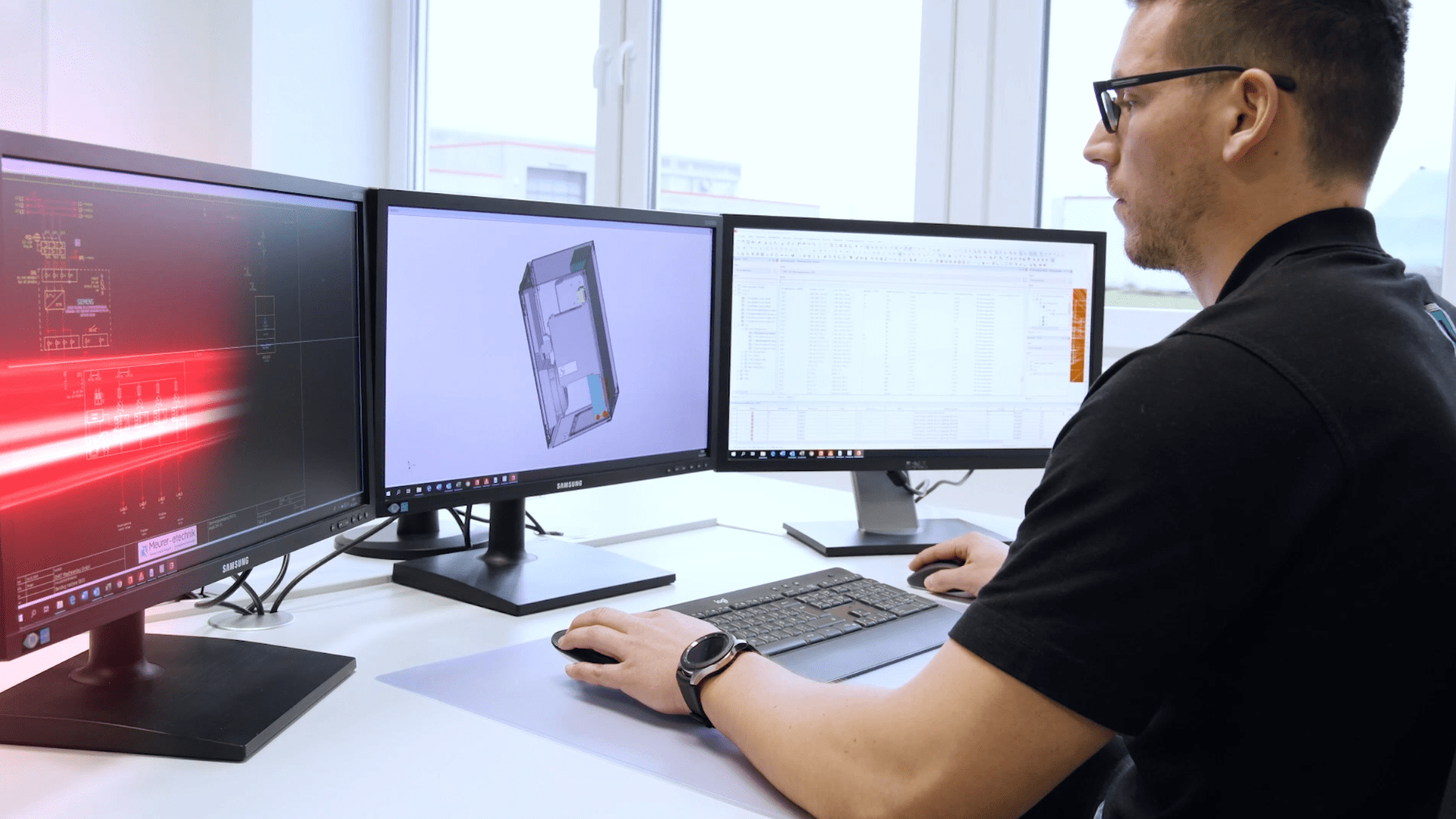

Use 3D Design Solutions

Certain 3D ECAD solutions, such as EPLAN Pro Panel, enable design engineers to evaluate and visualise a digital twin of the electrical control cabinet. This means that they can identify any design flaws e.g., the required components do not fit or that a certain component is blocking a cooling air flow, before implementing changes, continuing with the design and then committing to the manufacturing process. This not only reduces the risk of errors, but also prevents the purchasing department from ordering a cabinet which is too small for its application.

Use Additional Technology To Your Advantage

Whether it’s automating a routine, manual task or using software to carry out audits and checks, new applications are being created every year specifically to make manufacturing simpler and less prone to human error. Technology can even help to fill in the gaps left by those on the higher end of the skill chain – some apps can fill in for workers who have decades of experience under their belt. Instead of allowing employees to make guesses and risk wasting thousands of pounds in lost time and needing to restart a task, let technology guide your team to make better-informed decisions and identify the best paths to take throughout the production process. For example, the EPLAN Smart Mounting and EPLAN Smart Wiring applications provide technicians with step-by-step instructions needed to install mechanical & electro-technical components and wire a control panel without any prior experience.

Understand The Limitations Of The Software You Are Using

If your software is lacking some of the components you are planning to use, designers must manually create them. This leads to an increase in human error as well as higher project overheads. Electrical design software is a great tool, but it has limitations, so it is important to be mindful of the scope of your project and understand the capabilities of your software assets in advance before you begin designing. Electrical engineers should also take extra caution when creating complex designs as there may be certain elements that are not possible to create using your software configuration.

To ensure the best results, electrical design software should be used in conjunction with other engineering tools and processes. Electrical engineers should use their own expertise and knowledge to cross-check their designs, evaluate the risks and potential issues that may arise from using a particular software set up, and make sure their design follows regulations and standards.

Reduce The Amount Of Times Changes Are Made To Wire Numbers

Wire numbers are often automatic until a change is made, and they then revert to manual mode. Reducing the amount of times changes are made to wire numbers, component numbers, and circuits will reduce the chance of problems during the production process. Electrical design software allows you to check your design against a standardised reference library before production begins, ensuring that components are accurately produced and assembled according to their specifications. This eliminates the need for re-work and can save time and money in the long run.

Removing Or Moving A Wired Component

When an engineer needs to reposition or remove a wired component, he or she would normally need to rewire the whole design manually. With modern software, such as EPLAN Smart Wiring, this can be avoided, greatly reducing your time and error margins. Electrical design software can help your engineers quickly and accurately move, reconfigure, or replace wired components in a virtual environment – optimising your designs in minutes without having to manually re-wire each component. This significantly reduces production errors by making sure that all components are correctly placed and wired according to their specifications from the outset, verifying reference designs or checking and updating wire numbers.

Electrical Design UK - What Next?

By using electrical computer-aided design software, you can minimise errors in your manufacturing process and ensure the most efficient and accurate results, making it an essential tool for any electrical engineer looking to optimise their designs and save costs.

With its powerful features that are specific to the electrical engineering discipline, ECAD can create complex designs quickly and accurately while reducing the risk of expensive mistakes. EPLAN is the world’s leading electrical design platform for manufacturers and engineers. To find out more, please call one of our experienced team today on +44 (0)1709 704100.

Comments