Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

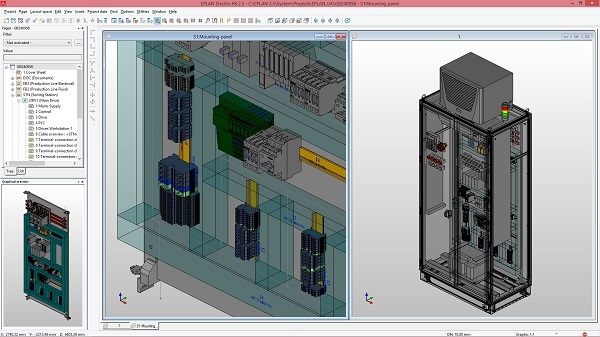

Save Time when Constructing Control Cabinets with a Digital Twin

A digital twin or a virtual prototype is a digital copy of a physical product or object. But how can they help you to engineer faster and smarter?

The first step is to allocate roles. The engineering, arranging and assembly of the control cabinet are all different roles.

- The electrical engineer decides which components go into the cabinet.

- The panel builder organises the layout of the cabinet in detail. This is because of their knowledge and experience.

- The technician implements it.

3D Cabinet Arrangement

The role of the electrical engineer has just got easier, because you can now arrange the cabinet digitally! Instead of laying the components out physically, electrical engineers can now do this in a 3D environment on the computer. This is also known as virtual prototyping or creating a digital twin.

What do you need to be able to virtually prototype?

- Firstly, your design methods need to be connected to your virtual prototype. This is only possible if your schematic is drawn functionally. You can find out how to do this by reading an earlier blog about functional drawings.

- Secondly, your parts database should contain 3D macros of all the components that you use in control.

- Finally, you need the correct module to virtually prototype a control cabinet in 3D.

Once you have completed the above steps, you are ready for virtual prototyping!

Want to discover how you can create a digital twin yourself?

The Advantages of Virtual Prototyping the Control Cabinet's Layout

Virtual prototyping allows the panel designer to design the control cabinets digitally in 3D. This has many advantages:

- Virtual prototyping saves a lot of lengthy, manual work in the cabinet layout.

- You already know if all of the components fit in the cabinet before it’s ordered.

- You know whether you can order the control cabinet in a smaller size, which would save money.

- You can work out if the control cabinet fits where it will be placed.

- The digital twin can be shown to the customer for approval. If the customer would like to make changes, the design can easily be modified without incurring high costs.

- With the correct software, you can automatically route the wiring. Wiring lists can be generated automatically and organised in many ways (e.g. 230V connection). This means that the technician doesn’t have to read complicated schematics and anyone can wire a cabinet after only having brief instructions.

- If you change the position of a component, the wire length is automatically changed in the wiring list, which reduces the errors.

- Drill templates are automatically generated.

- The panel drilling specifications can be sent to control a CNC machine in the workplace or in a specialised business.

Comments