Author

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Graham Bloom

Graham has worked at EPLAN for over 8 years and is a Professional Services Senior Consultant. His background and experience in electrical, mechanical and production engineering mean that he provides excellent service in training and consultancy. Graham works closely with customers to define their optimal solutions based on EPLAN's product portfolio. He also works closely with the pre-sales team to analyse customers' specific requirements and understand their business drives & needs to translate them into a technical solution.

bloom.g@eplan.co.uk

Graham Bloom auf LinkedIn

Software Solutions for Panel Builders

Modern CAE software systems enable manual, time-consuming engineering design functions to be performed automatically and instantaneously. By using a well-chosen system of this type, panel builders can, therefore, benefit from an increase in productivity, shorter project turnaround times and improvements in product quality.

What do you want from a good CAE system?

The best CAE systems are those that continually evolve, improving usability, reducing the amount of manual data entry and error checking, and also facilitating adherence to corporate, national and international standards.

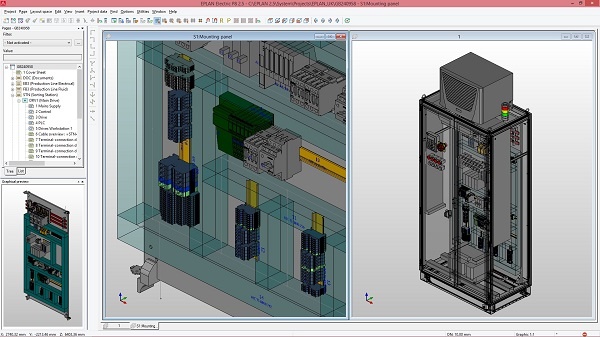

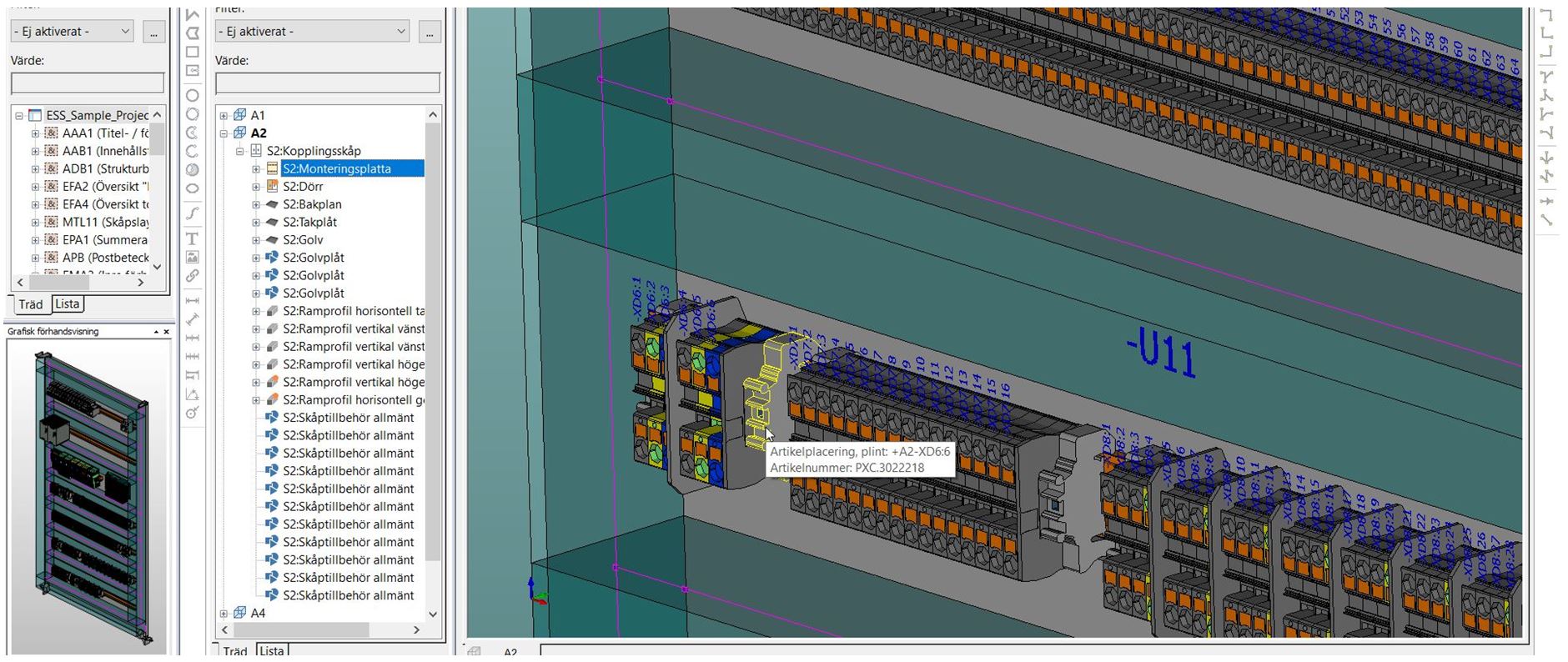

A prime requirement for a CAE solution for the engineering of control cabinets is that it should enable electrical and, where necessary, fluid engineering mounting layouts to be designed rapidly and easily in 3D. It should generate information relating to things like mounting holes and panel cutouts automatically.

Design in 3D with EPLAN Pro Panel and easily see where components should be placed to avoid errors and utilise the space.

Design in 3D with EPLAN Pro Panel and easily see where components should be placed to avoid errors and utilise the space.

Intelligent placement tools that take into account components manufacturers’ specifications will guarantee planning reliability, optimum space utilisation and accurate production information.

The functions for placing and editing components must be supplemented by dynamic collision checks and the online connection displays, allowing users to utilise the often limited available space within the control panel efficiently.

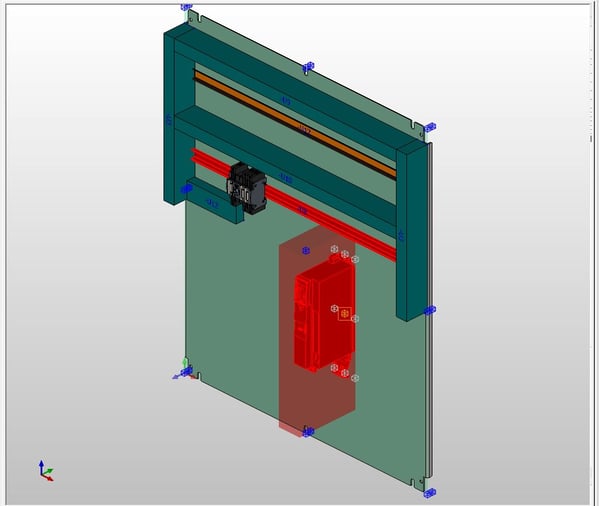

The collision control feature of EPLAN Pro Panel shows you where you can and can't place components, reducing the errors in a project's design.

The collision control feature of EPLAN Pro Panel shows you where you can and can't place components, reducing the errors in a project's design.

When all components, trunking and mounting rails are placed in the design, good CAE software will also automatically check whether the proposed placements meet design requirements such as minimum allowable spacing distances. This saves the engineer valuable time as the need for trial-and-error component positioning is eliminated.

With repetitive data entry and manual data conversion no longer needed, product development can be made more efficient. This frees up engineering time for further innovation. In addition, continual data exchange increases project quality and accelerates the entire engineering process on a sustainable basis.

The best CAE systems for panel building applications use 3D enclosure prototypes and connection information from the circuit diagram to determine optimum wiring distances and routes, as well as the required lengths for all wires and cables within the panel.

Another invaluable feature that should be offered by a CAE solution for panels is the ability to design copper elements such as busbars and risers. This functionality, together with the 3D placement options already discussed, enables engineers to generate an accurate virtual representation of the panel, and to produce all of the manufacturing information needed for it to be built.

Is there more to a good CAE system?

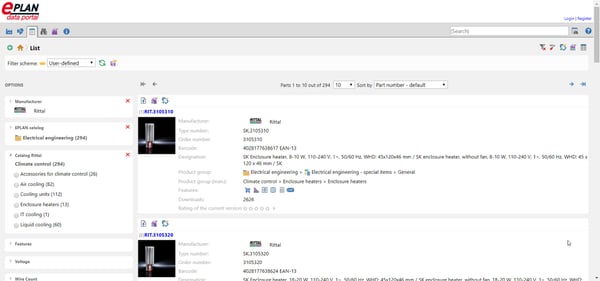

An important but easily overlooked feature is the ability to import comprehensive component information via an online data portal. The information accessible via a portal of this type is regularly updated by component manufacturers, so engineers can always be sure that it is accurate, complete and up to date.

The EPLAN Data Portal is continually being updated by manufacturers with new components for EPLAN users to drag and drop into their project.

The EPLAN Data Portal is continually being updated by manufacturers with new components for EPLAN users to drag and drop into their project.

Using CAE software for control panel design aids the testing process by ensuring uniformity of design approach and execution. It also ensures that specific requirements relating to the mounting and wiring of components are always met and that errors are detected early in the design phase when they can still be corrected easily and inexpensively.

What difference does this make in manufacturing?

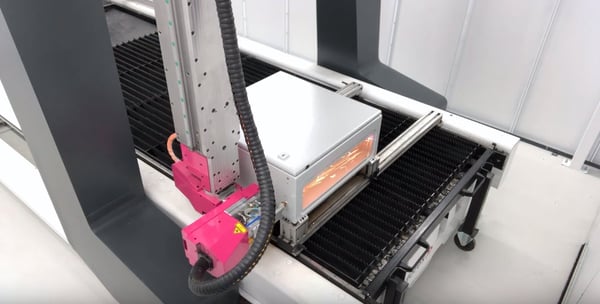

Project reports, schematics, 3D visualisations and dimension information relating to production and mounting can be generated directly by the CAE software, and some packages can go even further. These advanced packages will also generate CNC data required for drilling and punching the enclosure and mounting plates and even, in some cases, the data needed to control an automated wiring robot.

If there are plans to use this type of advanced facility, either immediately or at some time in the future, it is worth checking that the CAE package has flexible data export facilities to ensure the information can be provided in a form that is compatible with the machines and robots that will be used.

Rittal Automation System Perforex machine in action.

Rittal Automation System Perforex machine in action.

What about Codes & Standards?

Integrated support for implementing codes and standards is another feature that should be taken into account when selecting CAE software for panel building applications. Standards compliance is an almost universal requirement among today’s specifiers and purchasers of control panels and it is worth bearing in mind that it’s not only engineering standards that are likely to be important – adherence to the latest standards for drawings and documentation is an increasingly common request.

Reuse

Perhaps the most challenging aspect of engineering design, however, is that no two projects are identical, yet many elements need to be repeated over and over again. This means that the engineer is faced with two options. The first is to simply copy and paste system design elements used in previous projects. Unfortunately, although this may save time in the short run, it’s all too easy to end up copying mistakes and faults, leading to problems during project implementation.

The second option is to create the project design from scratch, with the new data and calculations. This option is, however, time consuming and, although it can lead to improved quality and innovation, it also means that there is little standardisation; every job is different.

By far the best solution to these challenges is to choose a CAE package that allows users to build up their own library of proven design “modules”. These can be as simple as a direct-on-line motor starter or as complex as a complete conveyor control system, depending on the application. Such modules can be reused as often as needed, safe in the knowledge that they have been fully tested and evaluated. This approach not only saves time, it also ensures a high degree of design uniformity, which aids testing and maintenance.

In conclusion, the right CAE solution for panel builders and system integrators is one that minimises design and manufacturing time and costs. It should be a supportive guiding tool that helps bring out the best ideas in engineering design, sifting out mistakes and automating mundane tasks to let ideas flow.

Would you like to know more about the EPLAN CAE software solutions and how it can support you in panel design? Download the white paper.

Comments