Author

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

Nigel Grant

Nigel has been working at EPLAN UK for almost 3 years as an Applications Engineer. His main tasks include installing the EPLAN software, giving live demos to prospects and customers and training customers on best practices for using the software. He has previously worked as an Electrical Engineer and a Project Engineer, both of which have driven his passion for helping companies become more efficient and driving their engineering to the next level. Nigel's experience in panel wiring, electrical engineering and project work has given him a well-rounded view of the industry. This enables him to offer customers the best solutions for their processes.

grant.n@eplan.co.uk

The right tool for the job: CAD or CAE?

What is CAD?

CAD design software was originally developed for mechanical design work. Modern packages are excellent if you want to produce 2D and 3D drawings of mechanical components, and they will save you a lot of time compared with producing similar drawings by traditional manual methods. You can draw almost anything with a good CAD design software, including electrical schematics so, if you’ve never used a CAE system, you may well be convinced that CAD is all you need. And that’s true if you don’t mind missing out on a whole range of benefits that can hugely improve your productivity and profitability.

How does CAE differ?

So what exactly is it that CAE can give you that CAD can’t? In a nutshell, it can automate up to 90% of the electrical design process. That’s a big claim, so let’s look at it in a bit more detail. Among the simplest but most useful things a CAE system does is to take care of tedious and time-consuming tasks like wire numbering, the production of terminal schedules and bills of materials. This frees up your designers to concentrate on the more creative aspects of their work. The video below shows how quick wire numbering is with EPLAN P8.

Repeatedly use your tested and proved macros

But CAE can do so much more. It can enforce design rules, whether they’re product related, needed to ensure standards compliance, or requirements imposed by the end customer. A good CAE system will also allow you to develop standardised design blocks for commonly used functions like motor starting and duty-standby arrangements. EPLAN refers to blocks as macros.

Once they’ve been developed, these macros can be reused as often as needed with the CAE system automatically taking care of all the details like wire and component numbering and cross-referencing. Not only does this dramatically reduce design time, it also ensures a high level of uniformity which makes equipment easier to build and maintain. Furthermore, once the design of a macro has been tested and proved, it will be right every time it is reused, which means big time savings during test and commissioning.

Say goodbye to paper drawings!

A good CAE system will also make it easy for you to eliminate paper drawings, delivering information to your shop floor and, if you wish, your customers in digital form for viewing on a tablet or computer. This means that everyone is always working with the very latest information – there are no paper copies floating around that were printed before the last two or three revisions were made, just waiting to cause chaos and confusion.

And, if it’s well implemented, digital document delivery has an additional big benefit: it provides a convenient and effective way of sending information back to the design team about modifications made on the shop floor or on site. It’s common knowledge that, when paper is being used, ‘marked up drawings’ all too often get lost, which means that the master drawings never get updated. With digital document delivery, this problem disappears.

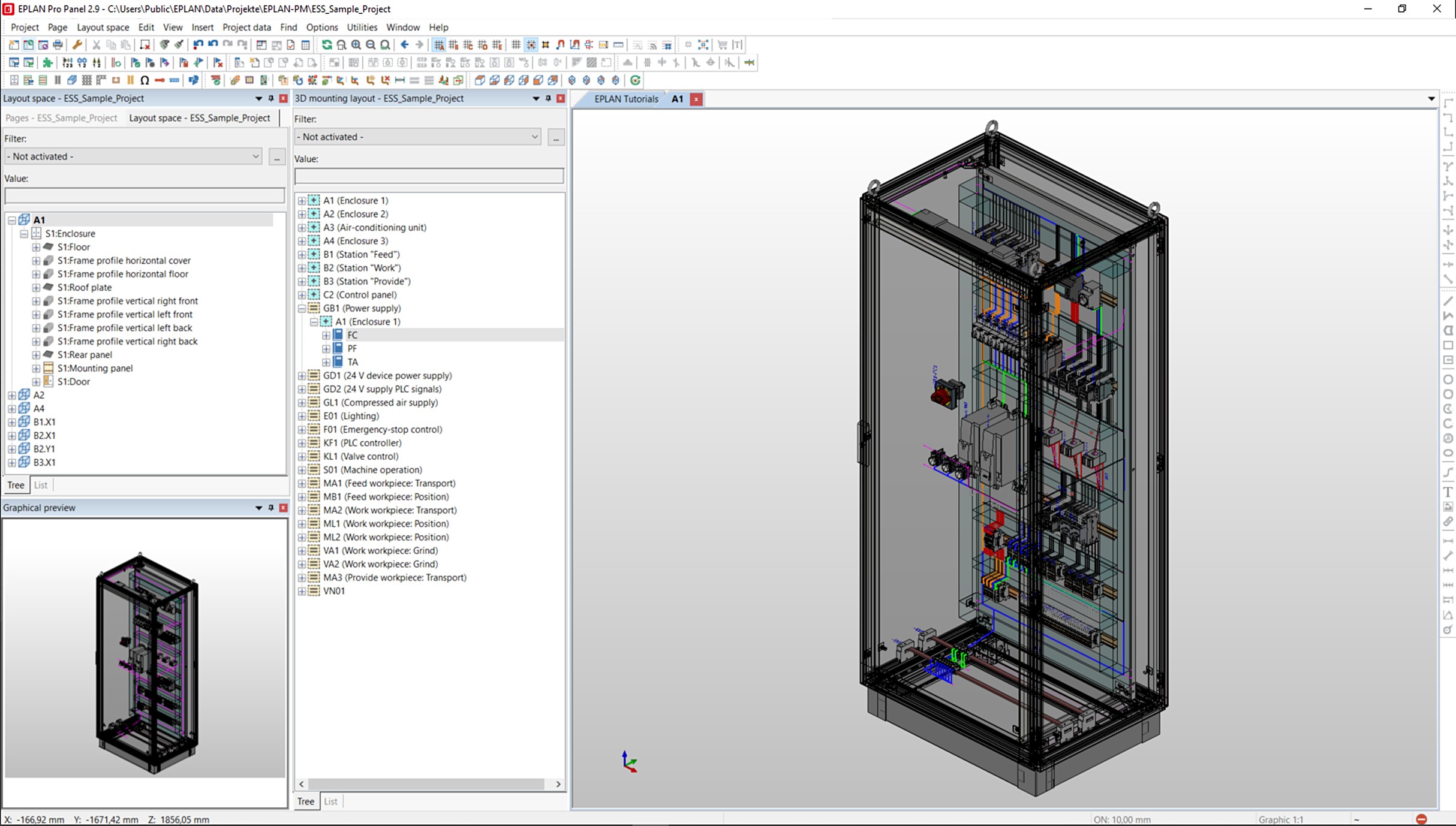

Digital twins are the future of efficient engineering.

Another very interesting option offered by state-of-the-art CAE systems is the ability to create ‘digital twins’. This is a virtual representation of, for example, a control panel which can be examined for errors before work commences on the real thing. This means problems that would be costly and time consuming to put right if they were discovered on the shop floor during manufacturing can be easily corrected, often with no more than a few mouse clicks. The potential for reducing costs and eliminating delays is enormous.

A digital twin of a control panel in EPLAN Pro Panel.

CAE also supports automated production.

Finally, for those users engaged in large-scale production, it’s worth noting that the best CAE systems will generate data that can be directly used by automated production machinery. This includes laser machining centres for adding cut outs to enclosures and wiring machines that cut to length all of the wires needed in a control panel while also printing the wire makers.

Points to consider when choosing the right CAE for your needs.

When it comes to electrical design, it’s clear that CAE systems have more to offer than CAD systems, but surely there must be factors that weigh against them? One of the them is that to get the best out of a CAE system, good operator training is needed, so it’s important to choose a supplier that provides this and to factor training costs into the implementation budget. It’s also crucial to work with a supplier that will provide the support that may be needed to formulate the rules and templates to be used by the new system.

A further factor to be considered is that the results obtained from even the best CAE system will be no better than the data that’s fed into it. This is actually much less of a concern than it might at first appear, especially for EPLAN users, as the EPLAN Data Portal contains information on millions of components from hundreds of suppliers. This data is maintained by the component manufacturers themselves and is always up to date. It can be accessed free of charge and is presented in a format that’s directly compatible with good CAE software.

Some of the manufacturers in the EPLAN Data Portal.

Conclusion

In conclusion, there’s nothing wrong with CAD design software if your main interest is in mechanical engineering or if you merely want to make it easier for your designers to produce good looking drawings. But if you want to streamline and automate your electrical design processes to reduce costs, save time, boost profits and improve your product quality, CAE has to be the way to go. You’ll need to invest some money and a little time, but you can be sure of an outstanding return on your investment.

Why not see all these benefits for yourself? EPLAN will be pleased to arrange a no-obligation free-of-charge demonstration of its market leading CAE systems and to discuss with you the challenges and aspirations of your business. Take the first step and click the below button.

Comments