Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

What is Automated Engineering and Why Is It Important?

Automated engineering is the process by which software automates repetitive design tasks, such as generating electrical schematics and documentation. This leads to more efficient and effective engineering of a wide range of equipment, machines, and tools.

Key Technologies for Automated Engineering

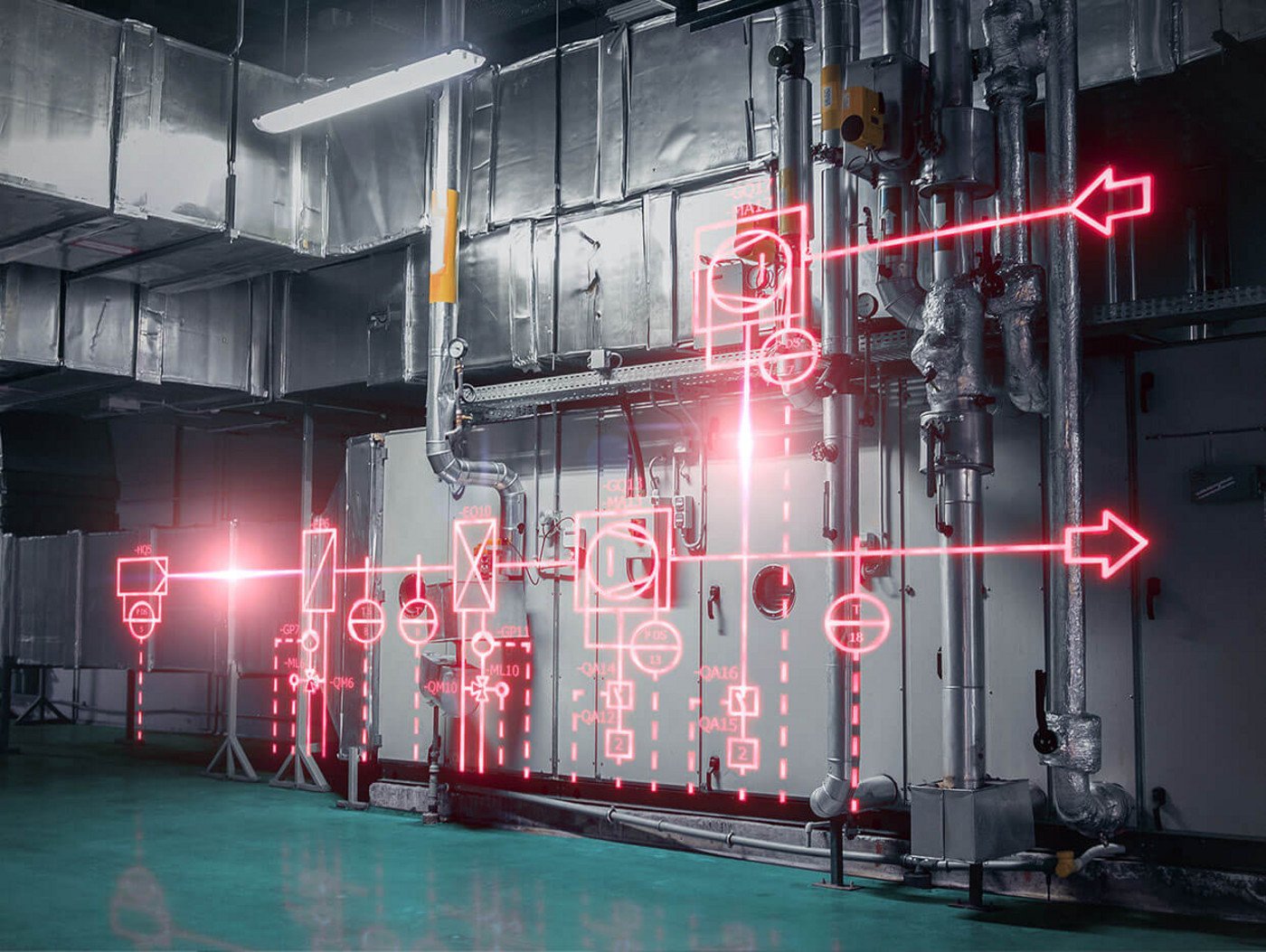

Software solutions widely used in automating engineering work include Eplan Engineering Configuration (EEC) . With EEC, organisations can automate the creation of electrical schematics and circuit diagrams, 3D control cabinets, and documentation. This provides standardised output for subsequent engineering steps, such as panel board construction.

Benefits of Automated Engineering

Automated engineering automates time-consuming, manual tasks, allowing the design process to become significantly more accurate and efficient. For example, Eplan reduced the engineering process for standard conveyor belts from two weeks to just five minutes at a logistics systems manufacturer, which also brings significant cost benefits. Besides up to 80% faster time-to-market, automated engineering drastically reduces manual errors. Engineers need to perform far fewer routine, copy-and-paste tasks when creating schematics and documentation. This increased accuracy ultimately leads to higher quality end products.

Want to find out more?Read how Eplan implemented automated engineering at this logistics systems manufacturer.

Automated Engineering as a Solution for Staff Shortages

Another advantage of automated engineering? It makes engineers' work much more enjoyable. Automated engineering takes over repetitive tasks, freeing up engineers for tasks that require human brainpower, such as R&D. Indirectly, automated engineering also offers a solution to the shortage of technical personnel. The knowledge of experienced engineers is now stored in the software, preventing it from leaking out of the organisation when experienced engineers leave. Moreover, newcomers can start work sooner, as they no longer need extensive electrical engineering experience and knowledge of the client's organization to generate electrical schematics. And last but not least, because many engineering tasks are automated, organisations can do significantly more electrical work with the same number of staff.

The Role of Automation in Various Sectors

Automated engineering is interesting for companies in a wide range of sectors, from healthcare to high-tech industry and from the food industry to logistics and transport. It offers advantages for any organisation that wants to reduce process costs while simultaneously improving productivity and product quality. One sector that stands to gain significantly from automated engineering is mechanical engineering and industrial automation.

Automated engineering also offers significant benefits for the energy sector, for example, in the design of installations and infrastructure. This sector is facing the challenge of facilitating the energy transition, while the number of available technicians is declining. Automated engineering offers the solution. This allows energy companies to perform more electrical engineering work with less skilled personnel. Read what Eplan can do for the energy sector.

Challenges on Implementing Automated Engineering

Integrating automated engineering into existing processes and platforms can present challenges. A potential solution is automated engineering software like EEC. One organisation that avoids integration problems with this approach is Eaton. This manufacturer of power distribution, switching, and control equipment has managed to automate all human actions in the schematic generation process. Furthermore, Eaton has standardised the output of automated schematic generation to such an extent that EEC can largely automate the subsequent panel building process.

Another challenge in transitioning to automated engineering is that engineers' work changes, requiring additional skills. For example, electrical engineers in automated engineering must collaborate more interdisciplinary, including with mechanical engineers and software developers, which requires excellent communication skills. They also need to develop a more conceptual mindset, enabling them to transcend the technical solution and see the bigger picture. Basic knowledge of mechanical engineering and software development is therefore a plus.

Step-by-step Plan for Implementing Automated Engineering

How do you implement automated engineering? To a certain extent, it's a customised approach. However, there are some implementation steps and best practices that apply to every organisation. Start by identifying the processes and process steps that are repeatable, since this is where automated engineering can encourage the greatest efficiency gains. Then, assess the extent to which these steps are already standardised and standardise them further where possible; after all, without standardisation, there's no automation. Then, launch automated engineering and monitor the time savings.

You can potentially accelerate this by streamlining and standardizing the processes that provide input for schematic generation and documentation creation prior to implementation. For example, by having the input for automated engineering generated by a sales configurator, where the sales department or customer can submit their requirements within standardised frameworks. The next and final step in implementing automated engineering is user training. When engineers know how to get the most out of the schematic generation software, the efficiency gains you achieve with automated engineering are greatest.

Comments