Author

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

What's New in Platform 2025: Reducing Workload for Skilled Workers

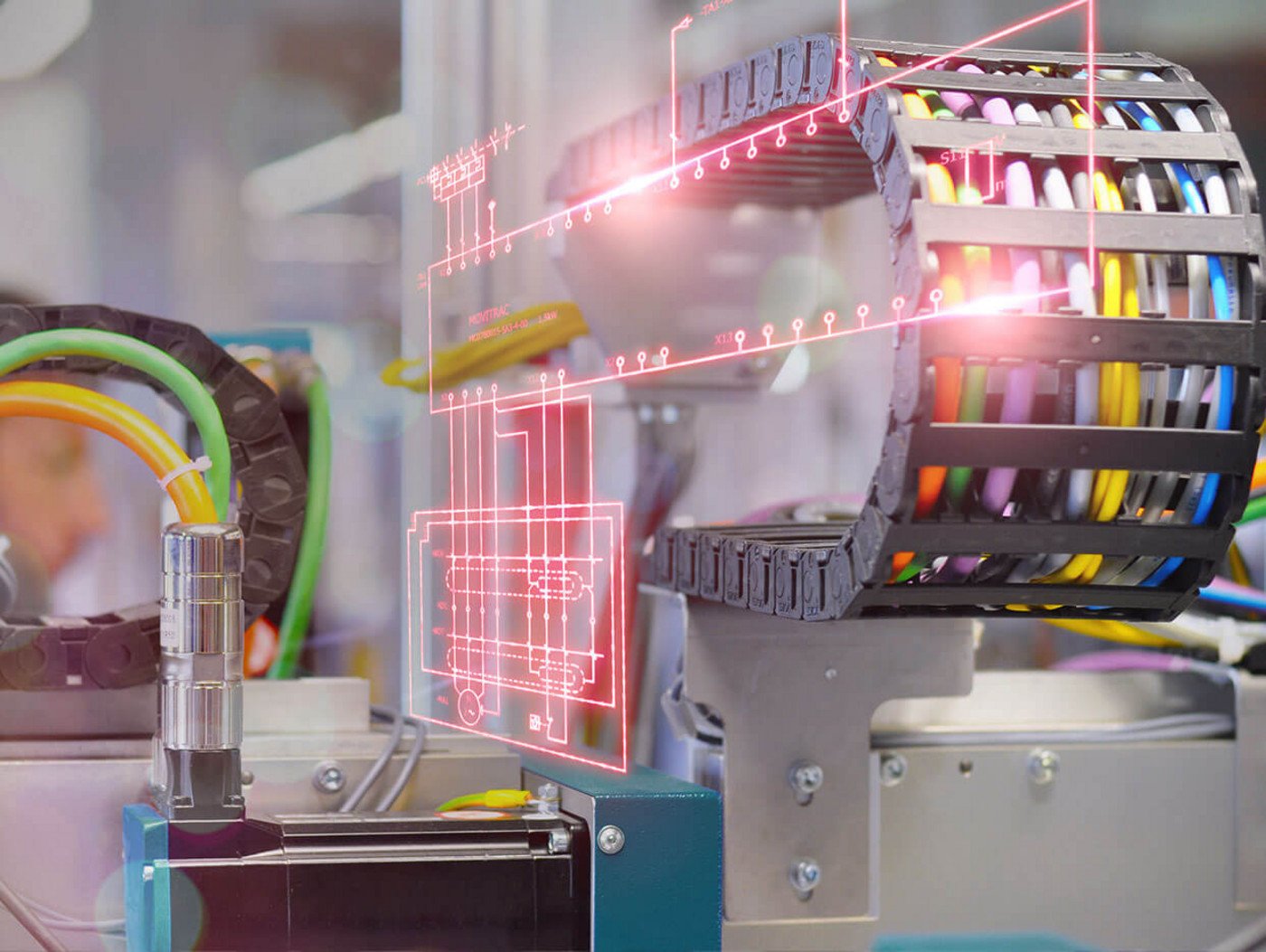

The news is out; Eplan's Platform 2025 is up and running. This update provides more relevant information included in clearer circuit diagrams. Clarified designs allow departments to act quicker, which is better for everybody involved. Today we'll be focusing on reducing the workload for skilled staff.

The new Eplan Platform 2025 supports electrical designers in creating circuit diagrams with updates on ease of use and efficiency. However, circuit diagrams must still be understandable for the end users in production and service. The current Eplan platform offers support to designers in creating meaningful yet accessible circuit diagrams.

In this blog post, we will focus on two of the new functions featured in Eplan Platform 2025: improvement to the depth of information in your circuit diagrams, and improvements to readability. Both functions benefit employees in production and service.

Linking Circuit Diagram Symbols with QR Codes and Images

Electrical circuit diagrams are populated by hundreds of symbols, marks, and circuits. The more complex the machine or plant, the more complex the circuit diagram. These connections may not be legible for less experienced users of the platform, which can slow down overall production processes.

The new Eplan platform offers the option of enriching circuit diagrams with additional information, making them easier and quicker for end users to understand. This involves context-related images of QR codes that can be linked to the symbols and placed directly on them. The manufacturer can then quickly recognise which component is involved and can carry out the correct actions quickly and accurately.

Experienced Eplan designers will rightly point out that adding images to the circuit diagram was already possible in the past. However, the image and symbol are now linked, which means that the image automatically adapts when the component changes and no longer needs to be replaced manually. For example, if a cable is replaced in the circuit diagram, the image for the cable is also updated. If the designer moves the cable to a new position, the image will also update.

QR Codes Take Service Staff Directly to the Information They Need

In addition to placing images on circuit diagram symbols, the latest version of Eplan gives designers the option of linking QR codes to symbols. The codes can be used to link additional information or documents directly to the circuit diagram. The comprehensive data collected through this approach also benefits the end users of the plans.

By enabling quick access to installation instructions or maintenance information, manufacturers and service staff can obtain the details they need without wasting time searching across various documentation. Having the relevant technical information readily available allows users to efficiently complete tasks and address any customer needs.

Complex tasks can be completed in less time, particularly in the areas of maintenance and machine and system service, where downtimes must be kept to a minimum.

In Eplan version 2025, electrical circuit diagrams can be enriched with additional information such as images and QR codes, which benefits end users in production or service.

Immediately Recognise Connections between Components and Wires in Production: Mechanical Wire Feed-through

In production, details matter. Seemingly trivial errors or misunderstandings often lead to costly delays and correction loops. A common example involves components like current transformers or measuring devices that require wiring passage. With Eplan Electric P8 software, the circuit diagram may accurately show the connection between such a device and wires.

However, the interdependency between these elements within the associated connection or wiring list would not be explicitly evident. Without years of experience, it may have been difficult to notice if a particular wire and device belonged together. Because of this, the potential for error was high, and the wire may be overlooked when installing a component.

The mechanical wire feed-through is also available in the control cabinet layout with Eplan ProPanel. The software automatically recognises the dependency between the component and the wire and routes the cable automatically through the component via two connection points. In the connection list generated by Electric P8, the dependency is displayed as 'Mechanical Feed-Through Device'. This means the advantage of increased safety when working with connection lists also applies to control panel designs.

Dependencies between devices such as current transformers or measuring devices and wires are automatically recognised in Eplan Platform 2025 and displayed in connection lists.

Get to Know These Functions with eLearning

For the mechanical wire feed-through and the new function for linking images and QR codes with symbols, free eLearning videos are available after registration at www.eplan.co.uk. The new functions are described in detail in the interactive learning modules and can be tried out at your own pace.

Platform 2025 Update Training Days

The EPLAN Training Academy offers a range of basic, advanced and method training courses on all of our Platform 2025 solutions, including Electric P8, Pro Panel, Harness ProD, Fluid and more. All of these courses take place virtually so you can attend the sessions at home or in the office.

In our two-day update training, you will get to know the important new features and feel confident navigating the update. We will also provide you with more useful tips and tricks for your daily engineering work.

Don't forget to frequently check our Training Dates page to book onto our upcoming courses.

To get started, download the new Eplan Platform 2025 below!

Comments