Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

Why you should work with a Digital Twin

Building a control panel usually takes a lot of time on the shop floor - from ordering the components, determining drill holes, positioning components, cut and install wiring - all this requires the utmost precision and craftmanship. How can this be done smarter, and faster?

Divide the roles

The first step is a good division of roles. The engineering, layout and assembly of the panel consists of various roles:

- The electrical engineer determines which components will be placed in the cabinet.

- The panel designer (cabinet designer) determines the cabinet layout in detail. Due to his knowledge and experience, it is obvious that the panel builder takes on this role. 3D design is therefore not a threat to the panel builder, but an opportunity to grow into a role as an engineer.

- The technician will build the panel.

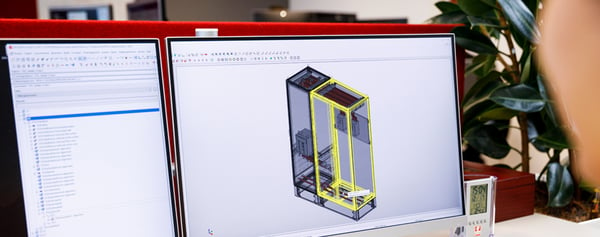

3D cabinet layout

Let's focus on the role of the panel designer as we are going to digitalise arranging the panel. Instead of physically distributing the components, the designer does this in a 3D environment on the computer. This is called virtual prototyping / digital twin.

What do you need for virtual prototyping?

- Your design methodology must connect seamlessly with virtual prototyping. This means that you preferably draw your diagrams function-oriented.

- Secondly, your article database must contain 3D macros of all components that you use in the control.

- Finally, you need the right software module for 3D prototyping of the enclosure structure.

If so, you are ready for virtual prototyping.

The advantages of virtual prototyping of the enclosure layout

Virtual prototyping enables the cabinet designer to digitally design the control cabinet structure in 3D, in advance. This offers many advantages:

- Cabinet layout with virtual prototyping saves a lot of time-consuming, manual work.

- Even before the cabinet is ordered, we know whether all components fit in it.

- For example, you can order a smaller switch box, which in turn saves money.

- Or do the switch boxes fit in the room where they are placed?

- You can submit the virtual prototype to the customer for approval. The design can still be easily changed without high costs.

- With the appropriate software, the system can automatically determine the routing of the wiring. Wiring lists are automatically generated voltage-oriented (eg 230V interconnects). This way, the technician no longer has to read complicated diagrams and everyone can wire cabinets after a short instruction.

- A change of position of a part can be written back to the schematic and a new wiring list is generated.

- Drilling templates are also automatically generated.

- Or better yet, the system can automatically control a CNC machine, like the Rittal Perforex machine. Alternatively, there are specialised companies who can assist, such as LCA Group.

Comments