Author

Barry Chatham

Barry is a Business Consultant for EPLAN UK, working closely with the commercial team and a facilitator to the technical team in ensuring that EPLAN are delivering the right value at the right time to our customers.

Having graduated as an Industrial Designer and being deeply immersed in a wide range of disciplines, the learning curve in each of Barry's roles has been vast. This brings with it a wealth of experience, something demonstrable from recent years in CAD software such as Siemens PLM and more recently SolidWorks, where starting in technical and moving into commercial roles, Barry has successfully assisted hundreds of companies through transitional change and added value not only to his customers but heavily focusing on their customers and delivering results in dozens of different industries.

Having been asked the question years ago at an interview, it changed his outlook and discussions on the manufacturing industry, the question was "I make scissors in Sheffield as a consultant, I want you to make me more money"...

This question, and the "so what" methodology enabled Barry to see from a different perspective, something which is proving to be very well received with some of our customers already.

Chatham.b@eplan.co.uk

Barry Chatham auf LinkedIn

Barry Chatham

Barry is a Business Consultant for EPLAN UK, working closely with the commercial team and a facilitator to the technical team in ensuring that EPLAN are delivering the right value at the right time to our customers.

Having graduated as an Industrial Designer and being deeply immersed in a wide range of disciplines, the learning curve in each of Barry's roles has been vast. This brings with it a wealth of experience, something demonstrable from recent years in CAD software such as Siemens PLM and more recently SolidWorks, where starting in technical and moving into commercial roles, Barry has successfully assisted hundreds of companies through transitional change and added value not only to his customers but heavily focusing on their customers and delivering results in dozens of different industries.

Having been asked the question years ago at an interview, it changed his outlook and discussions on the manufacturing industry, the question was "I make scissors in Sheffield as a consultant, I want you to make me more money"...

This question, and the "so what" methodology enabled Barry to see from a different perspective, something which is proving to be very well received with some of our customers already.

Chatham.b@eplan.co.uk

Barry Chatham auf LinkedIn

How to Break Down the Wall between Engineering and Production with 3D

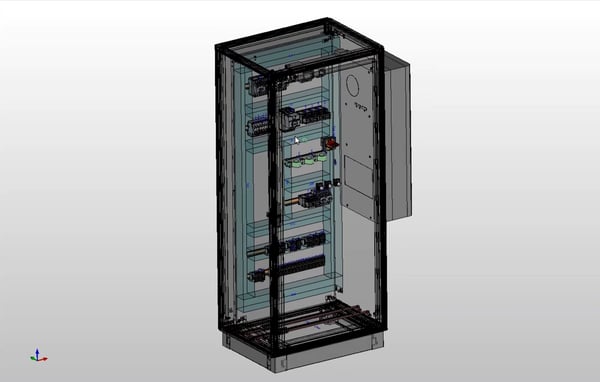

Designing a cabinet as a 3D computer model by drag and drop is also called virtual prototyping. Visual representations (digital twins) of the suppliers' physical components are used. 2D views are generated from the 3D environment. The person who builds the physical panel can see how the engineer came up with it, preventing any unnecessary questions. Even before any holes have been drilled, working in 3D makes it possible to open the enclosure door and identify and solve any problems.

Efficient Handling of Last-minute Changes

Last minute changes may be required if a customer (unexpectedly) sends comments back at the last minute or wants to implement additional elements. It can even happen

when engineers have already completed the project and production is ready. When working in 3D, the engineer immediately sees whether there is sufficient time and/or physical possibilities to adjust the panel to meet the last-minute wishes. He can easily edit previously entered data and quickly gain insight into the level of adjustments that need to be made.

This means that the project can still be forwarded to production without any problems. When it comes to last-minute changes, you make an efficiency boost by building a 3D project. Of course, any mechanical changes to, for example, the enclosure door must be possible without the need for a completely new panel.

3D enclosure in EPLAN Pro Panel

3D enclosure in EPLAN Pro Panel

Free Data Flow

Designing in 3D helps to break the program structure within the entire panel building process. Pen is no longer needed and data can be opened, enriched or improved at any time and saved again. This free data flow requires a new, digital-first vision within the organization.

It is of the utmost importance that the different departments reinforce each other based on this vision by ensuring that the as-build version is an exact version of what engineering has agreed with the customer. Any improvements in the assembly must always be processed immediately in the drawings and diagrams.

Deploy Staff More Efficiently

Traditional panel construction is highly dependent on technical personnel, but technical people are increasingly difficult to find. Thanks to applications such as Smart Wiring and Thermal Design, but also with standard engineering programs such as Therm and Clip-Project, design errors can already be detected during engineering.

The physical manufacturability is already tested when using 3D applications. As a result, less technically skilled colleagues can use the (digitally) supplied documentation to quickly see how the panel must be assembled and wired. The choices made are therefore also easier to understand.

Save Time with Smart Wiring

Wiring is the most time-consuming job. It takes on average 49 percent of the total production time and requires well-trained technicians. Thanks to Smart Wiring, a program that provides step-by-step instructions, wiring work can also be done by people without specific prior knowledge. Think of self-employed people who do not come from a technical sector and who form a 'flexible layer' for organisations during production peaks.

Thanks to Smart Wiring, maximum digital wiring support is also provided from your digital design. This means that wiring data from engineering can be copied one-on-one, without a media break, the associated error probability, and interpreted by wire-making machines.

EPLAN Smart Wiring

EPLAN Smart Wiring

Thermal Design and Rittal Therm

Critical components must not get too hot. Right from the start, Rittal Therm helps engineers to choose the right and most energy-efficient cooling system solution. With just a simple click, it makes a complex calculation based on the data from the EPLAN Pro Panel, with which potential overheating is detected in time.

Thermal Design helps to place these climate control components optimally. Areas that are too hot - hotspots - are prevented because designers are warned about this in advance. This allows the components to be positioned correctly and within the reach of a cold air stream.

The benefits of 3D design:

- Easily implement last-minute changes

- Report design errors on time and automatically

- Create one data flow for engineering and production

- Deploy technical staff more efficiently

- Make the best use of Smart Wiring, Thermal Design and Rittal Therm

Do you want to know more about how you can break the wall between engineering and production with 3D? Read the white paper ' Control Cabinet Manufacturing 4.0'

Comments