Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

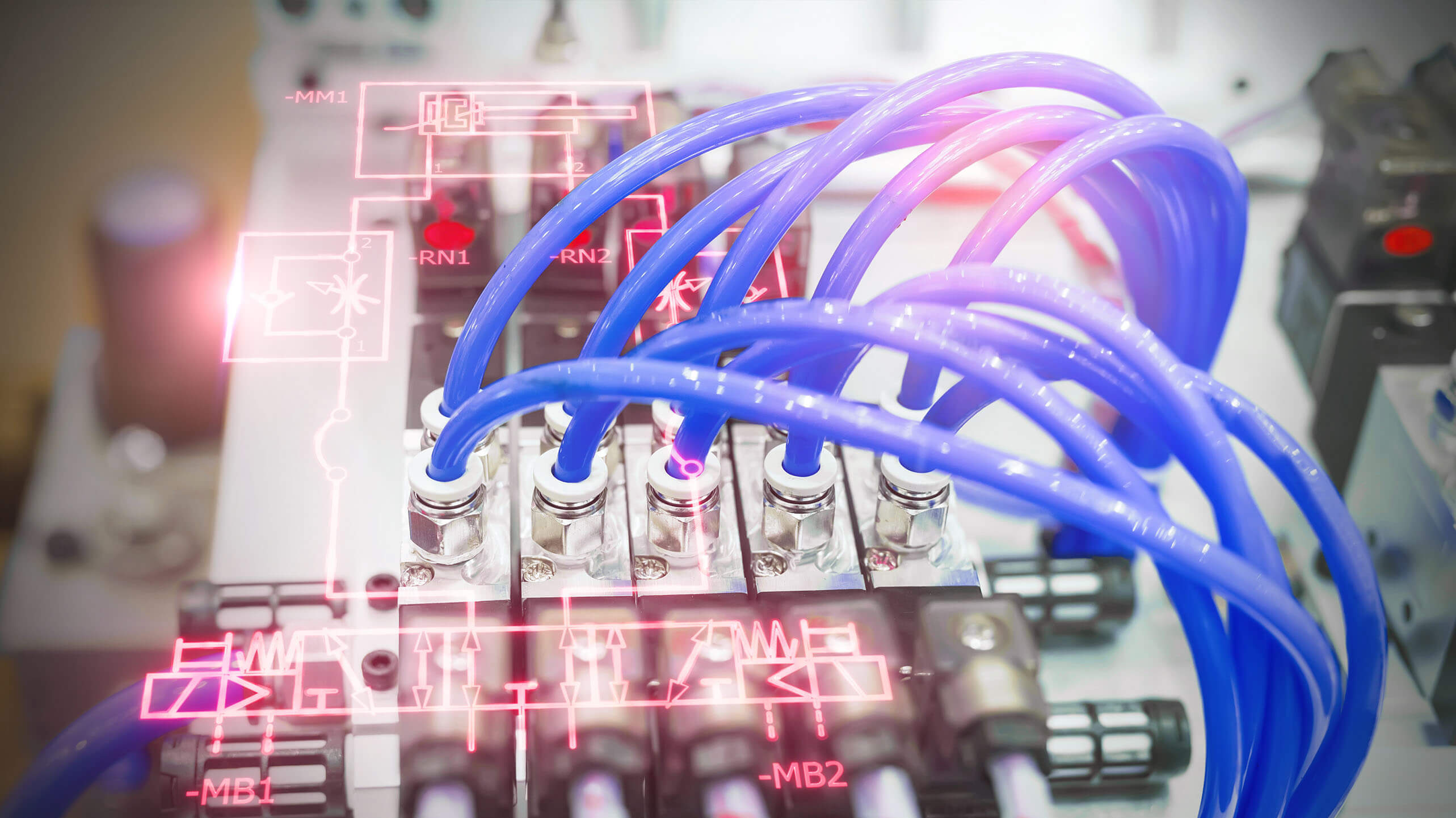

Can Integrated Software Improve Fluid Power Engineering?

Among other benefits, integrated software can improve design times and consolidate material procurement processes. EPLAN brings fluid power engineering and electrical engineering together in one multi-disciplinary solution, which is of particular benefit to machine manufacturers and OEMs.

1) Continuous integration

The term continuous integration derives from software development. Continuous integration in software engineering entails the regular synthesis of different software components into a common base at all stages of the development process. It aids collaboration and lessens the risk of incompatibilities at later phases of projects.

When developing fluid power engineering systems with cross-dependencies, the concept is broadly similar. Continuous integration enables the fast and accurate design of fluid power systems with full cross-references to electrical control components. Integrated software such as this includes 3D models to map the full system closely. Developed in this way, engineers work together on one coherent project, with no need for periodic information transfer.

2) Reduced costs and time-to-market

Integrated software allows engineers to identify issues at earlier phases of the design and development process, preventing them from becoming major incompatibilities further down the line. Such incompatibilities often require lengthy design revisions or reworks and can be a major cause of project overruns. Better yet, the collaborative effects of a multi-disciplinary approach may even prevent such issues from arising in the first place, leading to more efficient and reliable systems.

3) Simplified billing

A basic but costly problem for non-integrated engineering systems is inconsistent procurement. Integrated software enables users to keep track of component procurement and provides a single bill of materials. Duplicate component orders are thereby prevented, lowering costs and wastage.

4) Improved design

EPLAN's integration software enhances the development of fluid power engineering systems with collaborative design tools. By incorporating multi-disciplinary solutions, the software promotes faster, more accurate and cost-effective system design.

In particular, EPLAN Macro Technology provides utilities for design standardisation, allowing the reuse of tried and tested common design patterns to save time and effort and ensure consistency and reliability across projects.

What next?

Get in touch today to find out more about the intersection of electrical engineering with fluid power systems and how EPLAN can help facilitate continuous integration in software engineering.

Comments