Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Do you want to finish work on time? Avoid Duplication!

In my time as a project engineer and panel designer, I have made my share of mistakes. I have worked a lot of overtime, which meant working through the weekend. On the one hand, I had a nice additional wage, on the other hand, however, I was often away from home and had less time for my family. Can you relate to this?

I regularly meet a lot of engineers who are stuck in the same rut that I was in, and they ask me the same questions:

- How can I meet tight deadlines?

- How can I avoid duplication and errors?

- How can I work more efficiently?

So, what's the solution? I have found that by introducing structuring into electrical design, I can save time, which ultimately means that I can get home to my family!

Are you now thinking "how do you do this?" Keep reading..

Your Gateway to Greater Efficiency - "8 Fields of Action"

Based on feedback from over 45,000 customers from over 50 countries around the world from a variety of industries, we have identified 8 areas in which you can make changes and/or improvements which ultimately leads to an increased and flexible engineering process. We have called them "8 Fields of Action", and they are:

- IT Infrastructure

- Platform Setup

- Codes & Standards

- Product Structure

- Design Methods

- Workflow

- Process integration

- Project Management

In this blog, I'd like to dig deeper into two fields of action that I use every day, because they can save you a lot of time! They are Codes & Standards and Design Methods.

Codes & Standards

For the machines and installations you design, there are countless, often legally binding standards and guidelines for the documentation and production. It is easier to comply with these standards and guidelines by incorporating them into your system, design methods and processes.

In addition, you create an excellent base for storing your own guidelines and standards. To engineer more efficiently, you have to ask yourself "where am I duplicating effort?", "which elements of a project can I reuse?". The solution is STANDARDISATION.

Now, I know what you are thinking, just another buzz word: standardisation is doing everything according to protocol, the killer of creativity. But it's not! No, standardisation is actually something that we already do: reuse schematics, but structure them to ensure less chance of mistakes. Standardisation is the structuring of products into reusable modules and establishing clear definitions so that engineers from different disciplines speak the same language. The standard IEC 81346 is a good base for such structuring.

What does structuring mean exactly? If, for example, your internet modem is broken, the technician needs to know where to find it. A good structure to establish this could be postcode, house number, room (for example, living room), modem number. With this information, the technician knows exactly where he needs to be. It is the same with engineering. By using structuring, based on IEC 81346, a technician can trace and replace a broken part quicker. Additionally, the other engineers, the workshop, and the panel builder cooperate better.

By bringing structuring into your design, you save both time and money. It is important because the simplest way of saving time is often ignored and every project is started from scratch. You save more time by storing your engineering knowledge in modules, which allows you to complete additional tasks.

Design Methods

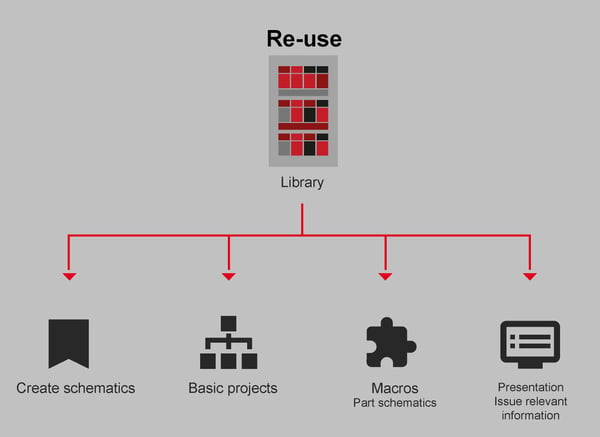

The design method must integrate into the standardisation programme to make your engineering more efficient. For this to happen, functional design must replace the traditional method of drawing in order to design quicker. We can finish the project faster by constructing the project with pre-defined macros from the library. Functional drawing also enables changes to be made more quickly and simpler.

Comments