Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

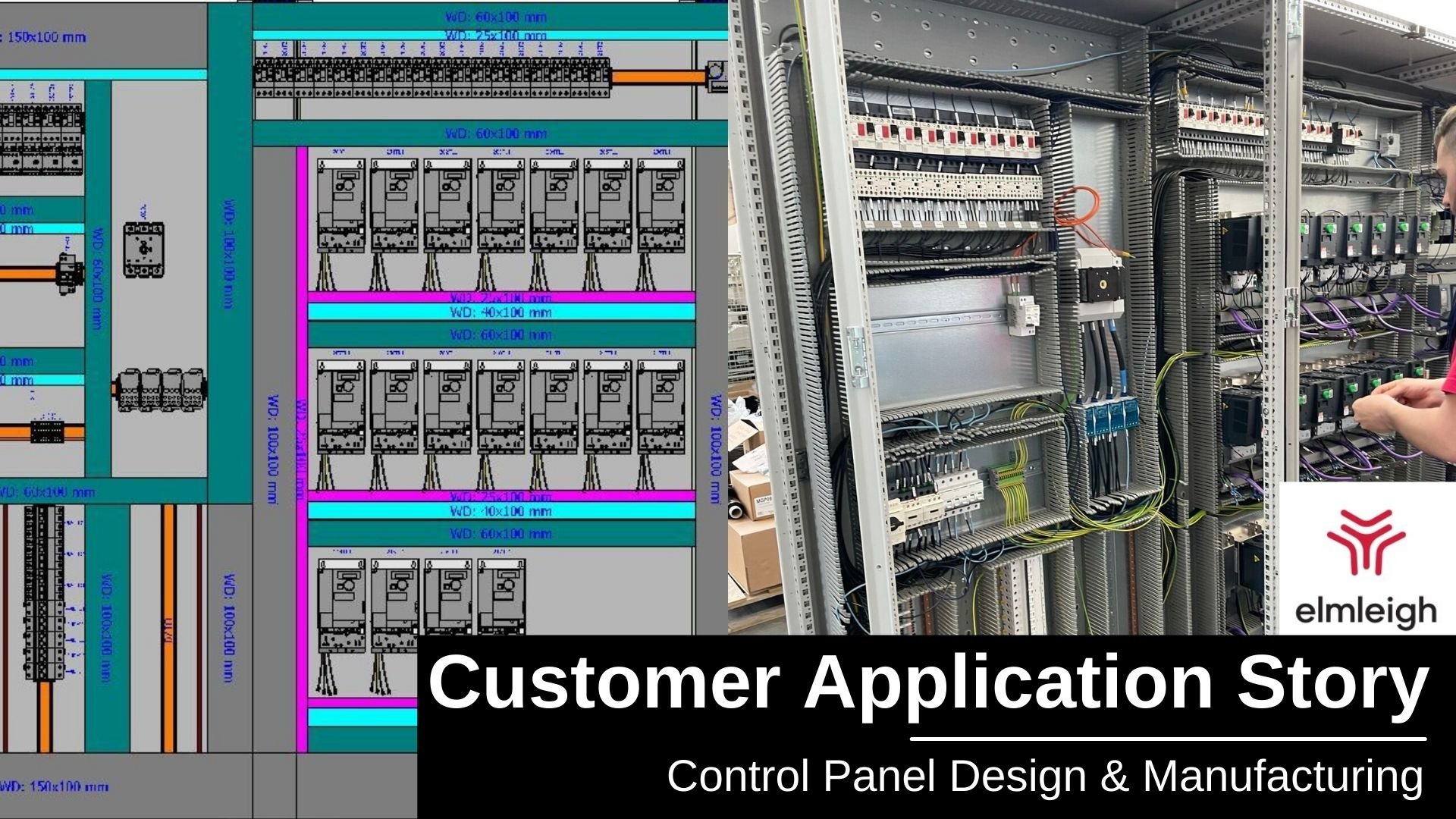

How Eplan Transformed Elmleigh Electrical Systems Limited’s Growth

Having identified Eplan as a tool that supports efficient, high quality schematic and panel design, Elmleigh purchased several Eplan solutions in 2018 and now consider Eplan to be central to the company’s business growth and future development. Chris Southwell, Elmleigh’s General Manager comments “Eplan continues to be at the core of our investment, that I’m sure will continue to push the capabilities and capacity of the design team here at Elmleigh.”

The Project

|

The Challenges

|

The Solutions

|

Why Switch to Eplan Electrical Design Tools?

Prior to using Eplan, the design team used traditional CAD tools for schematics and panel design. The CAD tool required engineers to follow manual, labour-intensive processes for creating schematics and drawings for assembly. 2D panel layout designs could only offer limited detail and were unable to provide an all-round design perspective.

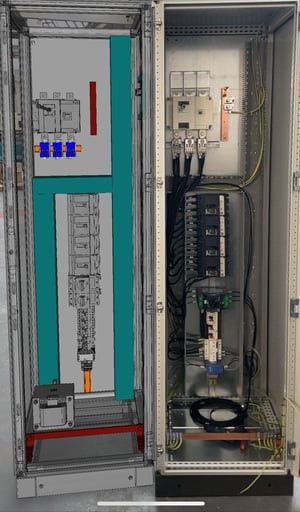

After migrating to Eplan solutions, Elmleigh engineers were able to create electrical schematics in a fraction of the time compared to previous CAD software. With the help of Eplan Pro Panel, they have also been able to create detailed control panel layout designs in a 3D environment which have greatly benefited their assembly activities.

Eplan software provides a stable foundation for automating and industrialising panel building and provides an integrated solution which connects every engineering discipline – from initial system design and project planning to the design of switchgear, cable harnesses and fluid power systems. With Eplan supporting a wide variety of engineering methods – from manual creation to standardised and template-based approaches – project data, once entered into the schematic project, becomes the foundation for automation.

Each project created by Elmleigh is supported by the Eplan Data Portal where there are extensive product catalogues from more than 350 global manufacturers of electrical, mechanical, hydraulic and pneumatic components, offering over 1 million data sets which can be easily dragged and dropped into projects.

Eplan Pro Panel features a built-in collision check which enables engineers to avoid any need for repositioning components before the final build, as well as effortless thermal control design which is coordinated through the RiTherm tool which is integrated into Eplan. Rittal Therm enables engineers to select the correct cooling equipment to deliver optimum thermal control, automatically pulling through from the system all the necessary calculations around sizing and performance.

Once the design work is complete, the system creates a digital twin for effortless, 360 degree, cross-team sharing. Projects can be exported from Eplan in various file formats e.g. NC Data or via direct interface to manufacturing machinery for panel cut outs or wiring for example.

Electrical Design Engineering Made Simple

Eplan tools and cloud-based platforms are now used by all members of the Elmleigh electrical engineering team for designing control panels and creating cable schedules. The latter had previously been created manually by using excel spreadsheets. But now, Eplan automatically generates and exports cable schedule data. The Data Portal has an extensive product catalogue that is accessed on a daily basis.

The overall time savings, according to Design Engineer Alex Anderson, have been “massive” both in terms of design work and for those on the shop floor.

Moreover, Eplan’s tools have delivered the anticipated improvement in terms of the quality of the design output. This ensures that any issues can easily be identified at design stage, rather than further down the line in the workshop which can be costly to put right.

Eplan eView not only allows engineers to upload, store and share projects in the cloud, but also helps to reduce paper usage within the business, and has therefore become Elmleigh’s specified platform for any “red lining” to communicate corrections or adjustments. eView will soon become the preferred way of sharing project work with new customers.

There is even a virtual reality capability within the Eplan platform. The eView AR App places the digital twin virtually within a physical environment. This useful product extension helps Elmleigh’s engineers clarify the panel’s positioning and allows for a more detailed examination of what the finished panel will look like in-situ.

Working practices, particularly during the pandemic, have been supported through Eplan’s eManage. This tool publishes designs to eView and has proved very helpful to Elmleigh’s engineers in supporting remote inter-team and intra-team collaboration.

Other jobs such as labelling terminal blocks, cables etc are now seamlessly managed through the Phoenix Contact Project Complete. The software interfaces with Eplan and creates professional labelling that can be exported across to the workshop team rather than individually typed out.

The company is now considering future investment in Eplan’s Smart Wiring wire routing product offerings to streamline panel wiring.

Panel Building on the Workshop Floor

Elmleigh’s engineers preferred enclosures are Rittal AX, VX and hygienic enclosures due to the components being available in the Eplan Data Portal. The popularity of these enclosures is in part due to their simplicity and ease of use and also because of their large associated range of accessories.

User-Friendly Experience

Alex Anderson, Elmleigh’s design engineer, was already familiar with Eplan when he joined the company a few years ago. He says it was a relief to know that he would continue working with the same tools at Elmleigh because, as he says, “I didn’t want to take a step backwards. CAD tools involve a lot of manual processes, legwork, and working-up trunking literally line by line. There’s no intelligence; it’s just a flat drawing. It means my job is about being an engineer, rather than primarily about drawing.”

Alex also recognises the need for an investment in training to become fluent with Eplan, and advises that it, “does involve quite a steep learning curve – especially for anyone making the switch from traditional CAD systems - but it really pays off in the long-term.”

The team is assisted in its project design work by the Eplan Solution Centre, a support service which has proved consistently highly responsive in answering questions, typically within an hour.

Eplan Supporting Future Business Expansion

Eplan tools are integral to Elmleigh’s operations, that they are part of the company’s planning to speed up business growth in panel building. Put simply, Eplan is expected to be central to the business’s future expansion plans for the foreseeable future.

Ken Christie, Country Director for Eplan UK comments “efficient engineering is our focus, and we’re here to satisfy our customers’ wishes by helping to solve any issues they may have, while ensuring that our energies are on providing software solutions which deliver cost-effective design. Working with Elmleigh, we’ve seen that the right CAE software tool can significantly speed up the design process, but also the positive impacts it can have on both up and down stream processes such as sales and production.”

About Elmleigh Electrical Systems Limited

Elmleigh Electrical Systems Limited are specialists in the integration of electrical and mechanical automation systems. The company offers a complete project management service from conception through design, manufacture, assembly, testing, installation and certification to provide a total system solution.

The panels it builds are used in a range of different sectors including food and beverage, materials handling, and water/wastewater management.

Do you want to learn more about how Eplan could help you achieve your specific goals? Request a software demo to show you which Eplan solutions will deliver the biggest efficiencies for both the engineers and the company as a whole.

Comments