Author

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

Andrew Mutch

Having previously worked as an aircraft technician with HM Forces, Andy is one of our Professional Services Consultants and has been with EPLAN for 10 years. Part of Andy's role is to actively analyse customers processes, develop solution concepts and workflows for customer requirements. Andy is also our resident Harness expert!

Mutch.a@eplan.co.uk

Andrew Mutch auf LinkedIn

The Eplan Platform: Built for 3D Design

In this article, we’ll explain how four Eplan solutions can revolutionise the way cabinet design and production is undertaken.

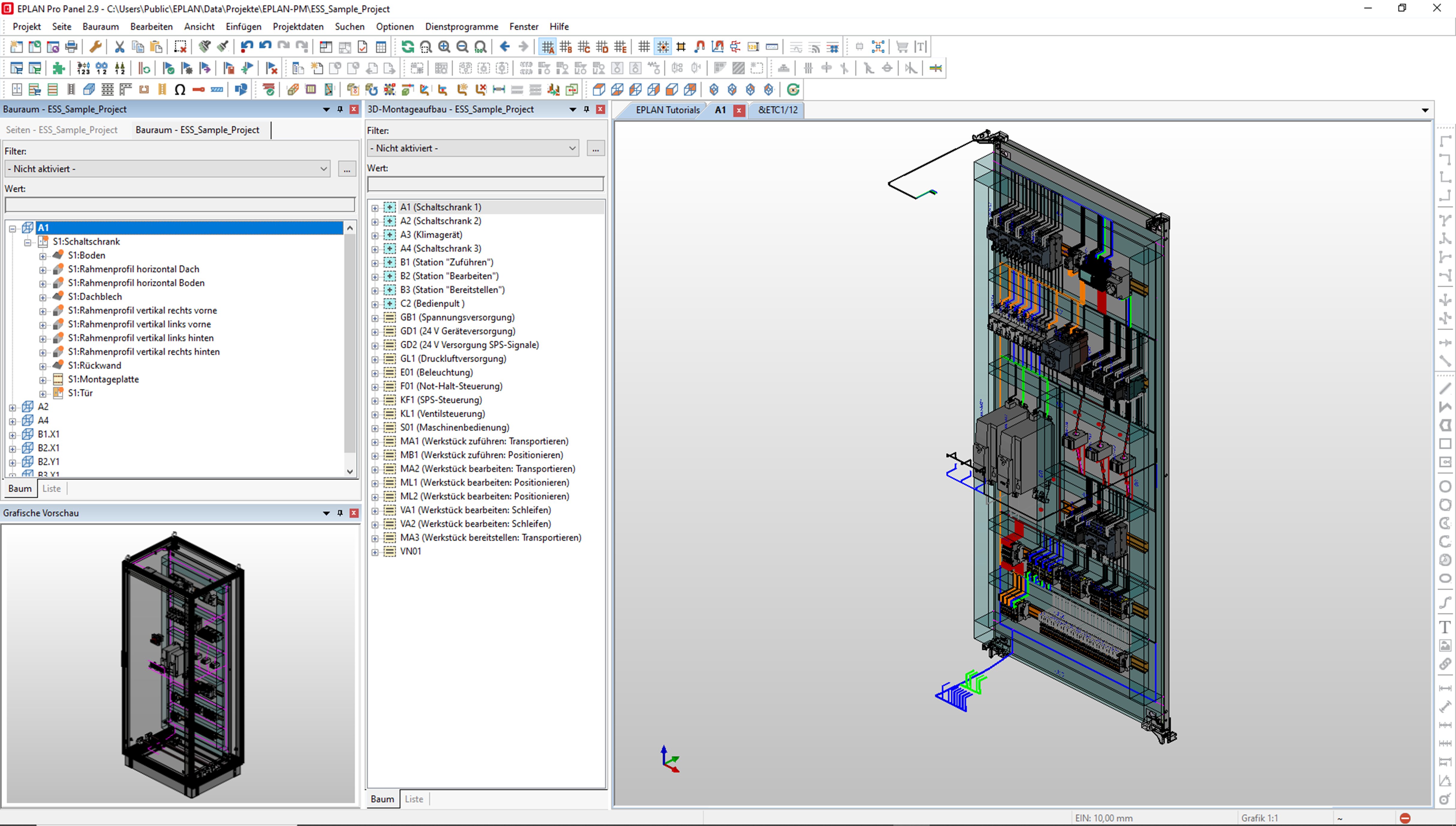

Eplan Pro Panel

Eplan Pro Panel transforms cabinet design and production by offering a comprehensive, integrated solution for the 3D design and construction of control cabinets, switchgear systems, and power distribution systems. This powerful tool streamlines the engineering process, facilitating the automation and manufacturing of panel building. With a toolkit of advanced features, users can efficiently plan mounting layouts in 3D and virtually route electrical and fluid power connections.

Eplan Pro Panel Professional enhances manufacturing processes by providing crucial data for tasks such as component labelling and manual wiring. A single software solution, Eplan Pro Panel supports a range of engineering tasks, simplifying and optimising the entire design and production workflow.

Eplan eView

Cabinet design and production can be complex, so Eplan eView simplifies the process by making project data digitally accessible to all stakeholders, including engineering, manufacturing, assembly, service, and maintenance teams via the free Eplan Cloud. The Eplan eView Free AR add-on enhances the user experience by enabling users to share and project 3D electrical designs into their physical environment using augmented reality, allowing an interactive review of designs and linking 3D device representations to their corresponding 2D electrical schematics.

Eplan eView makes engineering review processes easier by facilitating simple collaboration between staff, customers, and service providers. Common challenges are addressed, such as out-of-date, illegible, or missing control cabinet and machine documentation. With eView, users have easy, cloud-based access to the latest schematics via a web browser, regardless of their location. Easy accessibility ensures that up-to-date 3D visualisations of control cabinets are always available, enhancing maintenance, servicing, and overall project efficiency.

Eplan Smart Mounting

Eplan Smart Mounting streamlines production by offering a precise and efficient method for placing components within control cabinets. Utilising the digital twin from Eplan Pro Panel, it provides checklists, clear working instructions, and corresponding 3D visualisations. Assembly technicians are guided through each installation step, from DIN rails and cable ducts to electrotechnical components, offering tailored support during each process and visually indicating the exact placement with dimensions for components within the 3D model. Technicians benefit from immediate access to detailed component data and visual aids, enhancing production efficiency.

Furthermore, Eplan Smart Mounting employs a traffic-light system to track the installation status of each component, indicating completed tasks in green and pending ones in red. This feature, coupled with a comments function for communication with the engineering department, ensures a seamless and integrated production process.

Eplan Smart Wiring

Eplan Smart Wiring simplifies the wiring process during the production of electrical cabinets. By providing a clear visualisation of each step, it ensures that wiring is efficient and error-free.

Wiring technicians receive detailed, intuitive step-by-step instructions, allowing them to choose individual wiring of displayed connections or a predetermined sequence. The progress of wiring tasks is monitored using a simple red-yellow-green traffic light system, helping engineers to keep track of their progress.

A key advantage of Eplan Smart Wiring is its ability to facilitate wiring without direct reference to schematics which, when needed, are conveniently stored in the assistant for quick access. The software also offers an easy-to-read visual representation of mounting layouts, devices, connections, connection types, and wire routing, streamlining the wiring process and reducing the likelihood of errors. This leads to a more efficient, accurate, and streamlined production process during panel building.

Unleash The Power Of Eplan

Eplan develops leading-edge digital twin software for both control cabinet design an wire harnesses to help visionary engineering businesses improve their engineering processes and take their companies to the next level, leveraging the benefits of digitalisation, automation, and Industry 4.0. These solutions offer automated wire routing and drilling information, as well as, having an interface with Rittal RiTherm which determines the required air-conditioning for heat dissipation. To find out more about our software solutions and how they can benefit your business, please call 01709 704100 today.

Comments