Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

From Sales to Configuration

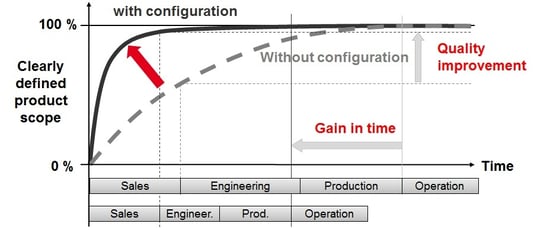

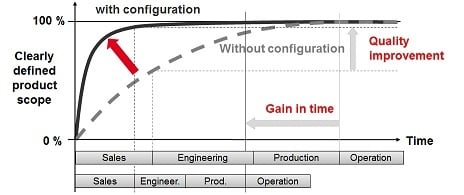

The sales process lays the foundation for a streamlined and cost-efficient engineering and production process. During the sales consultation, the sales team often make unrealistic promises to the customer based on the customers' requirements. They think that nothing is impossible for the engineering department, which often leaves the engineering department facing many new challenges. There is a simple solution to this problem - give the sales team the tools to configure the products themselves with their customer.

Even though the sales team are not engineers, it is important that they have engineering knowledge so that they know the product specifications and can make deliverable promises to the customer. Even the smallest change can have far-reaching consequences for the subsequent functionalities of machines and installations. Unforeseen problems often only come to light later in the process stage, which is when the costs increase exponentially. It is important to eliminate these risks whilst remaining flexible for the customer.

Project Business: What will change?

Project Business: What will change?

Multidisciplinary Standardisation

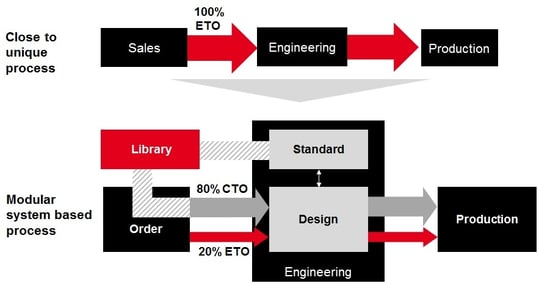

Specific customer requirements usually lead to customisation, which is more work for engineers. To make both the sales and engineering process more efficient, customisation should be as 'standard' as possible. This requires a different approach to engineering, in which the complete range of possible products is distributed to ALL DISCIPLINES and STANDARDISED in smaller functional components. These components are reusable and can be combined with one another to make new products. When these functional components are created according to the relevant specifications, you can use them to generate the most common customer requirements.

Configure New Products

By dividing these functional components into basic modules (building blocks), it is now possible to CONFIGURE 'customisation' solutions rather than engineering them. The different configuration variants and options that are already stored in the standard can now be allocated.

Increase efficiency with configuration

Increase efficiency with configuration

In the sales stage, the solutions can be configured with the customer using a system in which a lot of engineering know how is stored. Such an intelligent configuration system only suggests the product options which correspond with the previously chosen parts. There are so many advantages to this, including no errors or annoying surprises at a later stage in the process.

A Configure-to-Order (CTO) process replaces the familiar Engineering-to-Order (ETO) process approach in both series construction and individually designed solutions.

Reducing costs in the engineering and production process starts with sales. Configuring solutions with the customer lowers the cost and chance of making mistakes. Multi-disciplinary standardisation is necessary to allow sales to do this.

What does this mean for the engineering process? More will be said about this in our next blog. Stay tuned!

Comments