Author

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

How can you engineer quicker?

Traditionally, electrical engineers design schematics in a way that is easy for panel builders to manufacture. Functional design enables engineers to add additional modules easily and quickly without the need for major modifications. Also, it makes it easier for maintenance engineers to trouble shoot because all the necessary circuitry for one function is grouped together on one page. How can your engineering team use functional design?

Reusing old projects is not a new concept. Your engineers probably copy old projects and modify them by adding customer specifications to them. This means that it is likely that an error will occur or something will be forgotten. As you would expect, errors do come to light, but the later they are found, the bigger the cost to fix them. With functional design, your team can engineer faster by reusing projects. It also helps detect and prevent errors earlier in the engineering process.

What is functional design?

Functional design is splitting a system’s design into groups by function. Within each function module, similar functions are divided into sub-modules and so on. The central library is built up with sub-modules for the most frequently used customer requirements. Your engineers can create projects from these standard modules (e.g. via Configure-to-Order) and, if necessary, supplement part of the project with customer-specific engineering (Engineer-to-Order).

How does your team create a useful functional design?

The first and most crucial step in this process is agreeing the structure of products and projects, and the definitions. Functional design is the method used to shape this structure. It is best illustrated with a real life example.

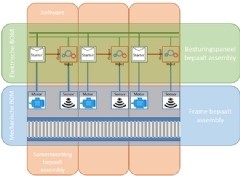

Imagine we are making a conveyor belt system. This setup has three conveyor belts that are connected to one another. Each conveyor belt has a sensor, motor, electrical control, and software that coordinates everything. This setup has a mechanical bill of materials (BOM) for the machine and an electrical BOM for the control cabinet. In the illustration below, you can see our setup graphically.

Assembly

Assembly

Which element determines the division or assembly? Different engineers think differently about this:

- Mechanical - Frame determines the assembly: 1 frame, 3 motors, 3 conveyors, 3 sensors

- Electrical - Panel determines the assembly: 1 panel, 3 motor starters, 3 sensors, 6 cables

- Software - Function determines the assembly: (3x) the collaboration between motor and sensor

In functional design, we look for a general division, which is not discipline-oriented but is function-oriented. The software is the binding factor between mechanical and electrical, because the software determines how the machine works via the control system. This functional method forms the basis for dividing the setup into process modules.

Options

The next step is splitting these functional process modules into options. Which options do we need? There are also different opinions about this:

- Mechanical

- Frame width: 500/750/1000 mm

- Conveyor: rubber tyre/rollers

- Product material: metal, cardboard, plastic - Electrical

- Motor power: 0.75/1.5/3.0 kW

- Motor control: direct online/Star-Delta/Softstart

- Sensor type: digital (DI), analogue (AI) - Software

- Type of motor control: direct online/Star-Delta/Softstart

- Acceleration, gear, delay, start, stop

Configurable process modules

The particular option you choose has consequences on the available options in other disciplines. A configurator helps you to make the right decision:

Thanks to configuration, it is possible to select options from several disciplines from the same module.

Reuse knowledge

Some may think that function-oriented thinking does not allow room for creativity, but it is probably the best way to include complete information for everyone.

Functional design is a crucial link in accelerating and improving the engineering process. The knowledge of engineers is stored in the library of functional modules, which are ready to be reused in new projects. These basic designs have been thoroughly tested and have proved themselves in practice. Your team saves time and errors are prevented as a result.

Comments