Author

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

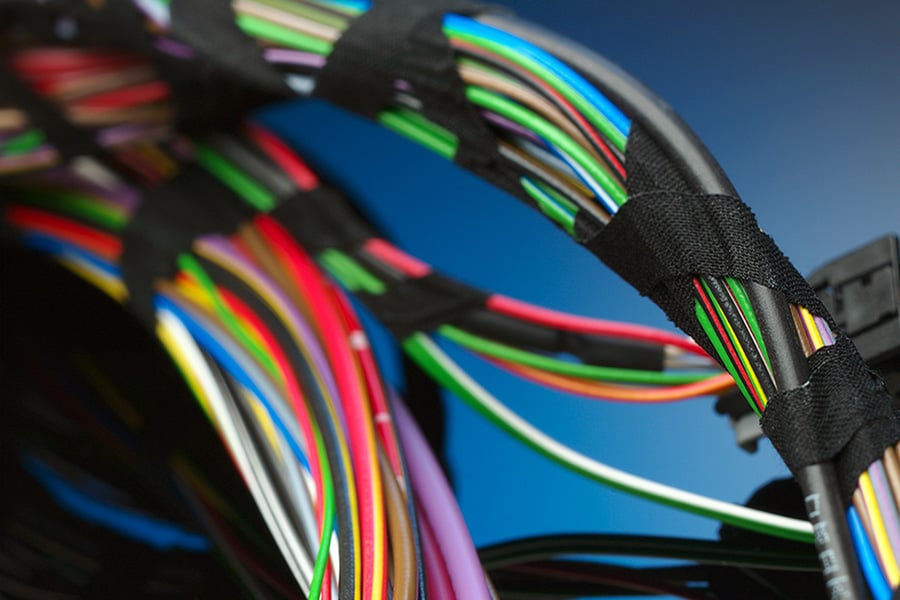

Improve Machine Cabling Efficiency: Advantages of EPLAN Harness proD

In just a few words, can you explain what EPLAN Harness ProD software can do?

EPLAN Harness proD enables engineers to carry out digital electrical design within a 3D system. This makes it possible to independently determine the cable lengths on the 3D model of the mechanics. The software supplements the information content of the circuit diagram. In addition, EPLAN also provides an HTML export that installers can use to see how the engineers planned the installation of the cables. This ensures smooth implementation and installation.

What are the current trends in machine cabling?

The range of pre-assembled cables is expanding as manufacturers strive to meet the growing demand. One key player in this market, EPLAN Harness proD, is revolutionising the use of pre-terminated cables, providing invaluable guidance for installers and significantly improving efficiency. With Harness proD, the once daunting challenges of installing cables are a thing of the past. Designers no longer have to worry about too small openings, limited installation space, or cables that are either too long or too short. EPLAN Harness proD effortlessly solves these issues, ensuring a smooth and hassle-free installation process.

The progressive digitisation and networking of machines require increased cabling to integrate sensors, actuators and other components into the production environment. In addition to this, the increasing demand for compact machines and devices means that cables must be carefully installed to save weight and space.

"EPLAN Harness proD digitises machine cabling and enables engineers to design and precisely document complex cable harnesses earlier in the process."

What advantages does EPLAN Harness proD offer for machine cabling?

We have developed a 3D system for electrical engineers that is easy to use and designed to quickly place and route components such as connectors and cables. In addition, we have a wide range of interfaces; you can import all common MCAD formats and access the EPLAN circuit diagram project directly, and if the project is available, even the control cabinet structure including the connection logic of the components in the cabinet is adopted - this is where most of the cables run into the machine. EPLAN Harness proD improves the process of machine cabling and enables engineers to efficiently design and precisely document complex cable harnesses.

How does EPLAN Harness proD help optimise the complexity of machine cabling and achieve high-quality results?

This solution fundamentally changes the process of machine cabling! During development, Harness proD helps to ensure that all cabling information can be obtained from the digital model. A very important factor is the information about the length of the cable. If cable lengths are known early on, pre-assembled cables can be used instead of bulk goods, which also must be assembled manually. This saves time and effort, while improving cabling quality and reliability. Furthermore, the cable installation route is fixed after the development, and the installers can use the viewer to visualise specifications. Today, a lot of responsibility lies with the engineers and designers, since many machines are manufactured differently, so a technician must first read whether service is required. Harness proD is a great help with this.

“We are changing the process of cabling. We are rethinking it and using digital tools to effectively solve the challenges such as lack of space and inappropriate cable lengths in the working environment.”

Which specific functions or features of EPLAN Harness proD have proven particularly useful for machine cabling?

It cannot be broken down to the functional basis: we are changing the entire process of machine cabling. The use of digital tools to effectively solve challenges such as a lack of space and unequal cable lengths in the work environment. We have reached a major milestone with the provision of a viewer in HTML format – this is my personal highlight from the last software versions. This is the only way to implement planning in production without having to compile elaborate instructions for the installers.

How does EPLAN Harness proD support its users in optimising the use of space in the cabling of their machines and saving costs?

With the help of EPLAN Harness proD, early and enhanced planning is fully supported. While it may require some additional effort during the design phase, our experience has shown that this investment quickly pays off. By knowing in advance which pre-assembled cables need to be ordered and ensuring they fit seamlessly into the planned paths, the entire cabling process becomes more transparent. This enables faster and more consistent cable installation, resulting in a significant increase in employee productivity and the overall quality of the cabling. In essence, a well-coordinated design at the end of development eliminates any unexpected surprises during production.

Comments