Author

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

John Boynton

John has worked for EPLAN for 24 years and is our Technical Business Manager. A member of The Institute of Engineering & Technology, and The Engineering Council for over 20 years, John has a wealth of experience and skills ranging from analysing customers' processes in order to identify areas in which could be made more efficient, to project management, consultancy, method counselling and project commissioning.

boynton.j@eplan.co.uk

John Boynton auf LinkedIn

Interview: Martin Richter from CadCabel

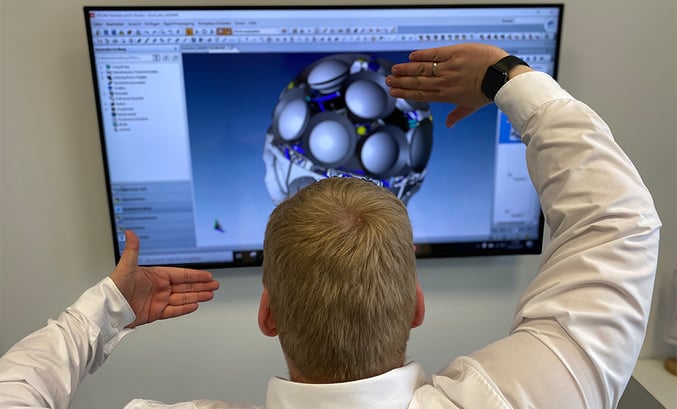

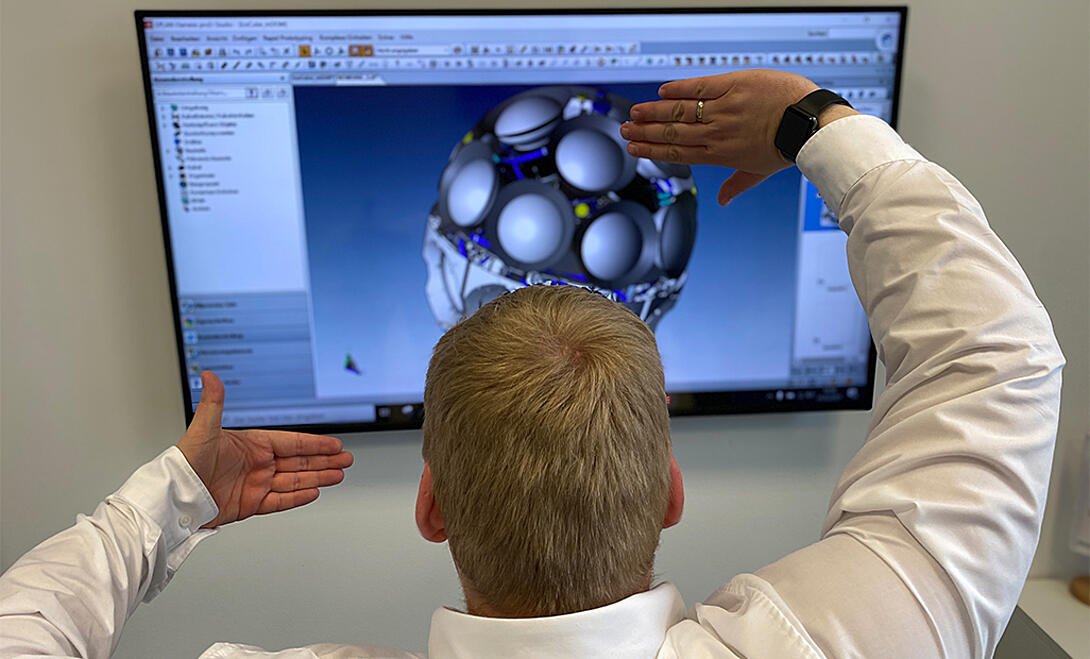

In your current project with DESY, you are wiring individual modules for the largest particle detector in the world, the IceCube telescope. What is the goal?

The digital optical modules or DOMs for short, which we wire, are embedded meters deep into the eternal ice of the Antarctic. They are so sensitive that they can detect the smallest particles of galactic or extragalactic objects - so-called neutrinos. The south pole with ice up to 2.5 km deep offers ideal conditions for the detection of these particles.

What is the biggest challenge in this?

To many people's surprise, snow and ice are not the biggest challenges, but it is in fact the limited space available. Think of it this way: the DOMs that we wire are no bigger than a soccer ball. Here we have to accommodate between 50 and 60 cables that deliver high-precision data. These cables are not even 2 cm wide; the coaxial cable is really tiny at 1.6 mm wide. To save space, we use ribbon cables that can be kinked. Their handling requires a lot of experience and skill and they are difficult to route or lay in 3D. However, all of this can be done with EPLAN Harness proD. We have just recently completed the prototype and are looking forward to getting the DOMs into mass production. In the recent webcast I tell you more details about the DESY project, which is really a highlight for every cable and wire harness designer.

To many people's surprise, snow and ice are not the biggest challenges, but it is in fact the limited space available. Think of it this way: the DOMs that we wire are no bigger than a soccer ball. Here we have to accommodate between 50 and 60 cables that deliver high-precision data. These cables are not even 2 cm wide; the coaxial cable is really tiny at 1.6 mm wide. To save space, we use ribbon cables that can be kinked. Their handling requires a lot of experience and skill and they are difficult to route or lay in 3D. However, all of this can be done with EPLAN Harness proD. We have just recently completed the prototype and are looking forward to getting the DOMs into mass production. In the recent webcast I tell you more details about the DESY project, which is really a highlight for every cable and wire harness designer.

Apart from the DESY project, what is your experience in the field of cabling?

I more or less slipped into it. Years ago - at that time I was still project manager for switch cabinet construction - a company representative approached me with the request that I should do something for him in 3D. So, I started routing with EPLAN Harness proD as the quality software also included a 3D function.

Martin Richter focuses on 'digital optical modules'.

Martin Richter focuses on 'digital optical modules'.

I particularly remember the thickest cable I have ever laid. At 800 square millimeters, it's about as thick as my thigh. I was also able to map this in EPLAN Harness proD. In addition to space, the many existing requirements, such as EMC requirements, are an important issue. They are stored directly in the software, which makes correct wiring much easier. I can only say: nowadays we are far from the hand-drawn wiring plans of the 1990s. Cable and wire harness construction is a highly professional business in which we plan down to the millimeter.

Intrigued to know more about the project? Martin Richter kindly spoke to us in a live webcast 'Best Practice: Wiring the largest particle detector in the world - A practical example from CadCabel I DESY I EPLAN'. Luckily for you, we recorded it so you don't miss out!

Comments