Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Employer branding with EPLAN: How modern engineering can attract new employees

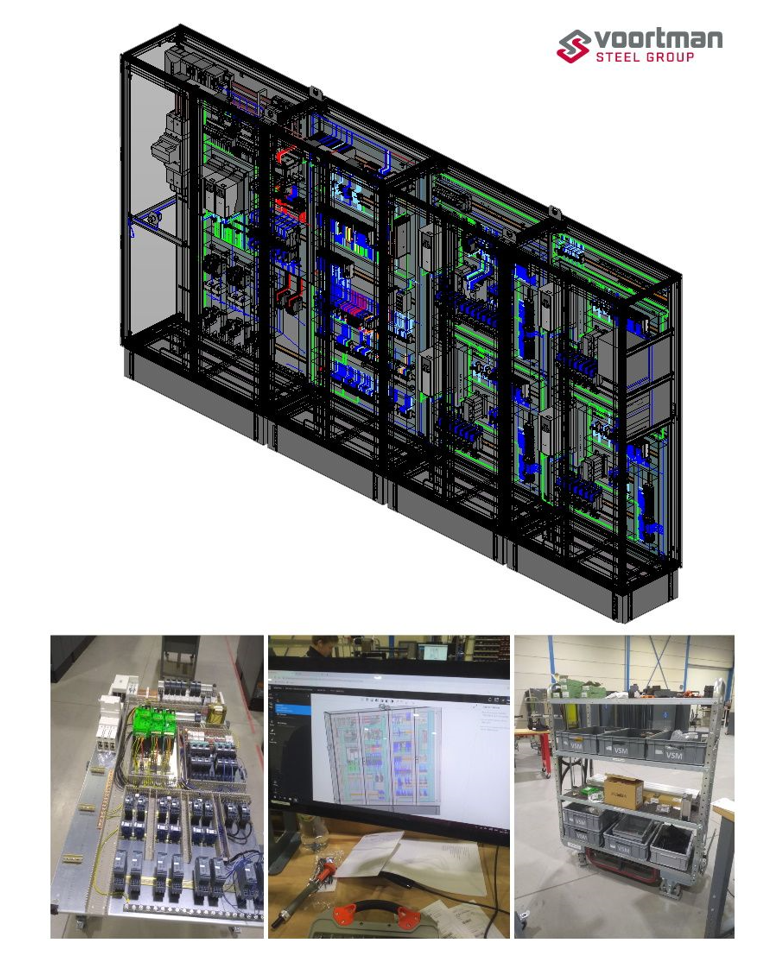

Voortman Steel Machinery is a manufacturer of configured to order steel processing machines. In the search for the most effective working method, many activities and work steps were brought (back) in-house. For example, the control cabinet construction, which has been carried out in cooperation with the partners Rittal and Eplan since 2020. Voortman products mostly consist of standard units that can be assembled individually. This way of working makes it possible to standardise and automate a large part of the engineering using Eplan Pro Panel and Eplan Engineering Configuration (EEC).

Post featuring Eplan 3D graphics goes viral on LinkedIn

"Last year we switched all of our standard units to Eplan Pro Panel," says Marc Pluimers. "This is now paying off in production. Another side effect is that you can use the program to create beautiful colored 3D images of the control cabinets.' Marc Pluimers continues: 'I once posted a 3D image of a schematic on LinkedIn just to show how cool it was. The enthusiasm about this representation was great in traditional control cabinet construction. The post went viral. That's when I thought, 'If I'm getting such a wide reach with these images, why not add a link to our careers page in the post?' So I just did that."

Voortman Steel Machinery: leading in products and processes

Marc Pluimers wants to show that Voortman is a leader as a company and constantly strives to improve both its products and its processes. He explains: “We are looking for people who want to work for us in this sense. A mix of technician and someone who understands our processes and wants to improve them. I hope that I can address such people with my posts by showing how innovative we work.” Has that already paid off? “The applicants are not yet lining up in front of the door, but we have already found a new colleague. He said Voortman's progressive approach was important to him in deciding to work for us.”

Is Eplan software crucial for applicants when looking for a job?

The demand for technical staff is high and specialists are difficult to find. The demand will continue to increase in the coming years as many people are needed not only in the automation industry but also in the energy sector. In short: Employers need to stand out in the job market. “I was curious whether software like Eplan would be crucial when choosing an employer in the automation industry. New colleagues felt that this was not crucial for them but was definitely an advantage for potential employers. The prerequisite is that the software is used correctly. That saves a lot of frustration and creates space for the actual work," says Pluimers. His conclusion: "So we're on the right track here. Voortman makes extensive use of Eplan. We've put a lot of time and effort into optimising our databases. Consequently, we use the software at a very high level and use, as well as new solutions from Eplan. Now and then there are small difficulties. Nevertheless, standardisation brings us a lot, for example, we save time, money and fewer mistakes. And that's more relevant than the occasional bug."

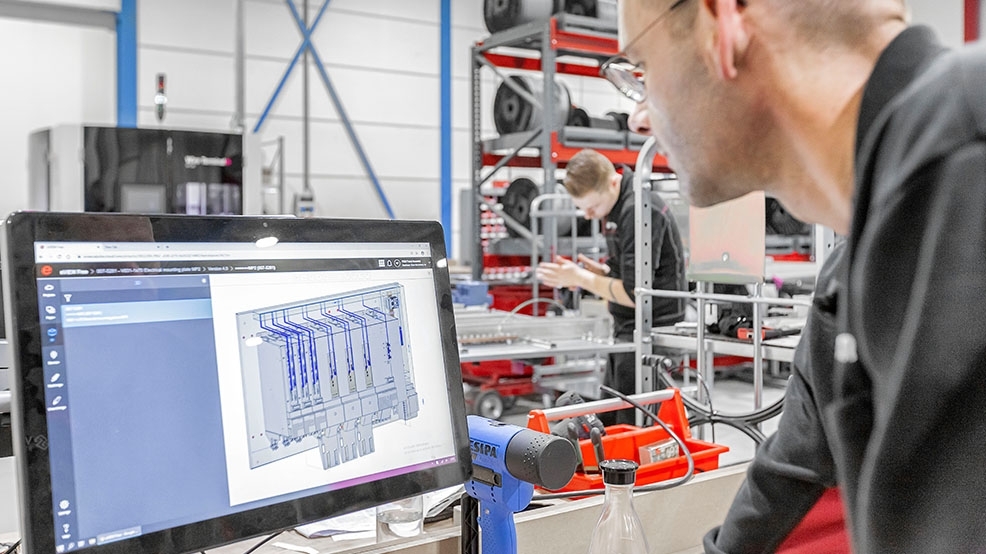

Changed job description of the engineer at Voortmann

The work of an engineer at Voortman has changed due to the automation of the work fields. “On the R&D side of our company, things have become more complicated in terms of configuration. Eplan Pro Panel ensures that we can have complex work such as the construction of control cabinets carried out by less technically qualified people," says Pluimers. “By providing more information in the design, the work in control cabinet construction becomes clearer and therefore easier. The challenge here is quantity rather than complexity. The big advantage, however, is that we can leave repetitive tasks to less qualified personnel, which means that the technicians have more time for the complex tasks. That is of course a big win.”

Conclusion: In order to master the challenges of the shortage of skilled workers in machine and control cabinet construction, new ideas are needed. Voortman Steel Machinery attracts potential employees with automated processes and modern software for electrical engineering.

Here are what other customers have to say...

How EPLAN delivered major efficiency gains for leading retailer

How EPLAN became central to Elmleigh Electrical Systems Limited’s future growth plans

EPLAN helps system integrator InControl grow its professional services

Comments