Author

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

Ken Christie

Ken Christie is the Country Director at EPLAN UK. He has been working at EPLAN for 9 years with his expertise in the electrical design industry.

Ken Christie auf LinkedIn

The Basics of Automated Test Runs in Eplan

Circuit diagrams are complex, so it isn’t surprising that errors can occur during the project planning stage. The earlier you discover these inconsistencies, the smoother the installation process will be. The accuracy of circuit diagrams has a positive effect on the documentation and influences downstream evaluations. These evaluations include terminal and cable connection diagrams, equipment and article parts lists, structure code overviews, and flow charts.

What is a Test Run in Eplan?

A test run is an automated check run: if you initiate it in Eplan, the software runs and analyses whether your circuit diagrams are correct. If Eplan detects errors in your circuit diagram, you will receive a message alerting you of this. Some suppliers like to advertise in their references that the test run of a completed project was “message-free”.

However, some system operators may be put off by the message alerts. By dealing with the causes and sharing the test results with suppliers, you could challenge and overcome your “audit anxiety”.

We will show you the basics of inspection runs to demonstrate how simple it is to check circuit diagrams in just three steps.

Step 1: Use Predefined Test Runs

To avoid getting lost in the beginning, we advise that you don’t start from scratch.

There are two possible starting points:

- You have a supplier who hands you their projects in excellent quality. In this case, use your supplier's last project as a basis and refine the error messages you want to see.

- Go to www.eplan.co.uk and scroll down to Eplan Services. Here you will find the Eplan Engineering Standard, or EES for short. This offers you various downloads, including the “Basic project for IEC”. The basic project offers you universal templates with predefined evaluations and settings with which you can set up projects according to the IEC standard.

As soon as you have developed the test runs according to your requirements, your basic project is ready for dispatch. You should share this with your suppliers and specify that this project is for commissioned projects. For example, specify this in your supplier guidelines or in the associated project data sheets to ensure that all of your suppliers build on the same foundations.

Furthermore, you can easily compare delivered Eplan projects with your master project. With the touch of a button, you can find out whether the delivered settings match the specified configurations. You can also ensure that the project structure fits and that all your projects are set up identically, regardless of whether you are collaborating with one or several suppliers.

Step 2: Start Test Run

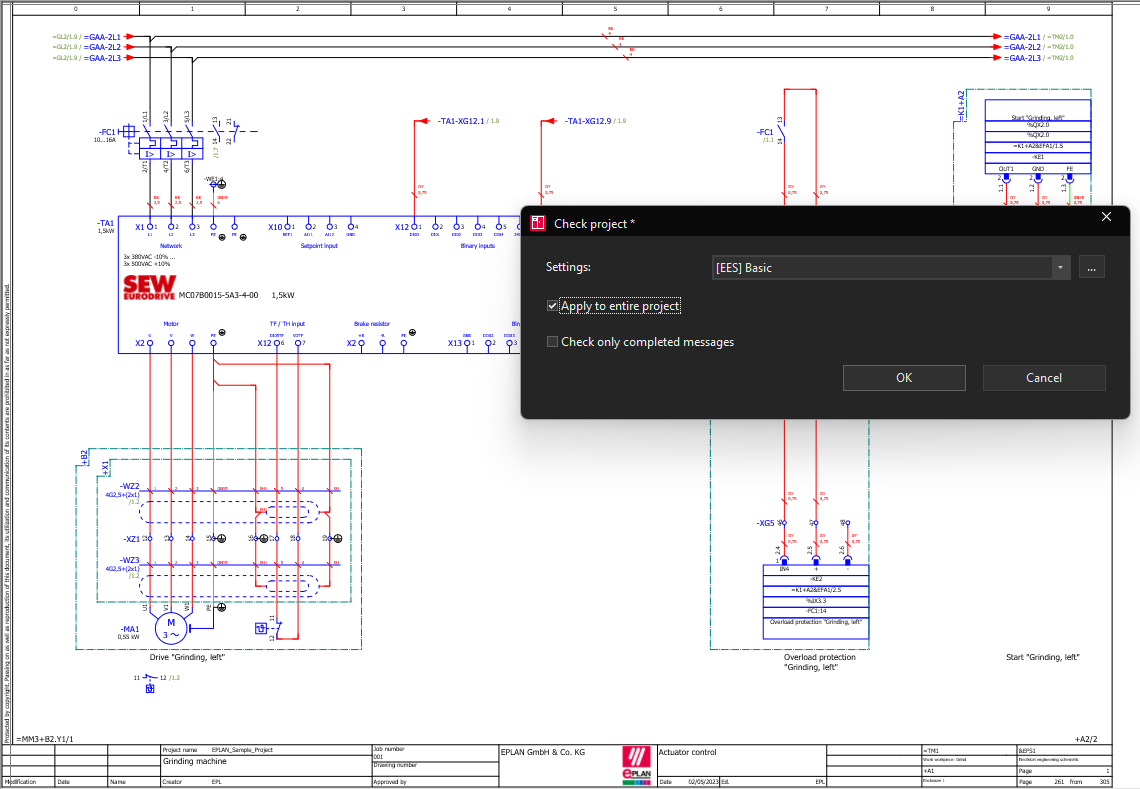

You start a test run by clicking on “Execute test run” in the context menu of the messages. You can find the command in the Eplan menu under “Tools --> Check”. Keyboard shortcut users can alternatively use [Ctrl] + [Shift] + [P].

You can then choose from various schemes:

- You can use the [EES] Basic test run to check the basics. For example, Eplan checks whether all equipment is functionally correctly integrated in the circuit diagram and evaluates the syntax of the equipment used.

- In addition to the basics, the [EES] Advanced test run checks further details on cables, terminals, connectors, and connections.

- The [EES] Expert test run builds on the other two and includes additional message texts, for example on cable lengths or installation routes. This is particularly interesting if you want to use test runs for your digital twin in 3D.

- [EES] Routing is also available for routing checks with Eplan Pro Panel and Eplan Smart Wiring.

Eplan always checks a little more from top to bottom. You decide which test run you start with based on your requirements for the Eplan project. Of course, you can also create and use your own test run schemes. For example, you can name them after the respective company names of your suppliers or customers.

If you are unsure, we recommend that you discuss this with your suppliers or contact the Eplan Consulting team.

Step 3: Understanding Messages and Solving Problems

If the test run finds an error, Eplan displays the detected problem in message management. Each message is assigned to a category and marked with an appropriate symbol. While “Notes” are informative, “Warnings” show a possible problem, and “Errors” call for action. You decide which message you want to categorise and how.

In addition to the category, the message management also displays a six-digit message number. The first three digits indicate the class to which the message belongs. For example, the sequence of digits “001” indicates that the message concerns a terminal, while the sequence of digits “501” indicates a problem with the article master data.

The last three digits of the message number are used to uniquely identify a message within a class. This simplifies communication with your supplier when you are discussing errors or quality gaps in the circuit diagram.

To help you precisely identify a problem, message management also provides you with a brief message description in the overview. This feature is very practical; If you do not understand the message description straight away, you can select the message and press the F1 key. This opens a help page which suggests possible solutions to the problem. If you have additional questions about the message, you can use the search function directly in the help system to do further research and search for the information you need.

Do you follow the motto 'Problems are there to be solved'? Click on a message and select “Go to (graphic)” in the menu. Eplan then jumps directly to the corresponding location in the circuit diagram. If you prefer shortcuts, [CTRL] + [J] is the one for you.

How Test Runs Provide Value

There are three main ways how test runs can be a valuable addition to your workflow.

1. Optimal Use of Article Data

The switch cabinet needs a base and the push-button needs contacts. Define the dependencies that exist between certain articles in the article database. Once the relationships have been dictated, they can be checked automatically via a test run. If individual components are missing required accessory items, Eplan issues an error message.

Terminals and cables are materials that may need to be replaced, so it would be helpful to keep these items in stock in the spare parts warehouse. To do this, you need to know which items have been installed alongside their article numbers. Configure your test run so that it outputs components with missing article numbers as errors, since this will make it easier to operate your system later.

2. Integrate Equipment Correctly

Are all cables connected to terminals or are there still open connections? Does a cable target several destinations or are wires used that the cable does not even have?

Even the basic test run checks whether the equipment used uses more functions than the associated article provides. Eplan also issues an error if equipment is missing its main function. For example, if a contactor has contacts but the coil is not wired.

3. Use Markings Correctly

“Copy and paste” is a widespread method in engineering. It can easily happen that components are labeled identically. Clear designations are needed so that your technicians know whether to wire a wire with the terminal strip at the bottom left or top right.

To avoid this, you can uncover duplicate designations with a test run. Use the key combination [CTRL] + [N] to quickly resolve the duplicate equipment labeling as this gives the equipment the next available designation. Alternatively, you can also use one of the navigators to number them correctly.

Final Thoughts

Would you like to deepen your knowledge of automated test runs? Visit our free five-part eLearning course on “Message management” to expand your Eplan knowledge in just under 40 minutes. Our interactive learning videos also offer you exercises and files to try out and familiarise yourself with.

We hope we have demonstrated why test runs should be embraced rather than avoided. With Eplan, you can use test runs as a tool to eliminate errors and streamline your business processes.

Comments