Author

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

Simon Knibbs

Simon has been working at EPLAN UK for 3 years as an EPLAN Applications Engineer. He started his career in building, services, and moved on to designing and programming early robotics. He then became involved in mechatronic design and PCB layout. Since joining the CAD industry he has always been at the forefront assisting customers. He is a great advocate of value for money and hates to see customers’ investments underutilised through lack of knowledge, configuration skills or investment. He is a firm believer that a consultant’s role is to aid the customer in doing things better, easier and faster. So automation, standardisation and integration into other workflows are his interests.

Knibbs.S@eplan.co.uk

Simon Knibbs auf LinkedIn

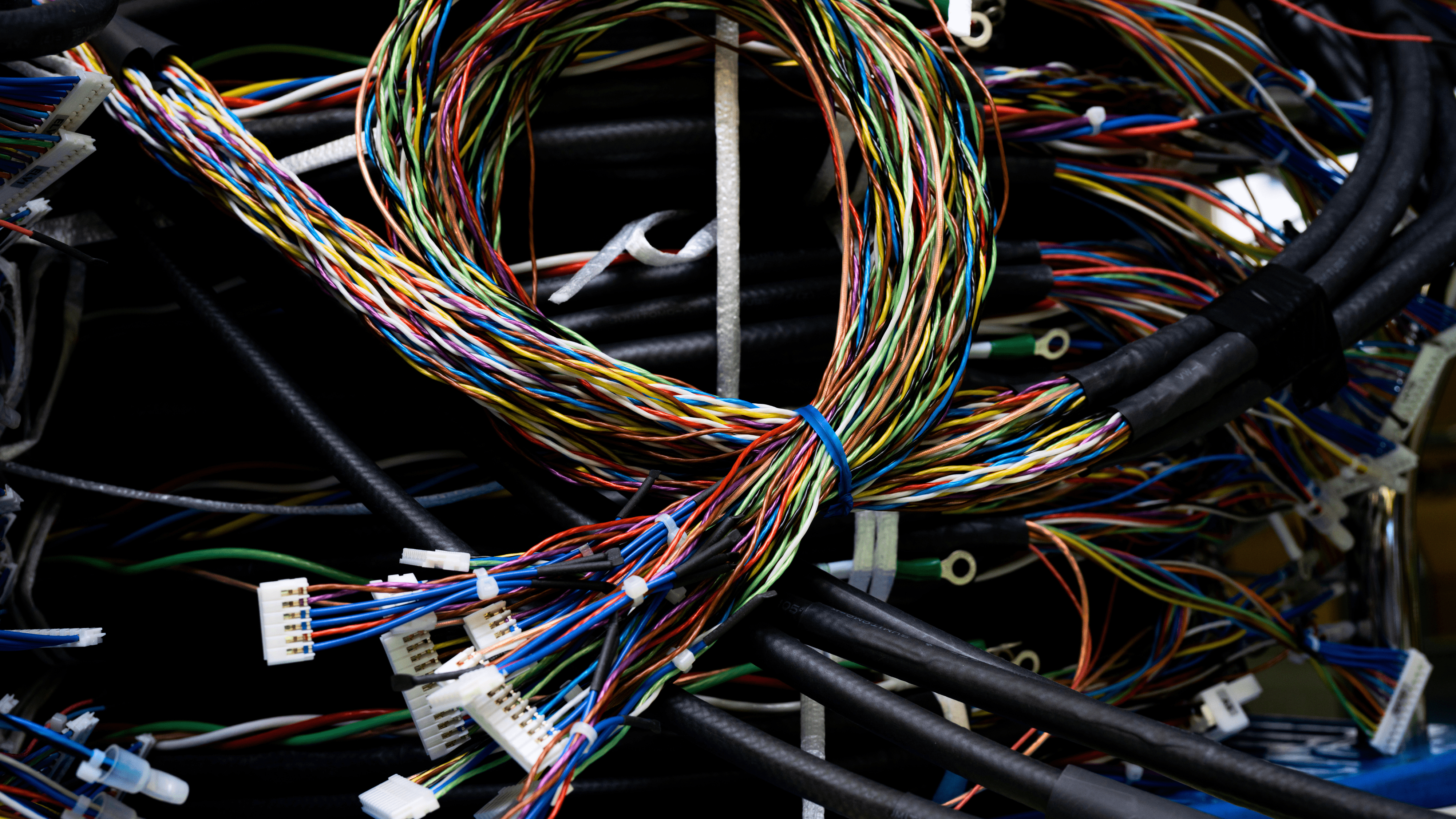

Five Reasons Why Electrical Wiring Harness Design Software is Worth It

As the digital market expands, so does the need for cabling. That's why the market for wiring harnesses is predicted to expand with a compound annual growth rate of 3.95% until at least 2032. With this knowledge, electrical wiring harness design software becomes increasingly vital to optimise routing, maintain system performance, and reduce costs.

Let's explore the 5 reasons why electrical wiring harness design software is worth the investment.

1. Increased Efficiency

A wire harness can simplify electrical installations when implemented properly. Without an adequate design, it's impossible to get the most efficient results. Electrical harness software plays a crucial role in streamlining both the design and manufacturing processes, ultimately leading to faster installation times and improved overall efficiency.

One of the key aspects that enhance efficiency is the use of a digital twin. This virtual representation of the physical harness eliminates the need for time-consuming and costly physical-mechanical prototypes. Additionally, the digital twin offers greater flexibility when revisions are required, allowing engineers to make changes quickly and easily without the need to continuously rebuild physical models to reflect the adjustments.

2. Design Check Rules

Design check rules are an essential component of electrical harness software since this enables engineers to validate their models before transitioning into production. These rules serve as a comprehensive set of guidelines that ensure the design meets all of the necessary specifications and industry standards

Wire harness software encourages adherence to these rules by offering real-time feedback and detailed information on critical aspects. This can include correct terminal sizing, wire protection sizes, cavity seals, and any other required accessories.

This proactive approach helps to identify and rectify any potential issues that may arise early in the design process, therefore preventing the likelihood of costly errors during manufacturing and installation.

3. Routing

Using a 3D digital twin, wire harness routes can be determined with full accuracy during the software phase of system design, well before finalised prototypes or moving into production. This advanced routing capability allows engineers to visualise and optimise the path of each wire within the harness, taking into account factors such as space constraints and any potential interference with other cabling components.

The software typically includes an established catalogue of parts, which provides accurate reporting data for Bill of Materials (BOM), connection details, and manufacturing documents. This comprehensive approach to routing ensures that the final harness design is not only efficient but also fully optimised for each specific application.

4. Improved Quality

The development of wire harnesses when using specialised software markedly simplifies the assembly process and mitigates the risk of costly errors.By creating a well-documented design, improvements range across product reliability and efficiency. Clutter reduction allows for better maintenance and provides greater certainty with routing paths.

Furthermore, the risk of disconnections and short circuits is considerably reduced, as wire harnesses help to protect against vibrations and abrasions that can occur in various operating environments.

Fire hazards can also be mitigated through the use of flame-retardant sleeves which can be easily incorporated into the software. This approach both ensures performance requirements but also improves the safety and longevity of the electronics.

5. Cost Reduction

By simplifying assembly, wire harness development enabled by specialist software, like Eplan Harness proD, can save significant time throughout the installation process. Rather than routing individual wires separately, which can be time-consuming and is high-risk for errors, the combined harness can be conveniently 'dropped in' as a single unit.

The ease of set-up facilitated by well-designed wire harnesses also reduces labour costs, since less time and expertise are required for installation. Over time, these cost savings can accumulate to significant figures, especially for large-scale or high-volume production environments.

Find Out More

EPLAN Harness proD helps users design fast and efficient cable harnessing solutions. To discover more about EPLAN's software solutions, please contact us today.

Comments