Author

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Ian Greeves

Ian has been working at EPLAN UK for almost 3 years as an Applications Engineer. Ian has previously worked in the maintenance department and in the pre-production department, designing and building semi and fully automated machinery. He wants to use his engineering skills and expertise together with EPLAN to enable customers to simulate, validate and optimise their electrical design applications to achieve their goals

greeves.i@eplan.co.uk

Ian Greeves auf LinkedIn

Major Efficiency Gains using Eplan: Hear from TJ Morris

TJ Morris Ltd are the parent company of Home Bargains, a UK discount retailer with more

|

Contents 2. EPLAN Implementation: a phased process 3. Benefits of EPLAN Standardisation |

than 500 stores. Following a sharp rise in sales during the pandemic, the company is expanding its estate, opening many new stores and improving sales at existing branches. To facilitate further growth, the company is automating all its warehouse storage facilities and optimising processes to ensure that they continue to deliver top brands to each store

daily, at low prices.

Having used Eplan Electric P8 for a number of years, the company invested in further Eplan solutions to support this expansion, with additional benefits to the business soon becoming apparent, including substantial time/cost savings.

Investments in a suite of Eplan software and services has given TJ Morris the opportunity to standardise working practices across its supplier base, improve the quality of its electrical drawings, and allow the business to bring the design in house, all this now ensuring better project delivery.

Automation in Action at the TJ Morris warehouse.

The Project

|

The Challenges

|

The Solutions

|

Eplan Implementation: A Phased Process

With more than 500 stores, the company is a lean, fast-growing retailer with a rapid stock turnover: an environment where time is definitely money.

Its value proposition - to deliver top brands at rock bottom prices - helped fuel a 13% increase in turnover to £2.8bn in 2020; levels not seen since it first opened its doors in 1976. “It‘s the busiest year we‘ve ever seen” says Matthew Mercer, Head of Engineering & Facilities.

To facilitate further growth the company has been automating all its warehouse storage facilities. Up to this point, its engineers had always relied on external subcontractors and project managers for its electrical design drawings. This process of outsourcing design was expensive and inconsistent, with TJ Morris engineers contending with drawings that varied in quality from individual suppliers. These were error-prone, which caused issues with implementation and, later, with on-going maintenance.

The company was already an Eplan customer, buts its decision to purchase more Eplan software and service solutions was driven by its need to:

1. Standardise working practices across its supplier base

2. Achieve greater time and cost-savings for the business

In what was described by Rob Garfoot, the Eplan Regional Sales Manager as “a phased and very-well planned programme”, the company implemented standardisation, upgraded to Eplan Pro Panel and Eplan Fluid, followed by staff training.

This investment across a range of Eplan solutions has not only improved working practices with suppliers: it has also meant the company’s engineers can now create their own electrical design drawings. They can easily update these drawings when they make modifications to the machinery.

-png.jpeg)

Benefits of Eplan Standardisation

The aim of standardisation is to define the workflow within a design process, clarifying company-wide principles to ensure the efficient implementation of a project.

Standardisation allows Eplan customers to partner more effectively with their suppliers or customers, by aligning resources, document layouts and working methodologies. The result is, inevitably, better productivity, design quality and consistent documentation.

TJ Morris has quickly begun to reap the benefits. Suppliers must now present Eplan standard drawings, which means they are laid out identically - making design approval quicker and easier. Eplan also generates and transfers all required information for purchasing as well as production, and automatically generates reports including bills of materials, cable schedules and parts lists.

Faster Panel Construction

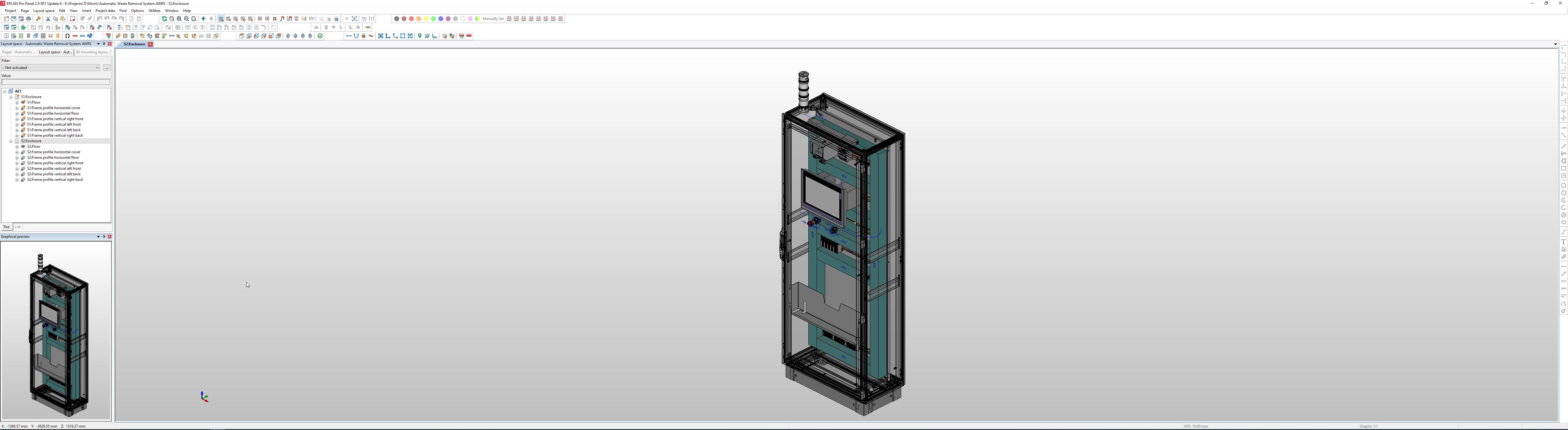

The introduction of Eplan Pro Panel means that TJ Morris engineers are now designing their own panels in a 3D environment, helping to cut the time needed to bring a project to fruition.

As part of the process, Eplan Pro Panel runs virtual project checks (as opposed to laborious manual tasks), so any issues, such as incorrect connections, can be easily identified and rectified before plans are signed off.

With in-house design, there is no longer any need to print-off designs and send comments back to suppliers in a protracted approvals process; something that used to also involve hiring external consultants. Instead, TJ Morris engineers now have the confidence to oversee the process themselves.

All told, Eplan Pro Panel has helped the company develop in-house capabilities, and delivered major savings through reducing project management fees.

A 3D control panel created in EPLAN Pro Panel

A 3D control panel created in EPLAN Pro Panel

Eplan Data Portal & Rittal's RiPanel

TJ Morris typically uses Rittal VX25 enclosures as the panel of choice, not least because Rittal currently have over 6,930 items in the Eplan Data Portal, but they’re also readily available in the Rittal RiPanel configurator, which is directly linked from within Eplan for the configuration of enclosure system and accessories.

“Macros are already in Eplan, and a lot of suppliers and parts information are contained within the Data Portal which saves the team time”, says Matthew.

“We don‘t have to build the parts database ourselves and ordering is a simple process, which involves simply exporting the parts lists. We take the enclosure specifications out of RiPanel and complete the panel design within Eplan. It really is a simple process and, once a panel is designed, we export and send the enclosure specification direct to Rittal for pricing. All in all, Eplan has saved us a great deal of time.”

Major Benefits of Eplan

The investment in Eplan solutions means that TJ Morris’ engineers now have a solid foundation for future expansion. And with the number of warehouses set to double by 2025, the focus has now shifted to expanding their panel building programme.

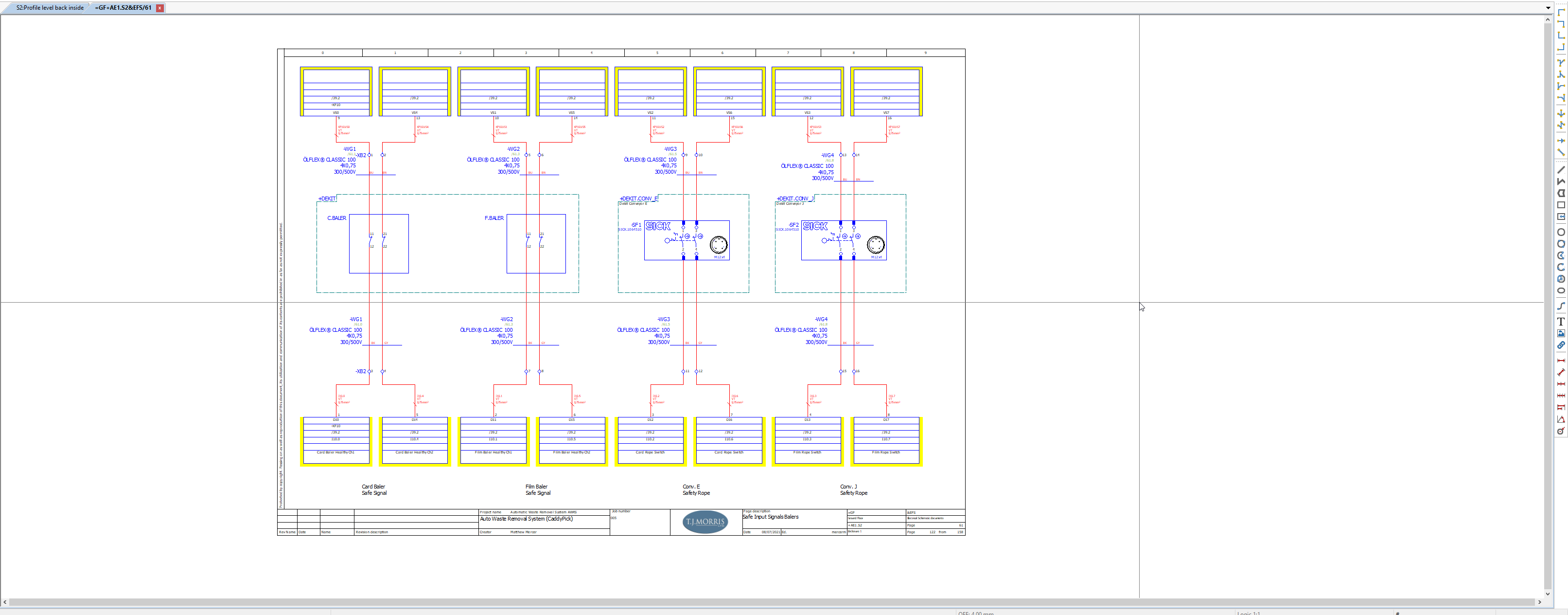

Schematics created in Eplan Electric P8

Matthew advises: “When we first bought Eplan, it was for small equipment modifications, but having done the training and implemented more solutions, we can see just what a powerful tool it is.”

“In an automated warehouse, any downtime can seriously impact the business, particularly as every one of our UK stores needs a daily delivery. In such a fast-moving environment we require optimal working practices. By using EPLAN, we‘re reducing fault-finding time, which has had a knock-on, positive impact on business continuity and operations costs”.

“The training is well-constructed, and I’ve been very impressed by the speed and quality of the response from EPLAN‘s support desk during the transition process.” Rob Garfoot, Eplan’s regional sales manager, concludes, “it shows how much you can achieve when you partner with the right company and are motivated to change.”

Do you want to learn more about how Eplan could help you achieve your specific goals? Request a software demo to show you which Eplan solutions will deliver the biggest efficiencies for both the engineers and the company as a whole.

.jpg)

Comments